Flue gas denitration control method with future NOX emission prediction function

A control method and emission technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of PID control lag, large disturbance, large delay, etc., and achieve the effect of solving hysteresis overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the drawings and embodiments.

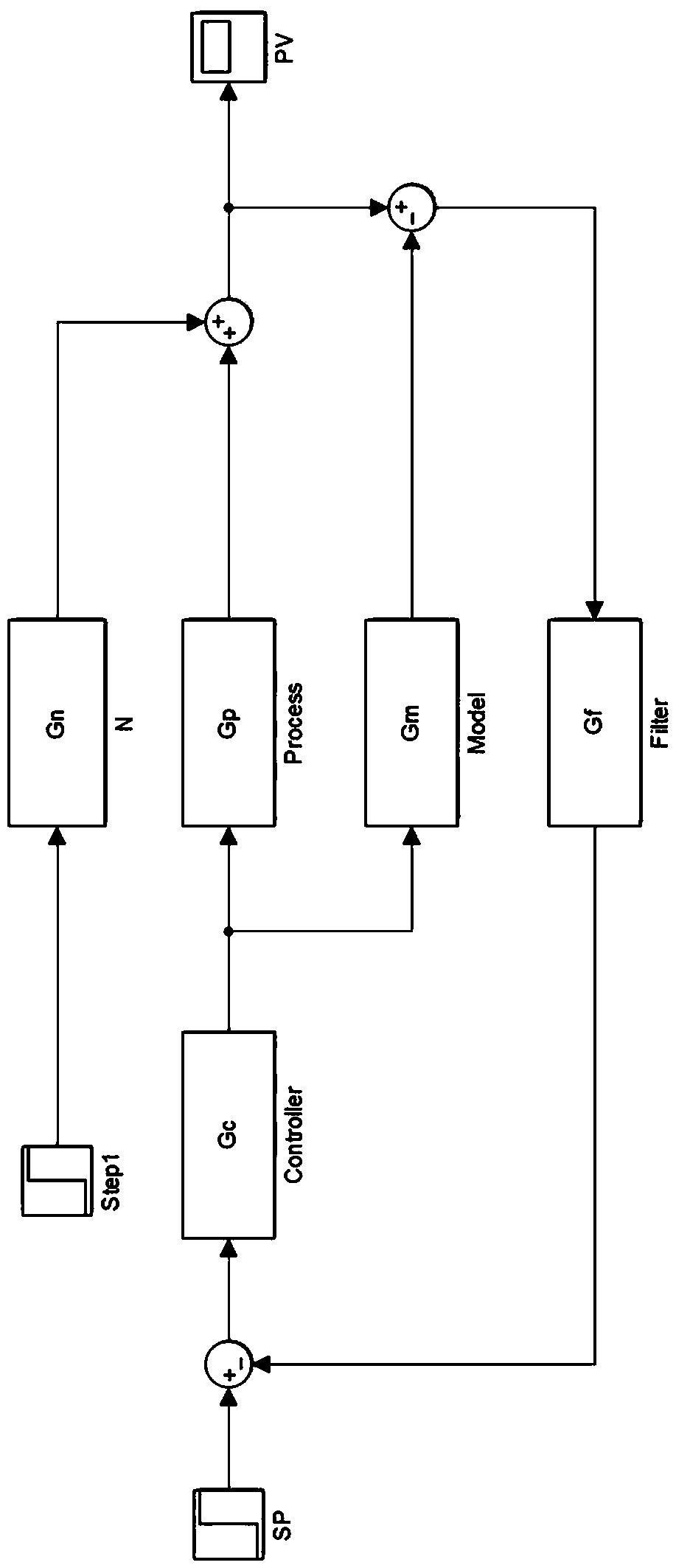

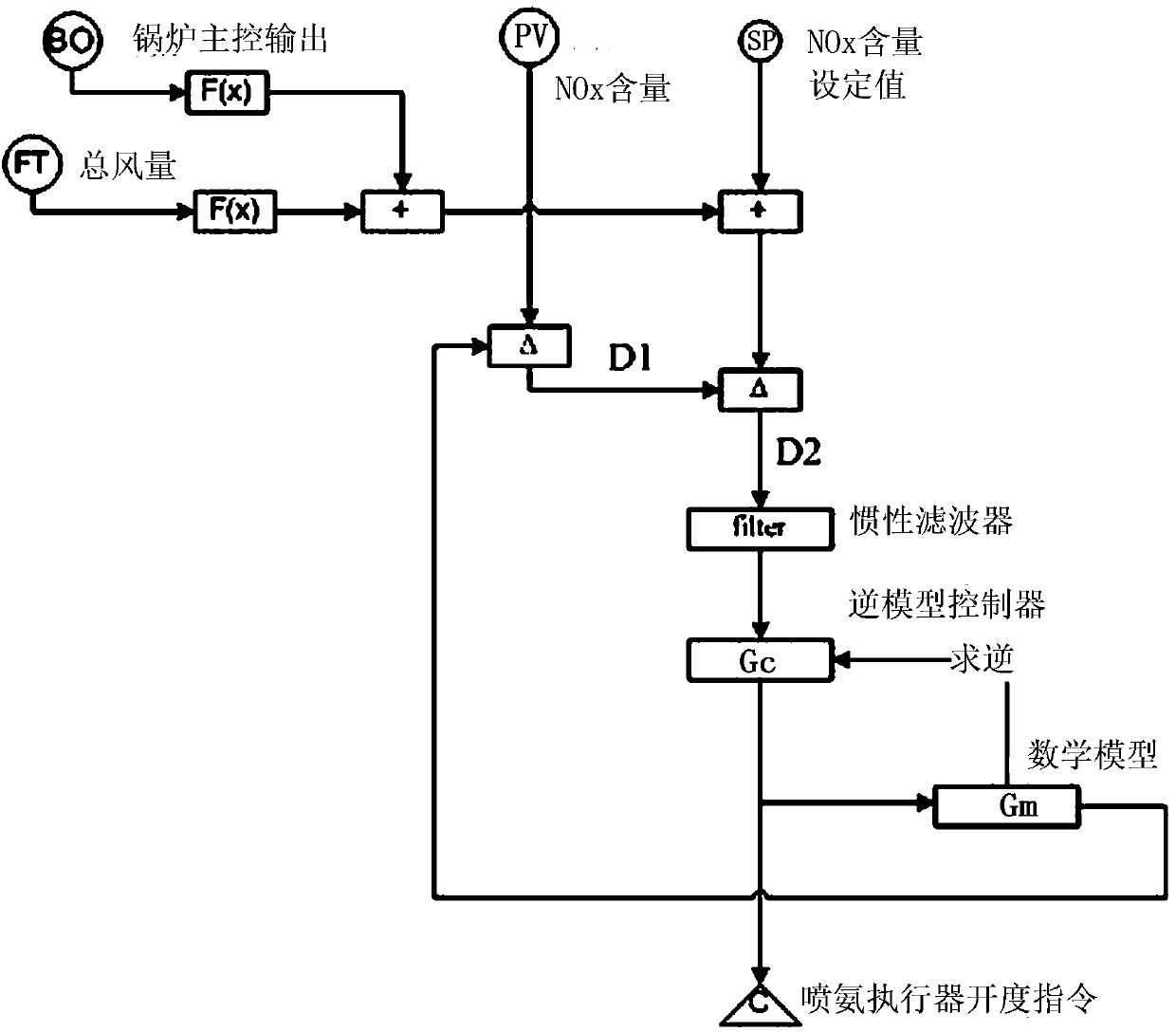

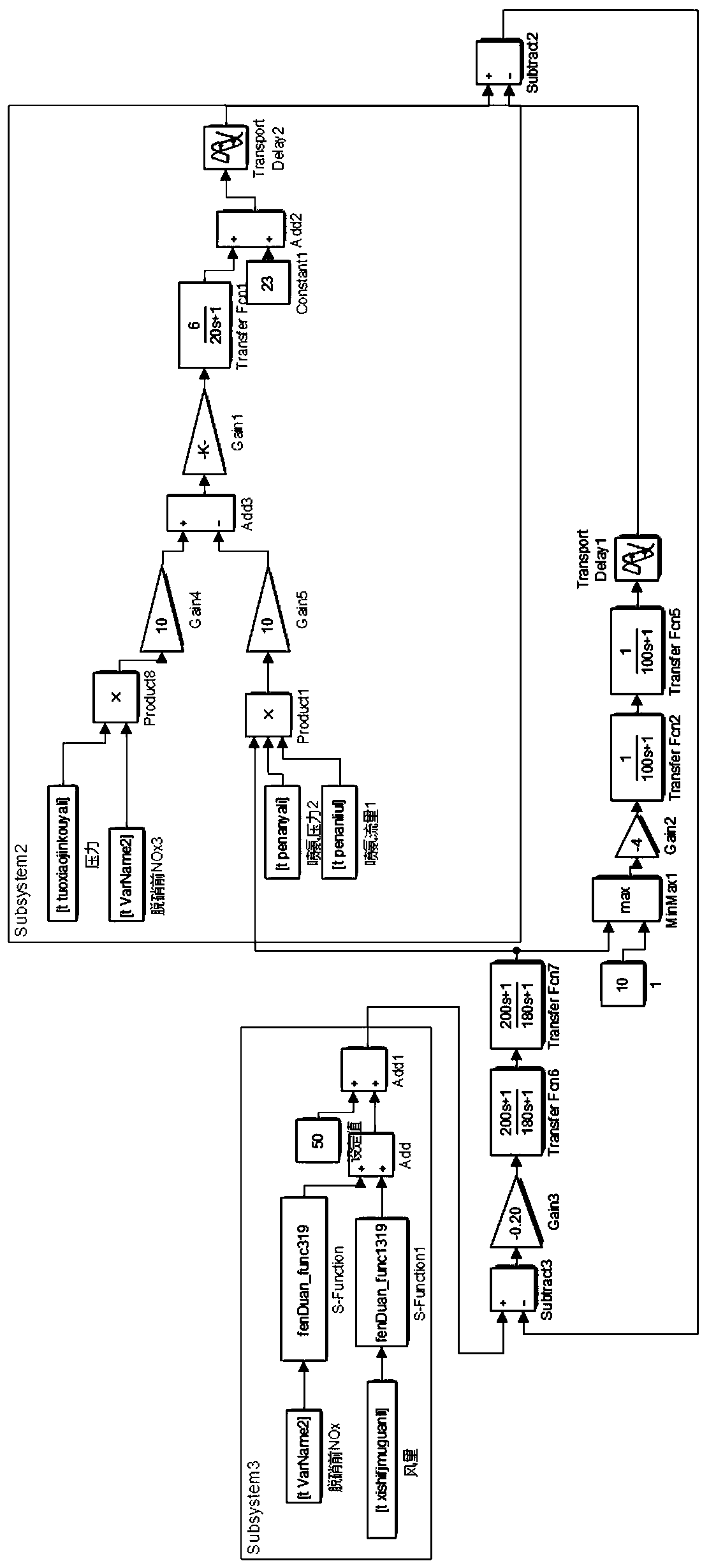

[0030] Such as figure 1 with figure 2 As shown, the control principle diagram and the SAMA engineering configuration diagram of the flue gas denitration control method with the future NOx emission prediction function of the present invention are respectively given, figure 1 Where SP is the set value of NOx emissions, G c Is the model controller, G m Is a mathematical model, G p To control the industrial process of NOx emissions, G n In order to cause the disturbance of NOx emissions, STEP1 is the disturbance source; PV is the industrial process G p And the disturbance process G n The superimposed amount of, which is detected by a sensor or transmitter. figure 2 Among them, BO is the boiler main control output, FT is the total air volume, F(X) is the function, + is the addition, Δ is the deviation (difference), FILTER is the inertial filter, and C is the ammonia inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com