A freeze dryer cleaning collection structure with internal impurities

A freeze dryer and impurity technology, which is applied in the field of freeze dryer cleaning and collection structure for internal impurities, can solve the problems of difficult recovery of overflow products and small cleaning range, and achieve fast and convenient swing operation, good effect and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It is only the preferred embodiments of the present invention as described below, and the scope of the invention is not limited.

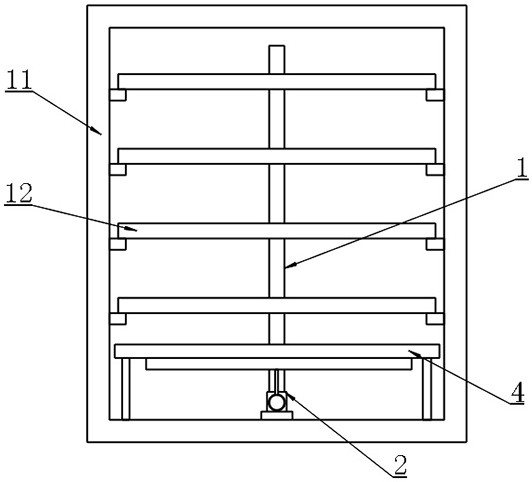

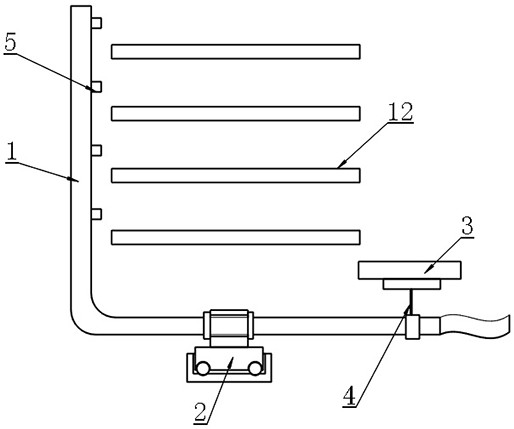

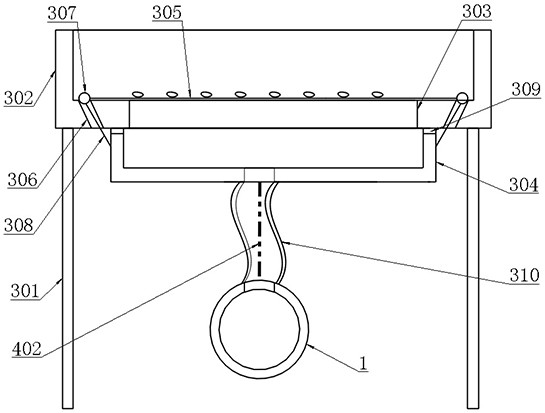

[0027] Example: figure 1 , 2 , 3, 4, 5, 6, 7 and attached Figure 8 As shown, a lyophilizer is cleaned with an internal impurity cleaning collection structure, which is provided in the lyophilized chamber 11 and the lateral tube is located below the material frame 12, and the vertical tube is located in the inner side of the material frame 12 and an outer water pump hose. The tubular body 1 is provided on the bottom surface of the frozen chamber 11 and is provided in the rotating seat unit 2 of the center of the L-type pipe body 1 to be used as the transverse tube casing. On the bottom surface of the dry chamber 11 and located outside the material frame 12 and for receiving the collecting frame unit 3 of the cleaning water flow under the material frame 12, disposed on the transverse tube and by connecting the charge frame. The unit 3 is surface m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com