Assembled special-shaped air duct for long-distance construction ventilation of tunnel and construction method

A long-distance, assembled technology, applied in mine/tunnel ventilation, tunnel, earthwork drilling and mining, etc., can solve the problems of reduced fan efficiency, long construction ventilation distance, and reduced air supply capacity, so as to increase the ventilation distance and reduce the Project investment, reduce the effect of enlarging the section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

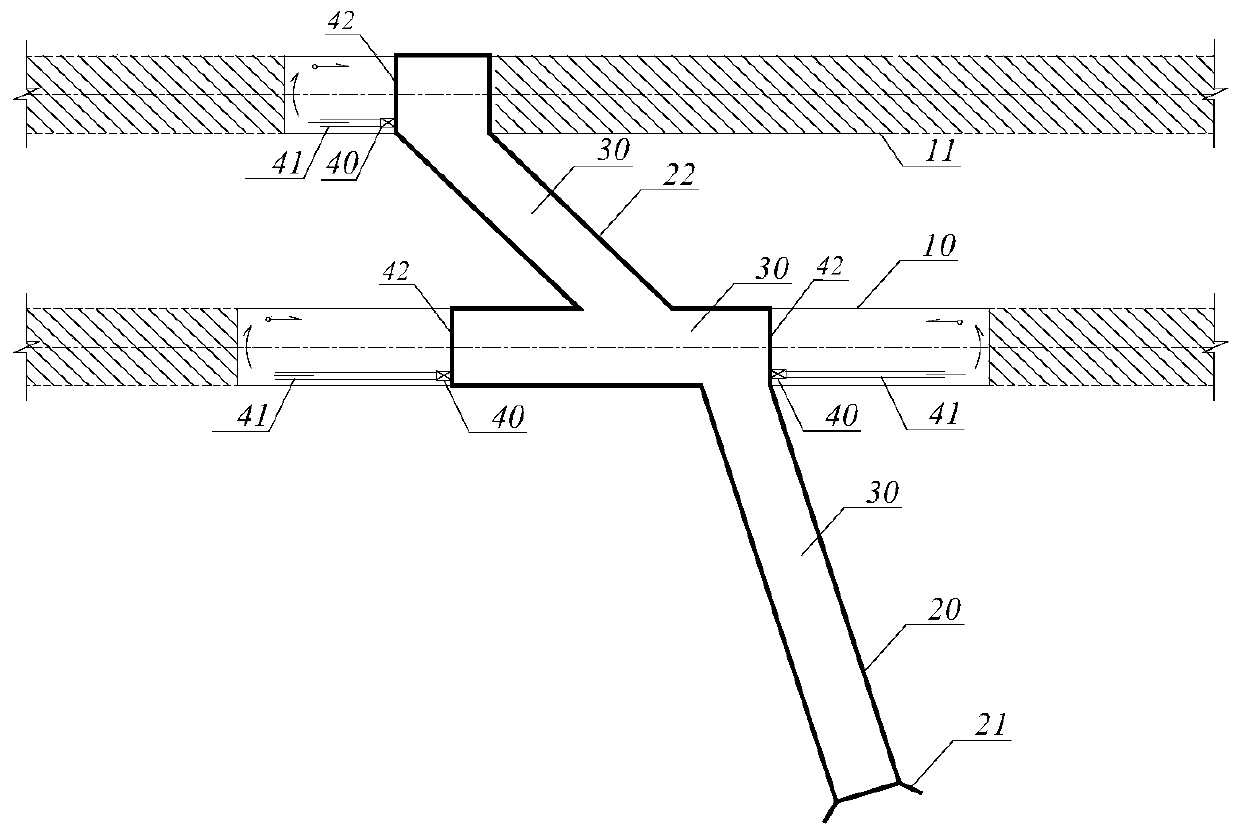

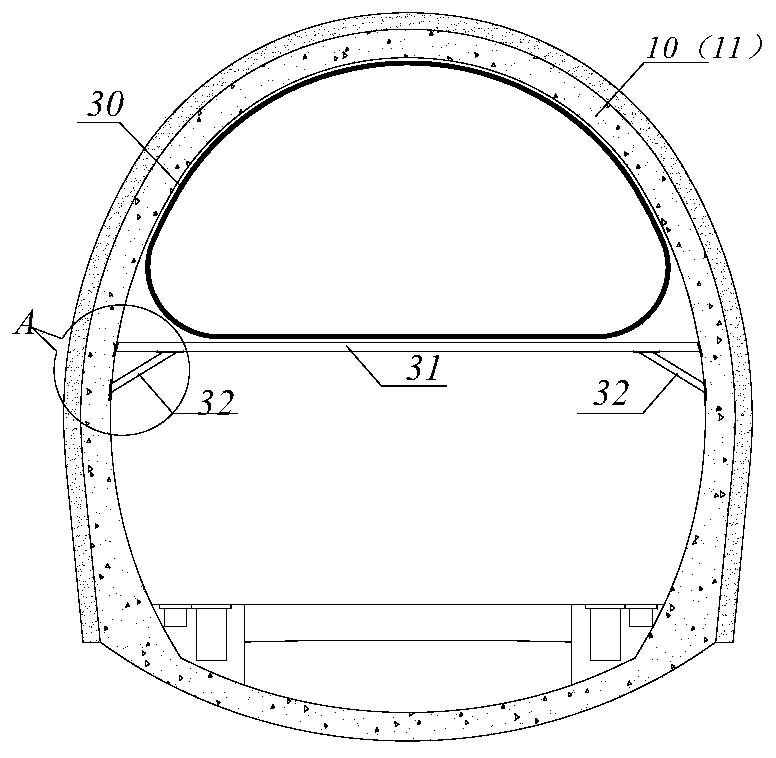

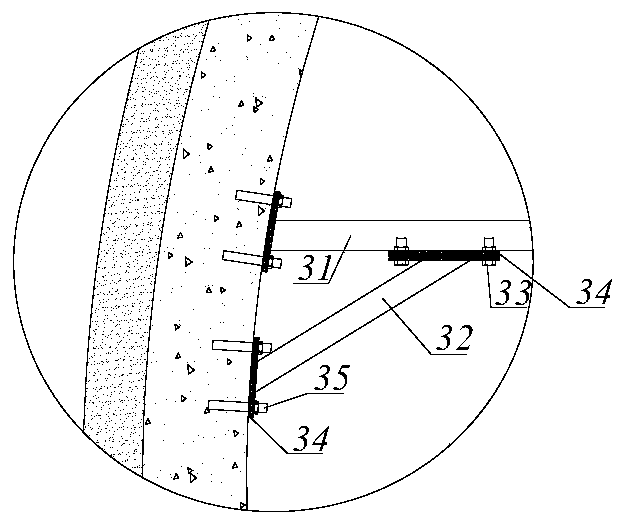

[0026] refer to figure 1 and Figure 4 , the present invention is an assembled special-shaped air duct for long-distance tunnel construction ventilation, including auxiliary tunnels 20 to supply air to the tunnel excavation surface of the right-line main tunnel 10, and through the transverse channel 22 to the left-line main tunnel or parallel guide tunnels 11 air supply to tunnel excavation face. The middle and upper parts of the auxiliary tunnel 20, the right-line main tunnel 10, the cross passage 22, and the left-line main tunnel or parallel guide tunnel 11 are fixedly installed with a customized lightweight air duct 30 for fresh air flow outside the cave to pass through. 30. Set the end partition 42 on the port of the tunnel excavation surface adjacent to the right-line main tunnel 10, the left-line normal tunnel or the parallel guide tunnel 11 to form an air cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com