Streamlined injection molding method for automobile parts and preparation equipment of streamlined injection molding method

A technology of auto parts and streamlining, which is applied in the direction of household components, applications, household appliances, etc., can solve the problems of uneven heating of workpieces, low production efficiency, poor product quality, etc., achieve high product quality, improve production quality and production efficiency , The effect of exempting the time of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

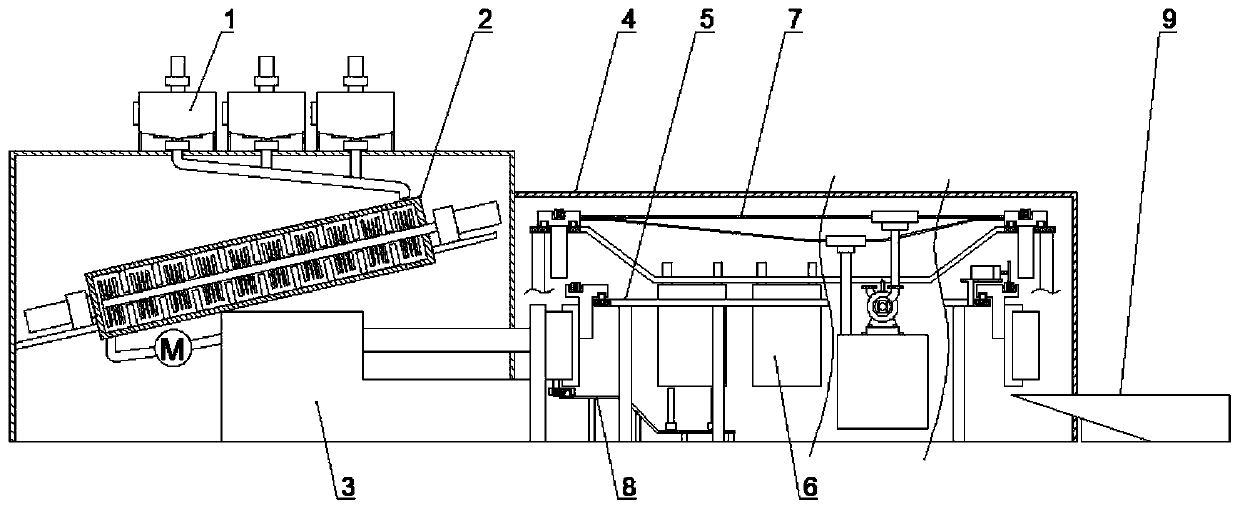

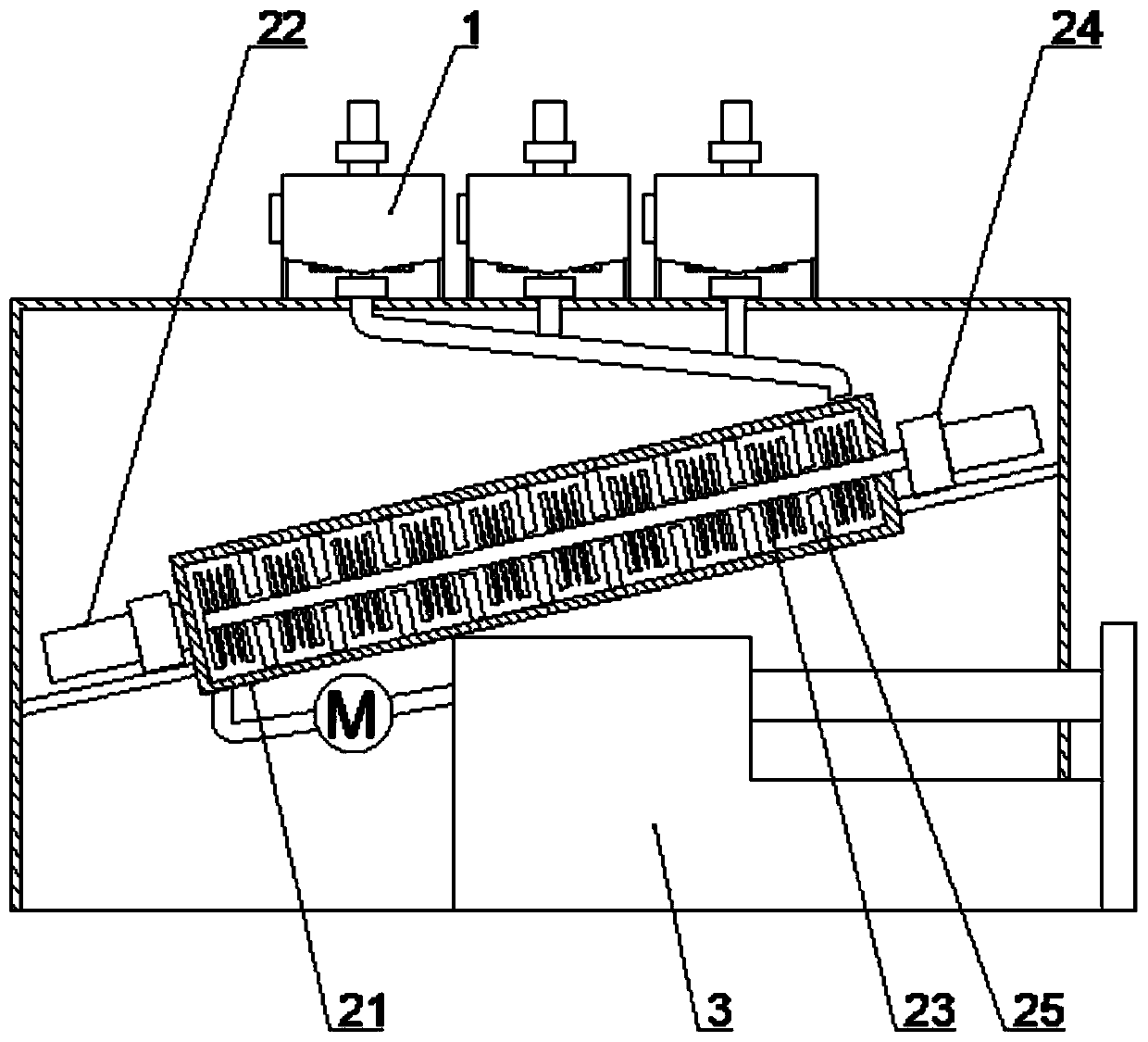

[0040] Such as Figure 1-5 A streamlined injection molding method for auto parts is shown, including batching, mixing and melting, injection filling, pressure holding, cooling and demoulding, specifically including the following steps:

[0041] Step 1: Pour the raw materials into the proportioning cabin 1, and the proportioning cabin 1 adjusts the ratio of a single material and sends it into the mixing cabin 2;

[0042]Step 2: The mixing chamber 2 mixes and melts the materials into a fluid, and sends them into the injection molding machine 3;

[0043] Step 3: The injection molding machine 3 heats the material, and sends the material into the mold cabin 4;

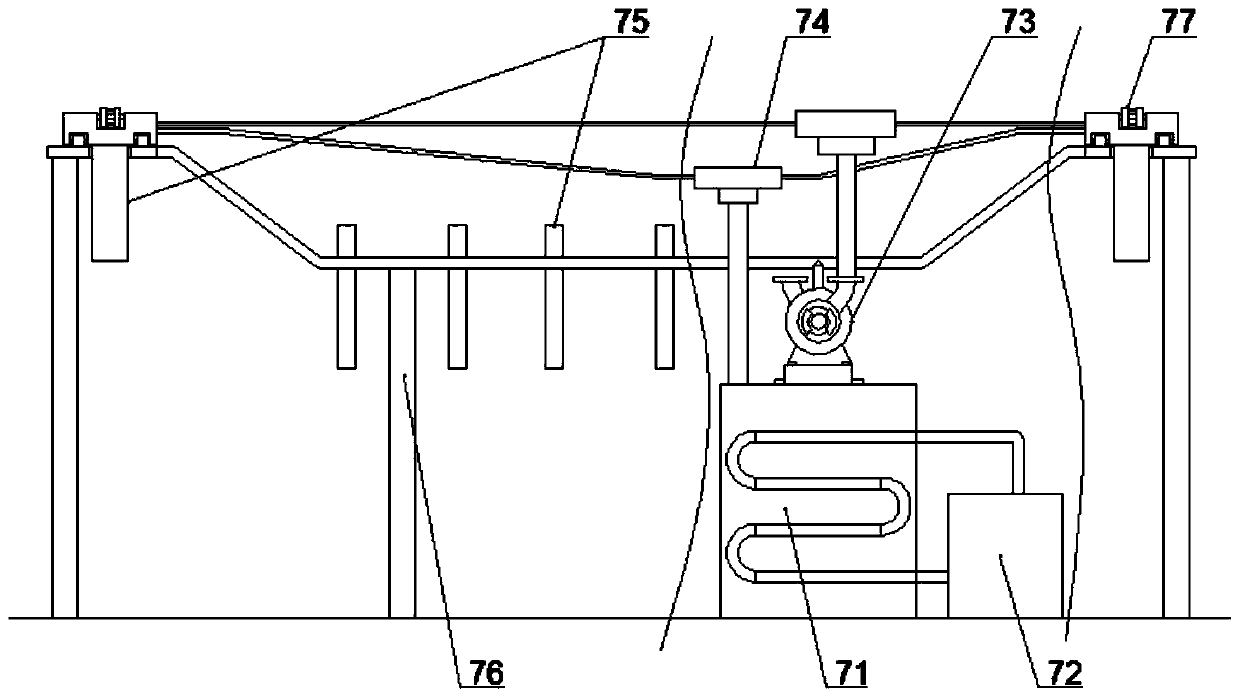

[0044] Step 4: the mold chamber 4 is provided with a mold circulation chain 5, mold tooling 6, water cooling chain 7, heat recovery chain 8 and lower material bin 9, the mold chamber 4 is provided with a mold circulation chain 5, the The mold circulation chain 5 is provided with mold tooling 6, and the mold tooling 6 is p...

Embodiment 2

[0055] Such as figure 1 A streamlined injection molding method for auto parts is shown, including batching, mixing and melting, injection filling, pressure holding, cooling and demoulding, specifically including the following steps:

[0056] Step 1: Pour the raw materials into the proportioning cabin 1, and the proportioning cabin 1 adjusts the ratio of a single material and sends it into the mixing cabin 2;

[0057] Step 2: The mixing chamber 2 mixes and melts the materials into a fluid, and sends them into the injection molding machine 3;

[0058] Step 3: The injection molding machine 3 heats the material, and sends the material into the mold cabin 4;

[0059] Step 4: the mold chamber 4 is provided with a mold circulation chain 5, mold tooling 6, water cooling chain 7, heat recovery chain 8 and lower material bin 9, the mold chamber 4 is provided with a mold circulation chain 5, the The mold circulation chain 5 is provided with mold tooling 6, and the mold tooling 6 is pro...

Embodiment 3

[0062] Such as Figure 1-2 A streamlined injection molding method for auto parts is shown, including batching, mixing and melting, injection filling, pressure holding, cooling and demoulding, specifically including the following steps:

[0063] Step 1: Pour the raw materials into the proportioning cabin 1, and the proportioning cabin 1 adjusts the ratio of a single material and sends it into the mixing cabin 2;

[0064] Step 2: The mixing chamber 2 mixes and melts the materials into a fluid, and sends them into the injection molding machine 3;

[0065] Step 3: The injection molding machine 3 heats the material, and sends the material into the mold cabin 4;

[0066] Step 4: the mold chamber 4 is provided with a mold circulation chain 5, mold tooling 6, water cooling chain 7, heat recovery chain 8 and lower material bin 9, the mold chamber 4 is provided with a mold circulation chain 5, the The mold circulation chain 5 is provided with mold tooling 6, and the mold tooling 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com