A multifunctional integrated condensing evaporator for a cascade refrigeration system

A technology of condensing evaporator and cascade refrigeration, applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problem of shortening the service life of heat exchanger, large amount of working medium, and excessive temperature difference of heat exchanger. and other problems, to achieve the effect of eliminating the influence of temperature difference stress, high utilization rate of heat exchange area, and improving system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

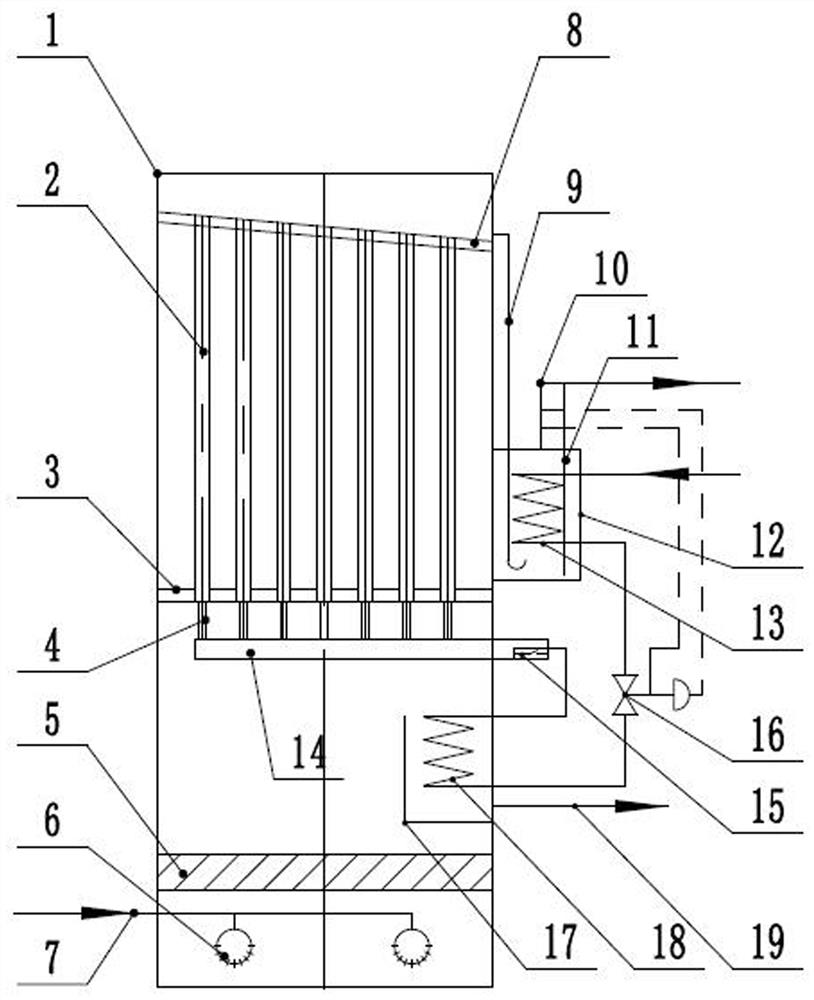

[0026] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0027] Such as figure 1 , a multifunctional integrated condensing evaporator for a cascade refrigeration system, comprising a shell 1, an upper tube plate 8 and a rectifying layer 5 are arranged in the shell 1 from top to bottom, and the inner cavity of the shell 1 is divided into Return air chamber, upper heat exchange chamber and lower heat exchange chamber from top to bottom. Wherein, the upper tube sheet 8 is set at an inclination of 5°.

[0028] The condensing evaporator also includes an inlet pipe 7 communicating with the lower heat exchange chamber and a liquid outlet pipe 19 communicating with the upper heat exchange chamber. Specifically, the air intake pipe 7 communicates with the rotary diffuser 6 installed in the lower heat exchange chamber. The upper heat exchange chamber is also provided with a deflector 17 located below the heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com