Method for detecting viscosity of emulsion paint and method for measuring temperature-viscosity correction factor

A technology of correction coefficient and measurement method, which is applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve problems such as time-consuming, and achieve the effect of shortening and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

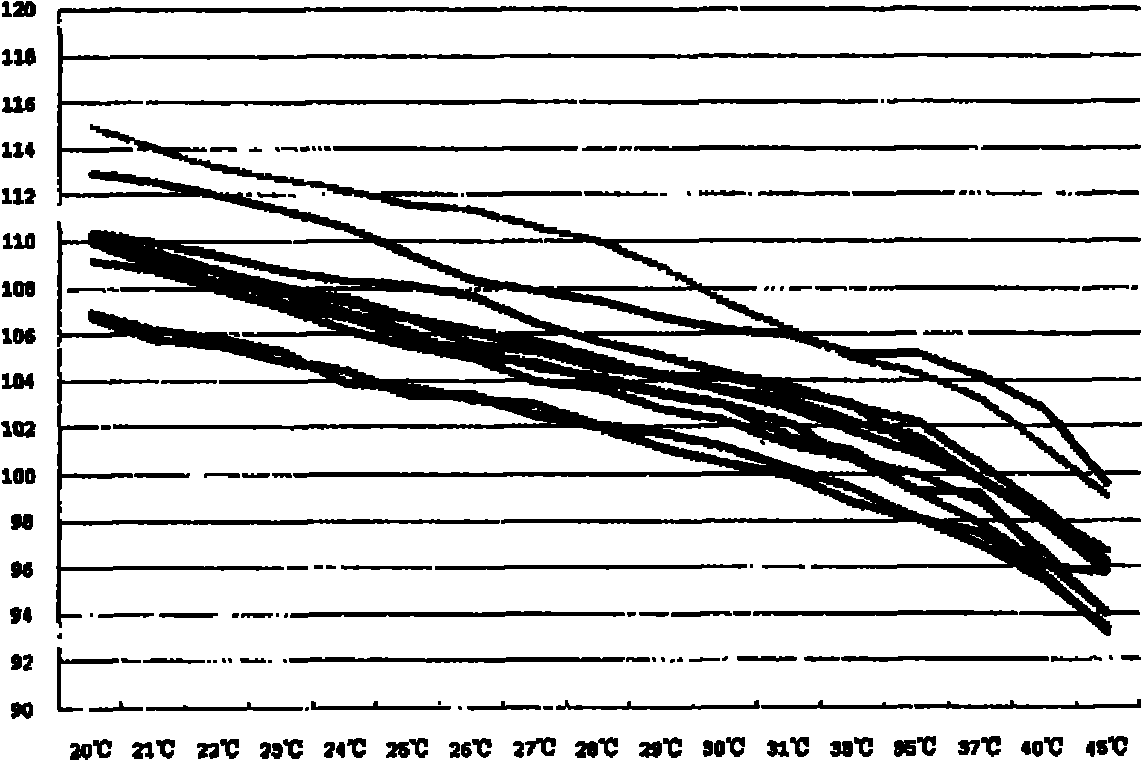

[0019] In the following examples, the viscosity is based on Krebs (KREBS) (KU) as the unit, and the Stormer viscometer is used as the detection instrument. The latex paint selected below belongs to medium viscosity architectural coatings, and is selected to be more representative The Meideli M600 (product model) was used as the test sample, and the temperature was adjusted by a water bath, and the viscosity values of the samples at each temperature point were tested for 10 batches of samples at a unit of 1 °C. The obtained data are shown in Table 1.

[0020]

[0021]

[0022] Table 1 temperature-viscosity table (Midley M600 product)

[0023] temperature °C

30℃

31℃

33℃

35℃

37℃

40℃

45℃

1

104.2

103.6

103.0

101.1

99.7

98.1

96.2

2

106.2

106.0

105.2

105.2

104.2

102.8

99.6

[0024] 3

100.5

100.0

98.8

98.1

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com