A Mixproof Valve for Mill Filter

A technology of anti-mixing valve and filter device, which is applied in the direction of filtration and separation, fixed filter element filter, lifting valve, etc., which can solve the problems of unsatisfactory effect, insufficient decomposition of original pulp raw materials, insufficient stirring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following specific descriptions of the present invention are given by the examples, which are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

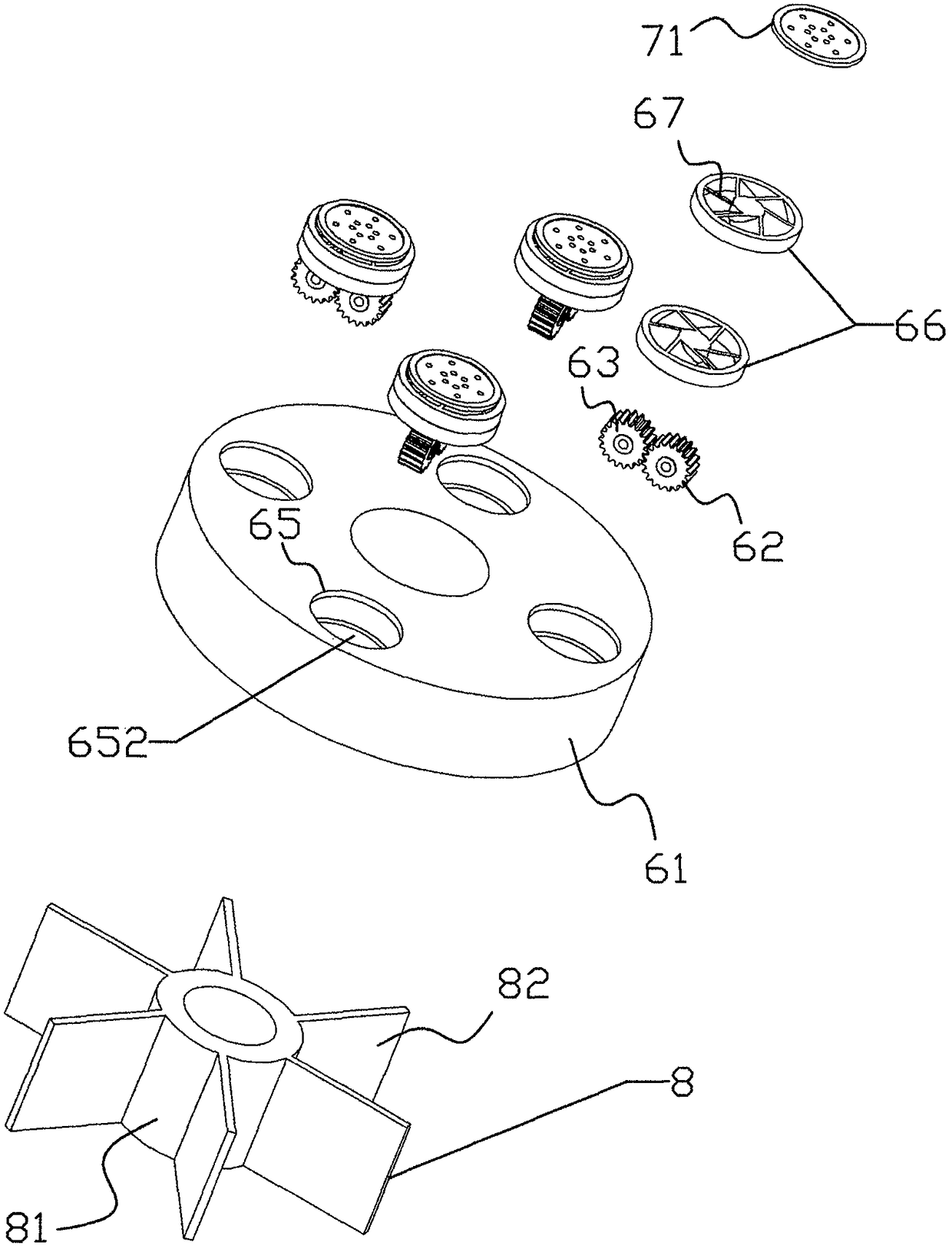

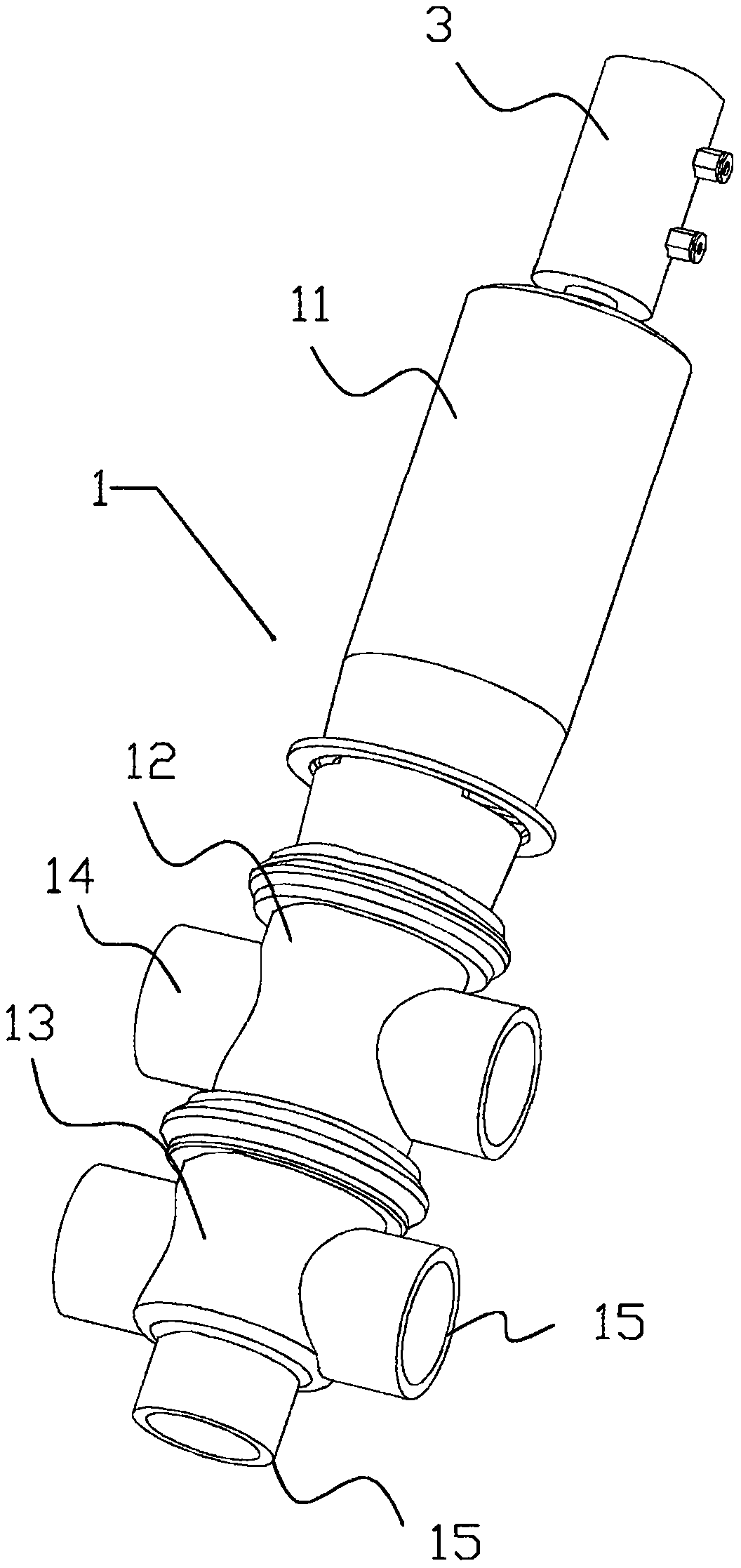

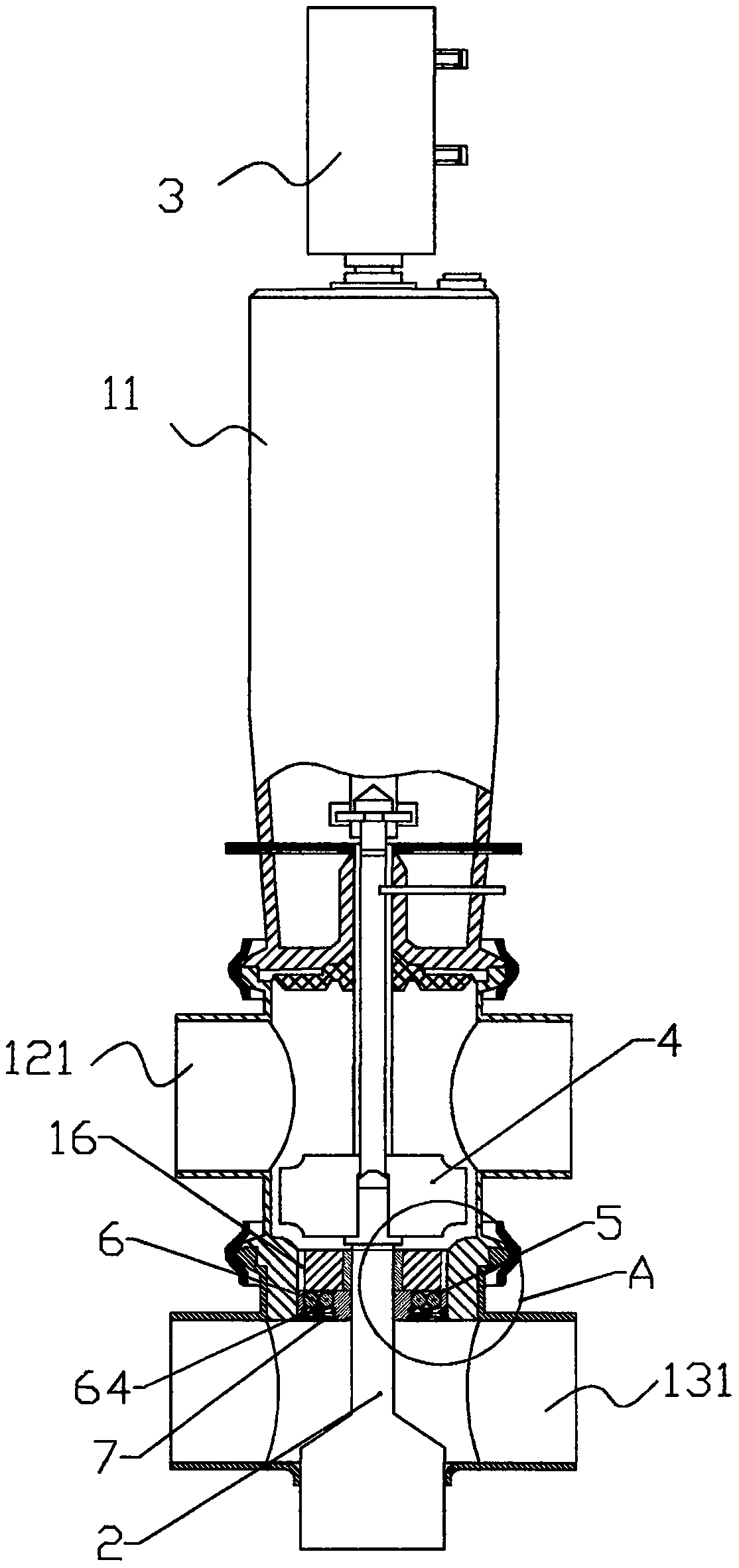

[0029] Such as Figure 1-6 The specific embodiment of the present invention shown is a crushing and filtering anti-mixing valve, which includes a valve body 1, and the valve body 1 includes a valve seat 11, an upper valve body 12 and a lower valve body 13, and the upper valve body 12 and the lower valve body 13 are respectively provided with a material inlet 14 and a material outlet 15 for the liquid medium to flow in or out, the upper valve body 12 is provided with a first flow channel 121, and the lower valve body 13 is provided with a first channel 121. Two flow passages 131, between the upper valve body 12 and the lower valve body 13, there is a conduction cavity 16 leading to the first flow passage 121 and the second flow passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com