Automatic adaptive charger for AGV

A charger and adaptation technology, applied in electric vehicle charging technology, charging stations, motor vehicles, etc., can solve problems such as damage to plugs or charging heads, and achieve the effects of easy plugging and matching, simple structure, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

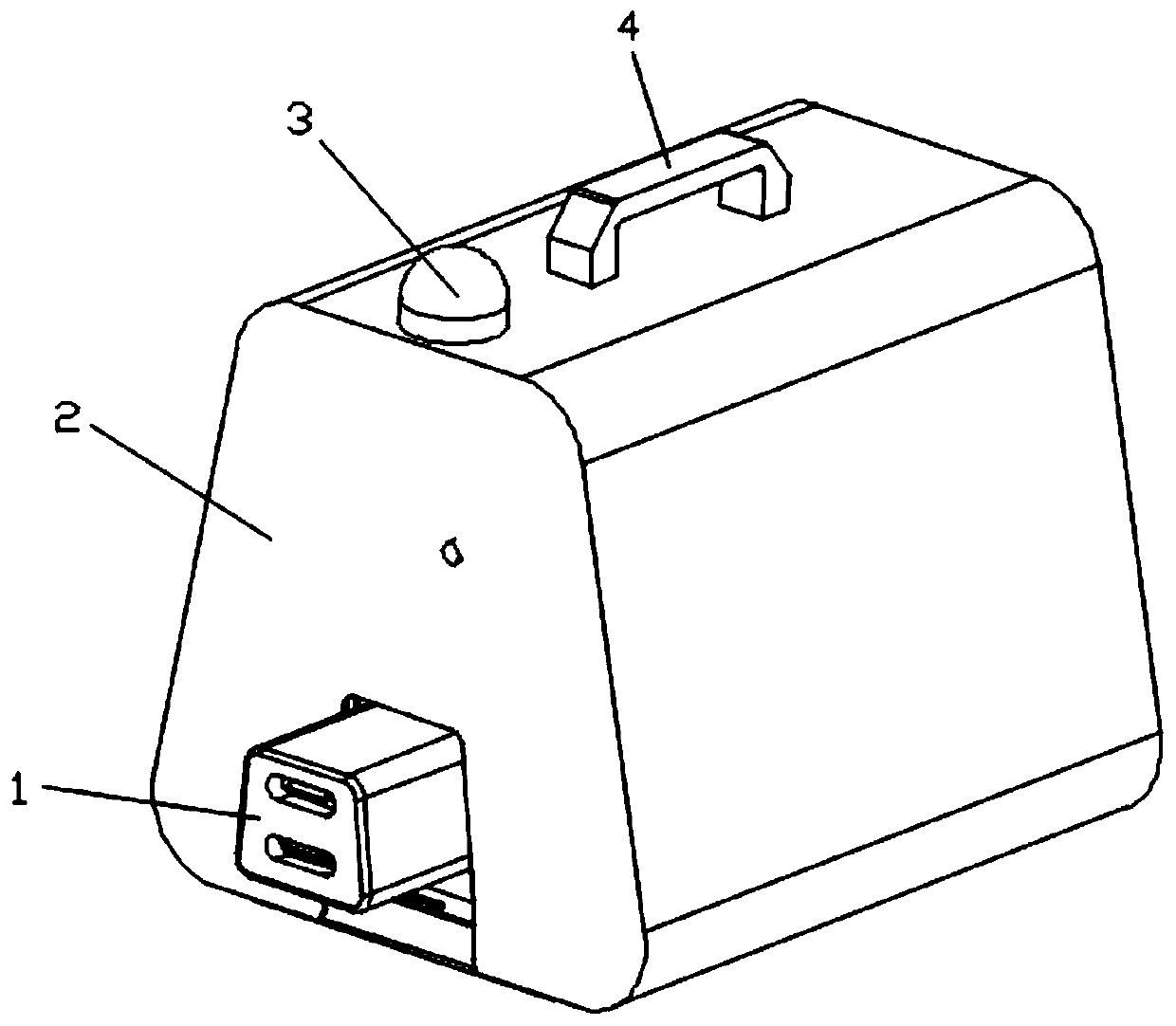

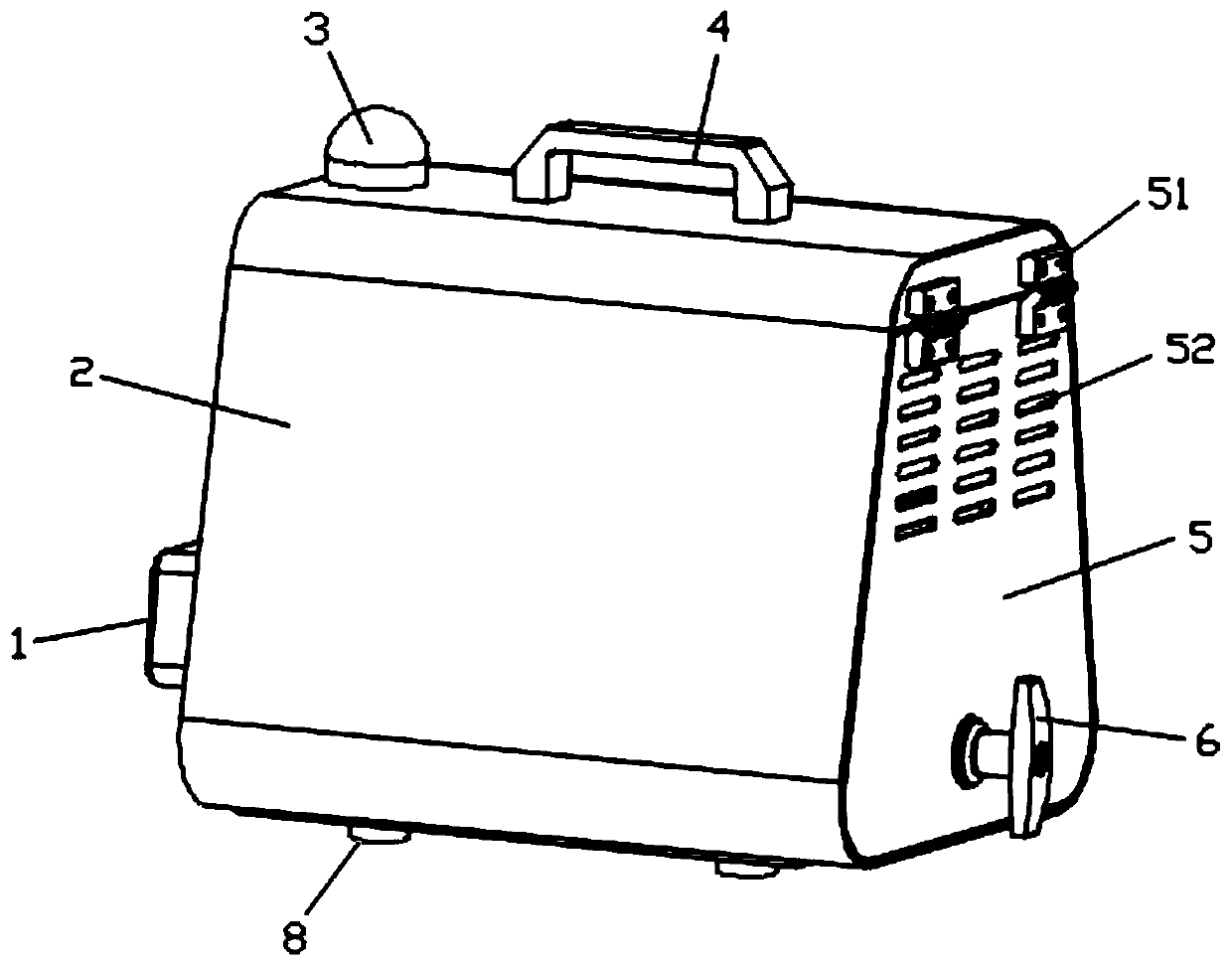

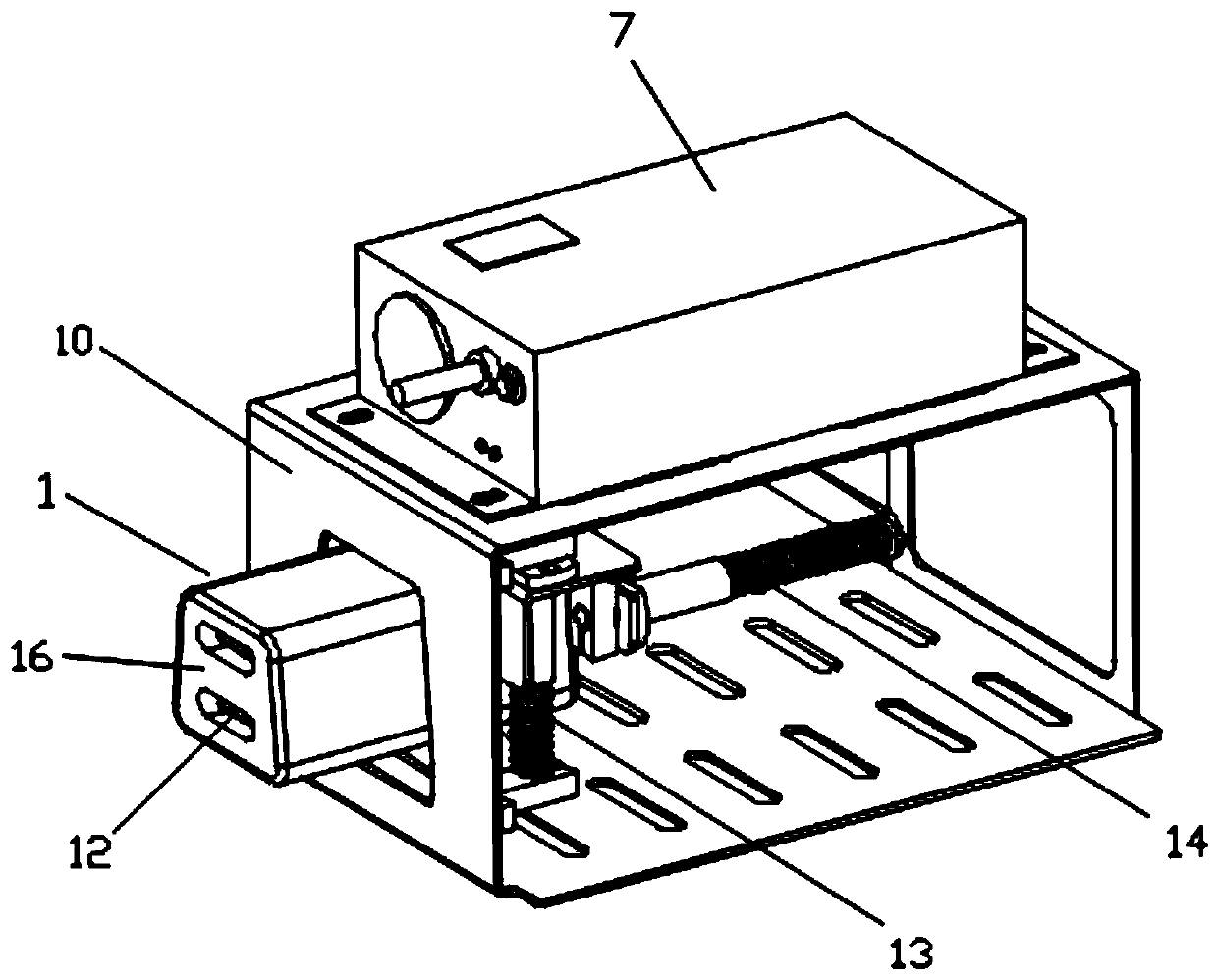

[0028] Such as Figures 1 to 7 As shown, an automatic adaptive charger for AGV includes a casing 2 and a cover 5. A charging head mechanism 1 and a charger 7 are fixed inside the casing 2. The charging head mechanism 1 includes a mounting frame 10 and a charging head mounting plate. 11. Charging head assembly 12, adaptive lifting assembly 13 and adaptive translation assembly 14, a pair of adaptive lifting assembly 13 is vertically placed on the mounting frame 10 through the first pillar 101, and the charging head mounting plate 11 is set on a On the self-adaptive lift assembly 13, a charging head assembly 12 electrically connected to the charger 7 is provided on one side of the side wall, and the charger can charge the AGV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com