Plug of back panel connector, shielding component, shielding plate of component and shielding pin thereof

A technology for backplane connectors and shielding components, which is applied in the direction of connecting parts, protective grounding/shielding devices, connections, electrical components, etc., can solve the problem of affecting the mating performance of backplane connector plugs, unstable axial positioning of shielding pins, The problem of warping and deformation of the shielding sheet is achieved by simplifying the structure and accuracy, firm and precise positioning, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

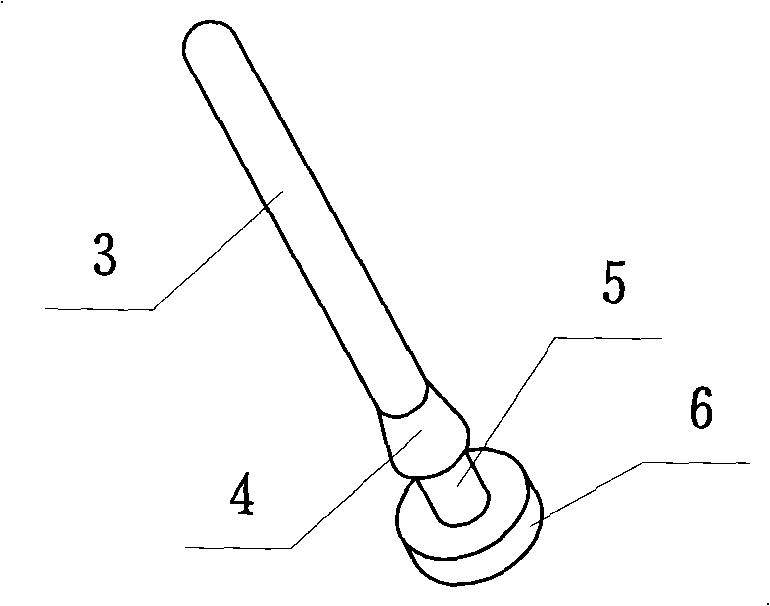

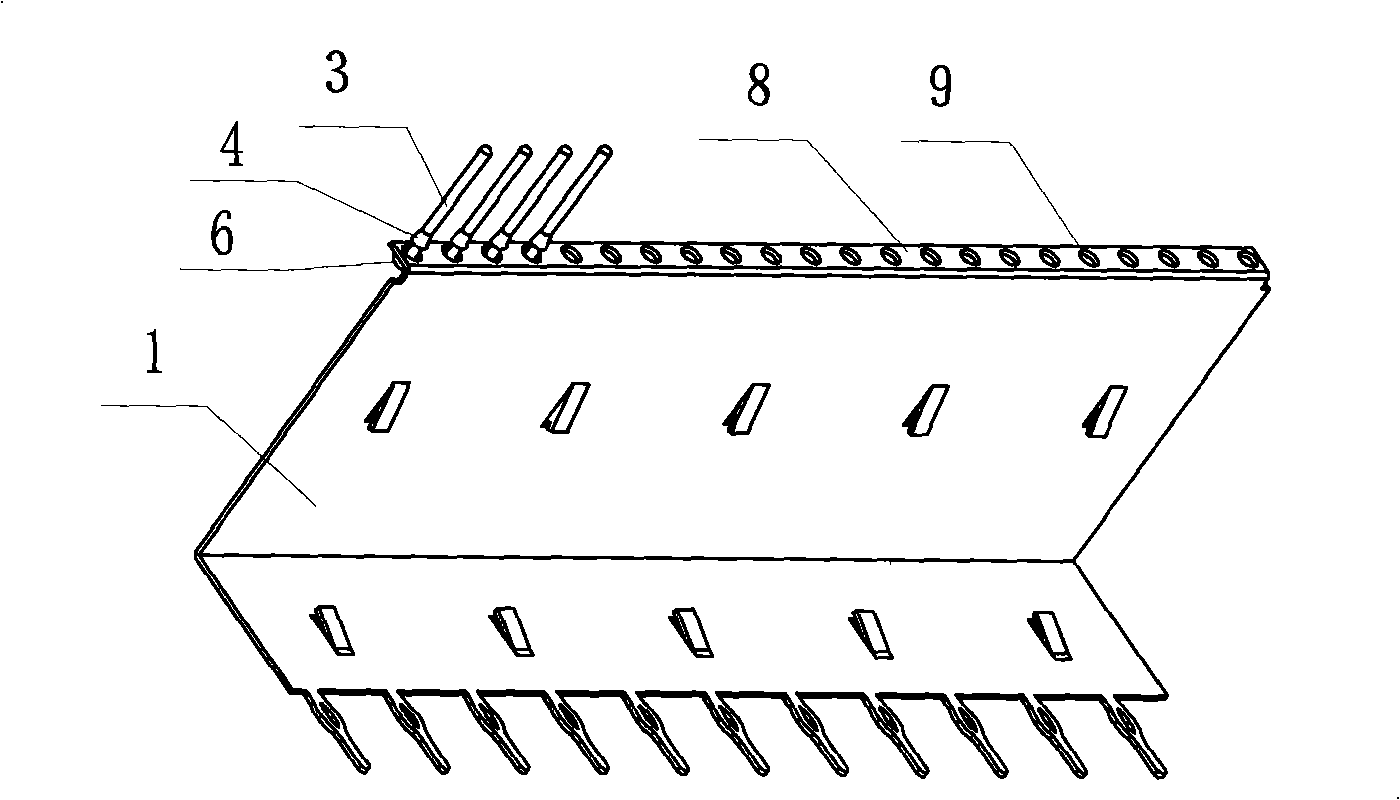

[0017] figure 1 Shown is the shielding pin of the shielding member of the backplane connector plug of the present invention. The shielding pin 3 includes a pin body. A backstop structure 4 is provided on the flange 6 at a set distance, and a neck 5 is formed between the backstop structure 4 and the stop flange 6, and the shielding pin 3 and the shielding piece and the plug in the backplane connector plug When the female seat is connected, the stop flange 6 and the stop structure 4 clamp the shielding pin 3 into the shielding pin socket on the juxtaposed plug socket and the shielding pin hole on the shielding sheet. The neck 5 is located in the shielding pin insertion hole and the shielding pin penetration. The above-mentioned anti-retraction structure 4 is an anti-retraction cone with a gradually larger diameter that is integrally extended from the surface of the pin body to the direction of the stop flange. Barbs instead.

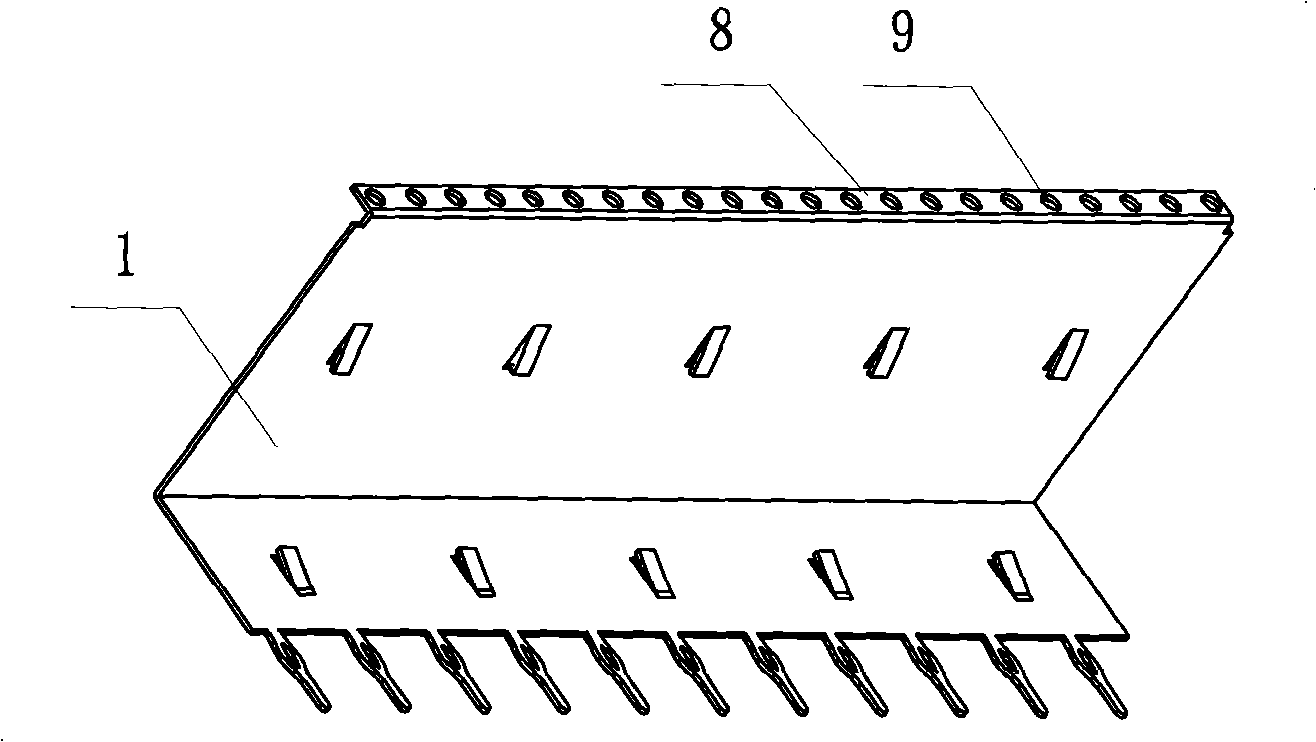

[0018] figure 2 Shown is the shielding piece of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com