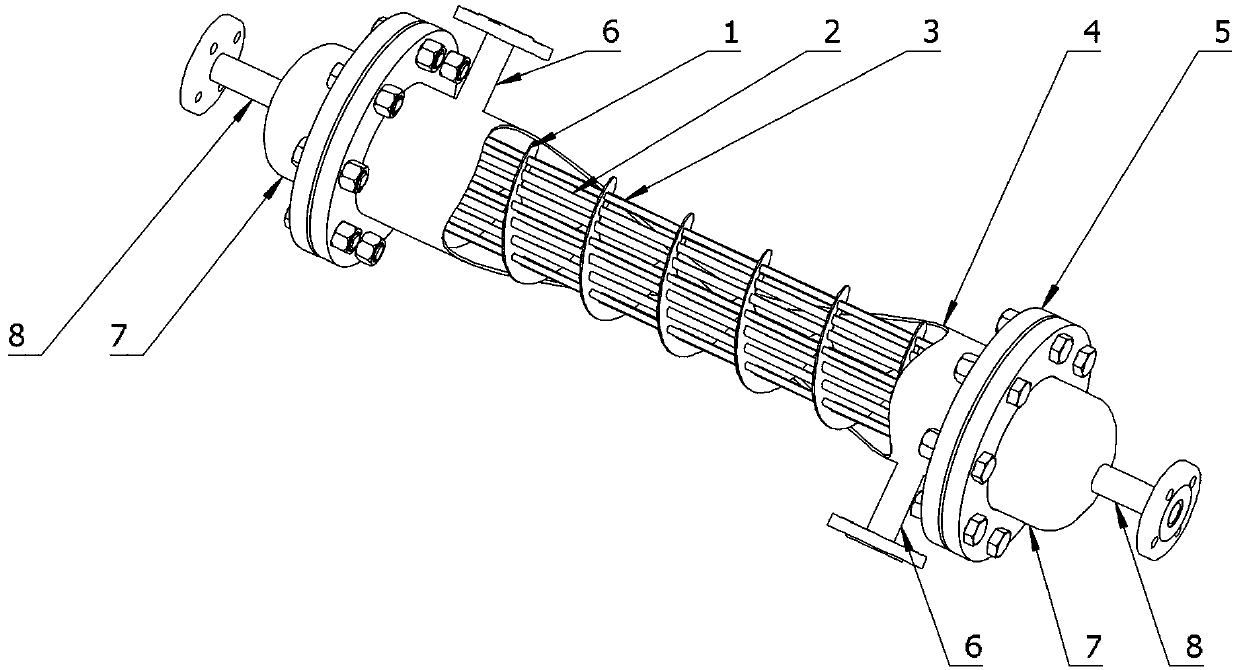

Continuous spiral baffle plate shell-and-tube heat exchanger

A technology of shell-and-tube heat exchangers and spiral baffles, which is applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., and can solve complex fin arrangement positions, complex splicing, production and processing difficulties And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

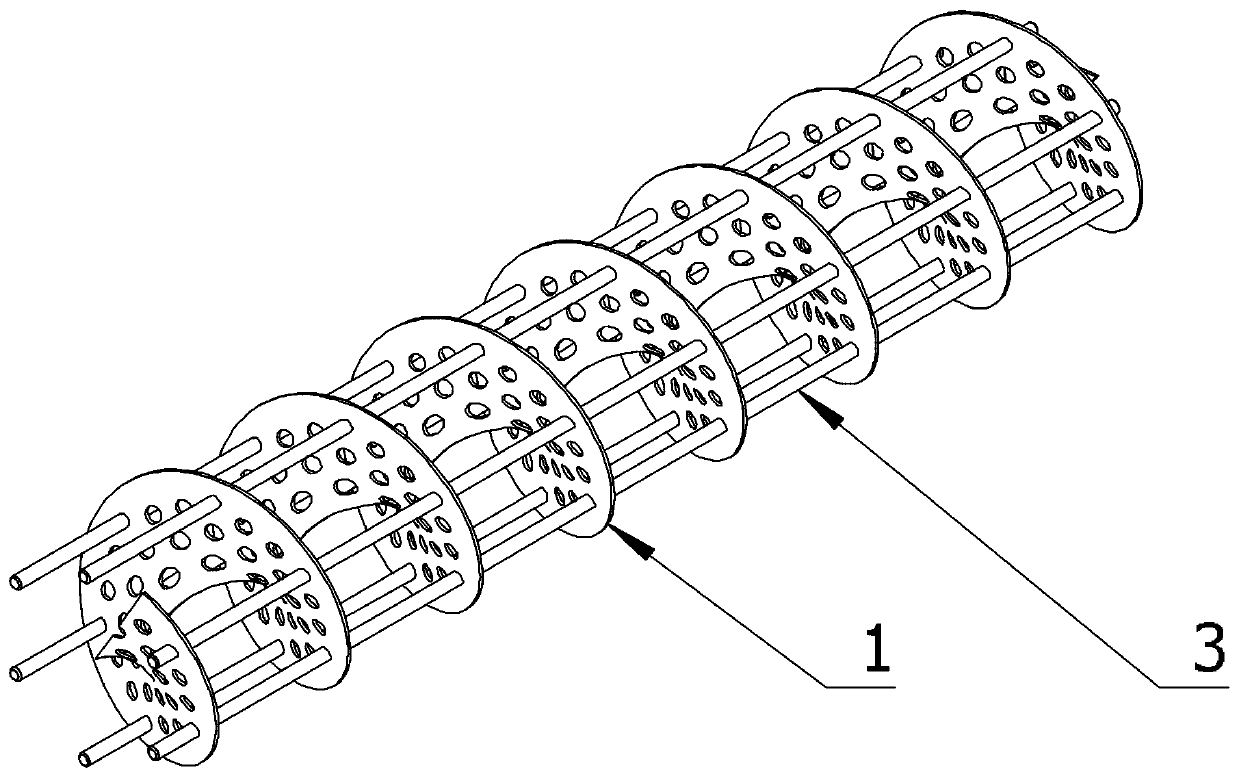

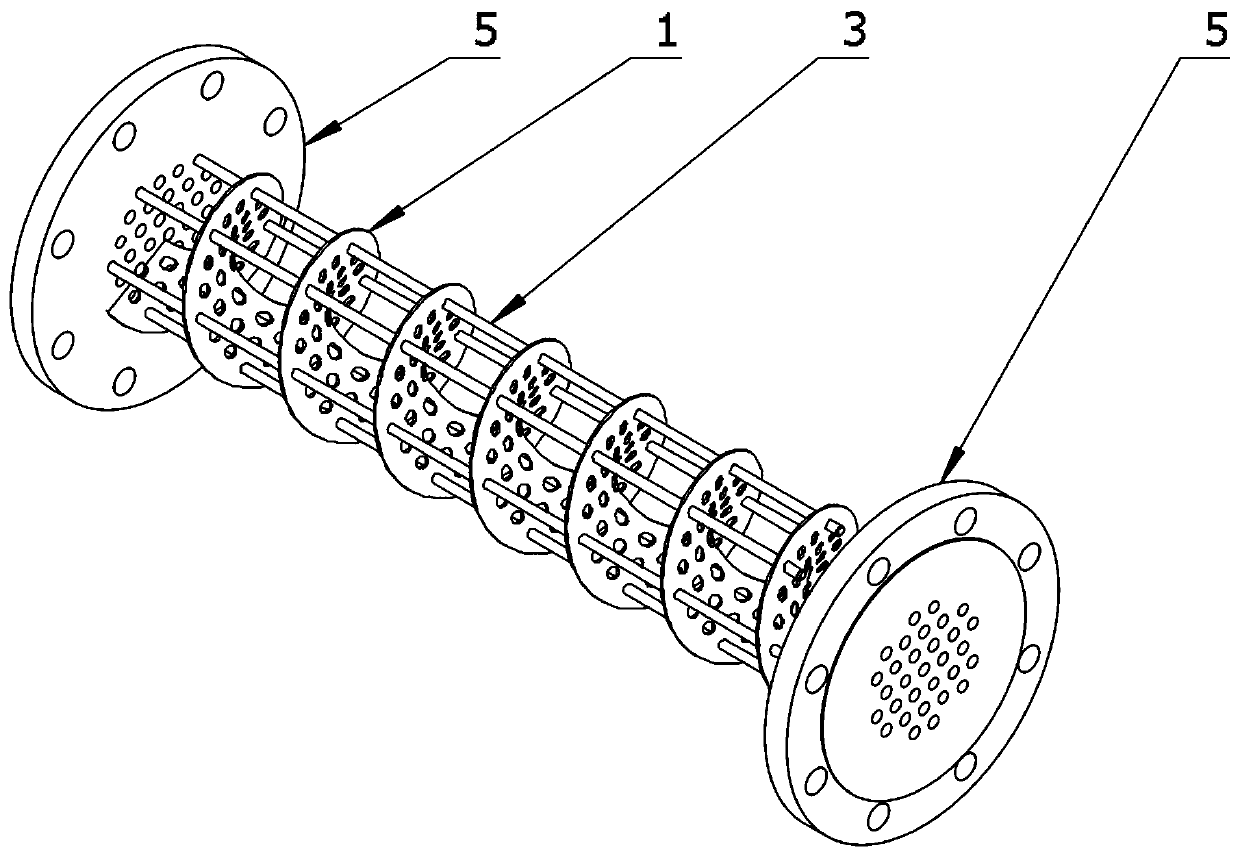

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. In order to ensure that the tube holes of the tube sheet and the multi-piece spiral baffles are concentric, first, a plurality of heat exchange tubes are temporarily penetrated through the tube sheet and the multi-piece baffles to play a limiting role, and then the space between the spiral baffles , The spiral folded willow plate and the tube sheet are firmly fixed, and the temporary heat exchange tube can be taken out or not taken out, the baffle fixing assembly fixes the spiral baffle and the tube sheet to the holes,, the baffle fixing assembly The combination structure of traditional tie rods and spacer tubes can be used, or the welding structure of profiles and spiral baffles, or the slotted limit structure of profiles can be used. The spiral baffle is composed of multiple spiral plates, and the combined joints can be welded or not....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com