A method of pasting frp cloth to enhance the impact resistance of concrete filled steel pipe piers

A steel pipe concrete, anti-impact technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of electric corrosion of steel pipes, affecting the reinforcement effect, etc., to achieve the effect of ensuring normal work, reducing deflection, and avoiding building collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

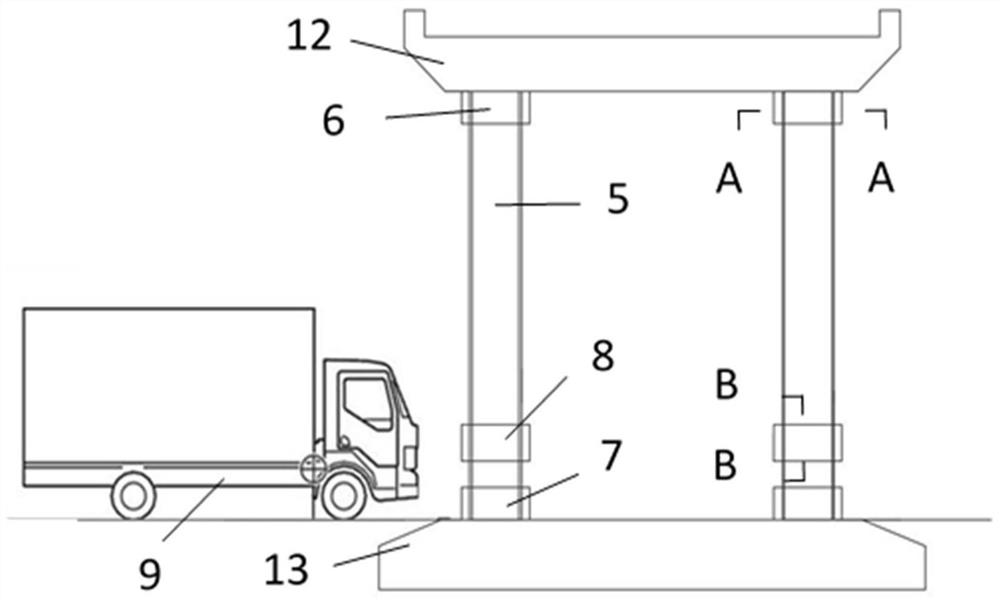

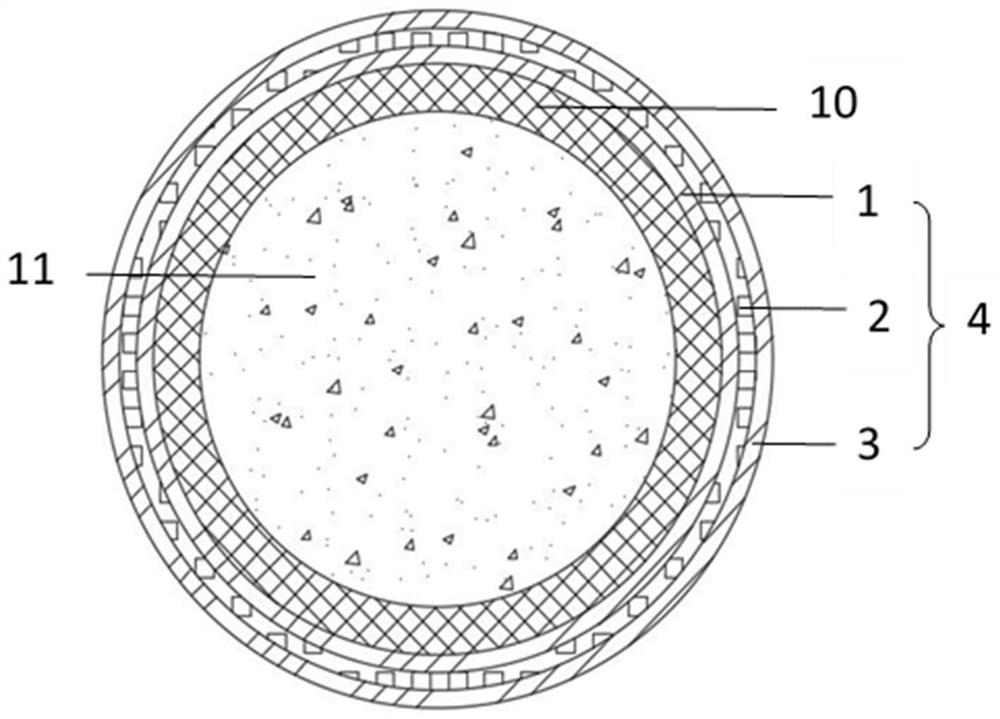

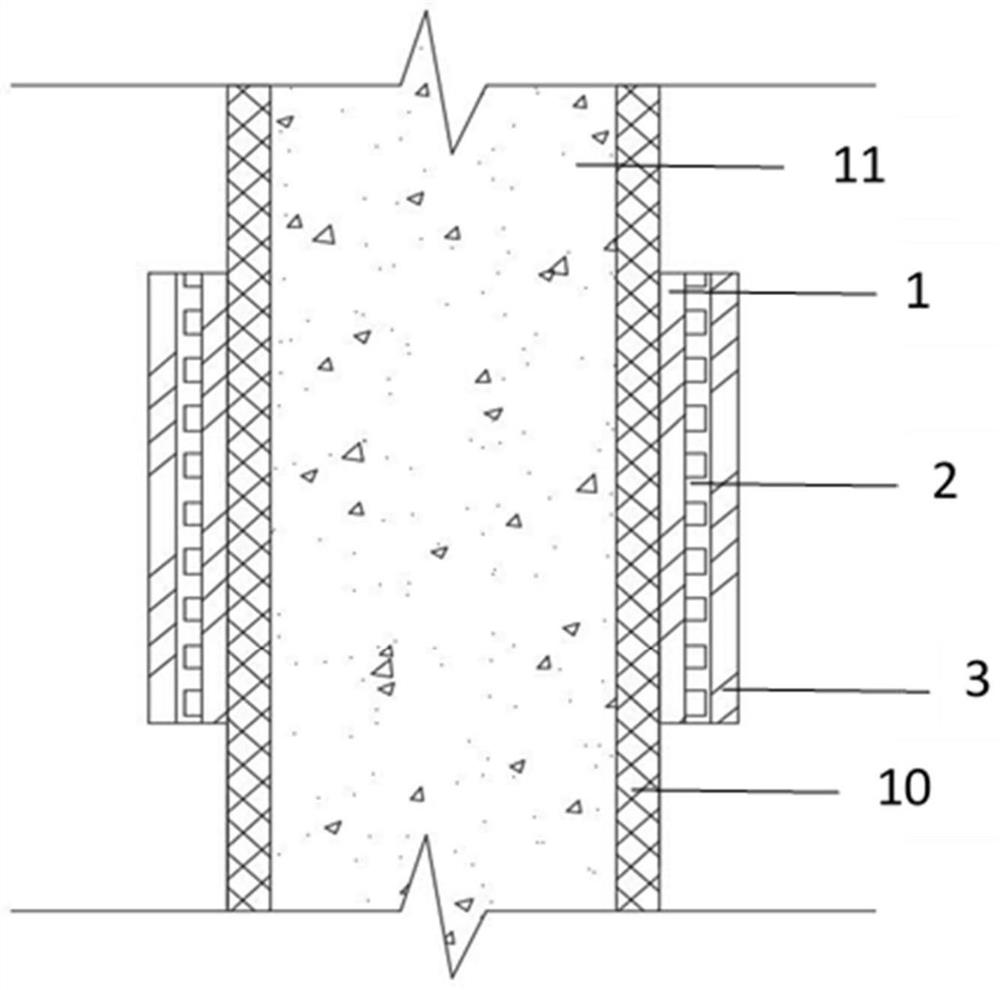

[0045] Such as Figure 1-3 As shown, the concrete-filled steel pipe pier 5 (φ600mm, steel pipe wall thickness 12mm) is at its location, and the maximum impact force that may be suffered comes from the impact of an 8.5t car out of control. The finite element program is used to calculate the When the vehicle 9 collides at a speed of 140km / h, the impact of the concrete filled steel tube pier 5.

[0046] In this embodiment, after calculation, under the impact of a vehicle 9 with a weight of 8.5t at a speed of 140km / h, the pier 5 does not produce plastic deformation, and only a small deflection occurs at the collision position 8, so the middle layer of CFRP cloth uses 1 layer, the winding positions are at the top 6 of the column, the foot of the column 7 and the collision position 8, and the winding width of the hybrid FRP cloth at the three places is 500mm. The column foot 7 is the part where the concrete-filled steel pipe pier 5 is connected to the lower foundation 13, and the c...

Embodiment 2

[0055] Such as Figure 1-3 As shown, the concrete-filled steel pipe pier 5 (φ600mm, steel pipe wall thickness 12mm) is at its location, and the maximum impact force that may be suffered comes from the impact of a 40t car out of control. Using the finite element program, the vehicle 9 with a weight of 40t is calculated at 140km / h The impact situation of the concrete filled steel tube pier 5 under the impact of speed h.

[0056] In this embodiment, it is calculated that under the impact of a vehicle 9 with a weight of 40 t at a speed of 140 km / h, the concrete-filled steel pipe pier 5 is seriously damaged, and cannot effectively support the superstructure. The impact situation of the concrete-filled steel pipe pier 5 when the mass of the vehicle 9 with a weight of 40 t is reduced to 20 t is calculated by simulation. When the impact occurred, the concrete-filled steel pipe pier 5 was not severely damaged. After the impact, the concrete-filled steel pipe pier 5 still had a support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com