Surface acoustic wave device with unidirectional transducer

A surface acoustic wave and converter technology, applied in the direction of instruments, electrical components, sound-generating devices, etc., can solve problems such as manufacturing difficulties, high operating frequency, and short operating wavelength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

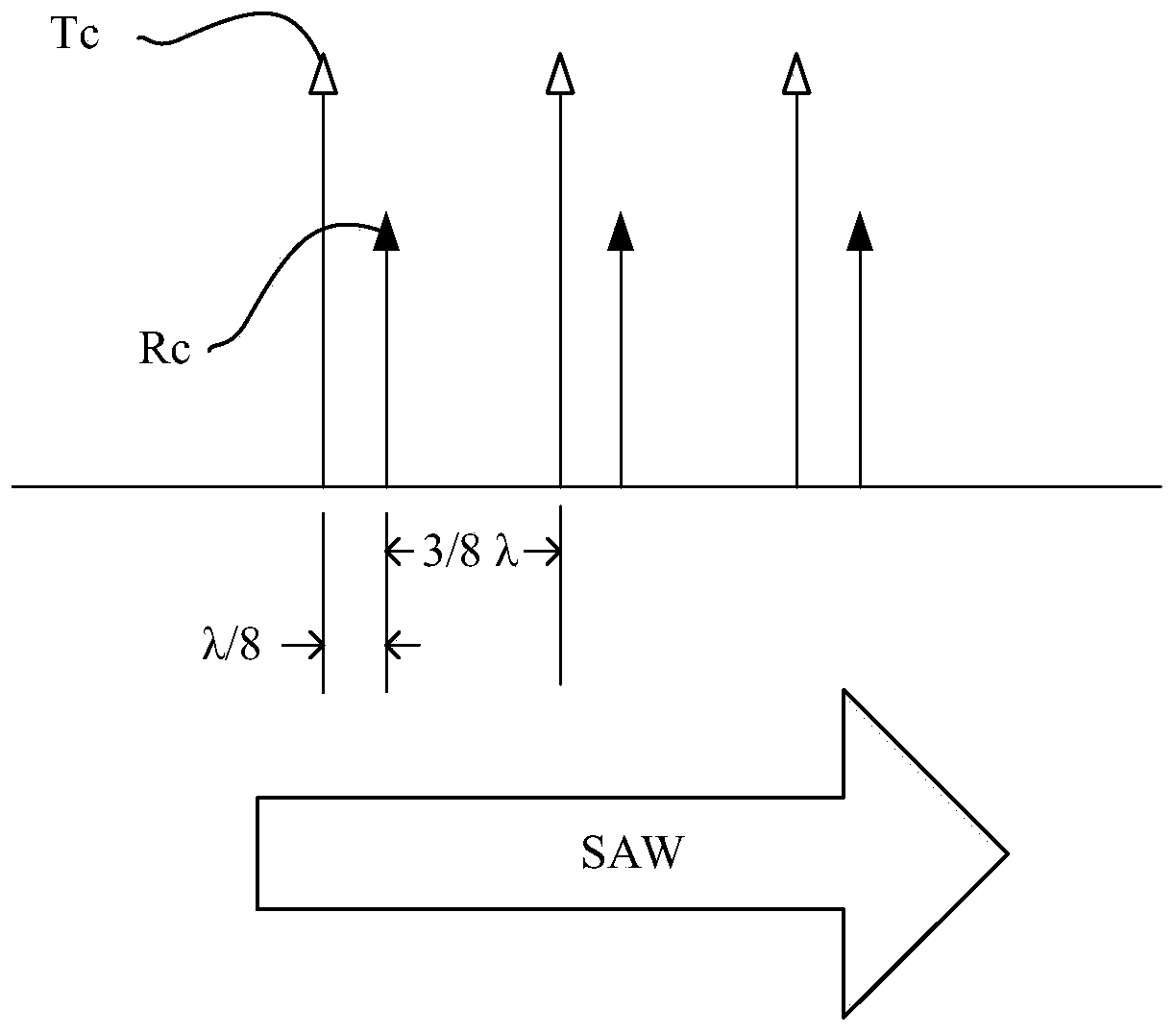

[0045] In various examples, the present disclosure describes a surface acoustic wave (SAW) device in which at least one interdigital transducer (IDT) generates a SAW that propagates in only one direction (ie, unidirectional). With reasonable IDT electrode design, the direction of wave propagation can be controlled. The disclosed example SAW devices can address one or more disadvantages of devices using conventional single-phase unidirectional transducers (SPUDTs) (e.g., natural SPUDTs (natural SPUDTs, NSPUDTs), floating electrode unidirectional Converter (floating electrode unidirectional transducer, FEUDT), film thickness difference type SPUDT, etc.).

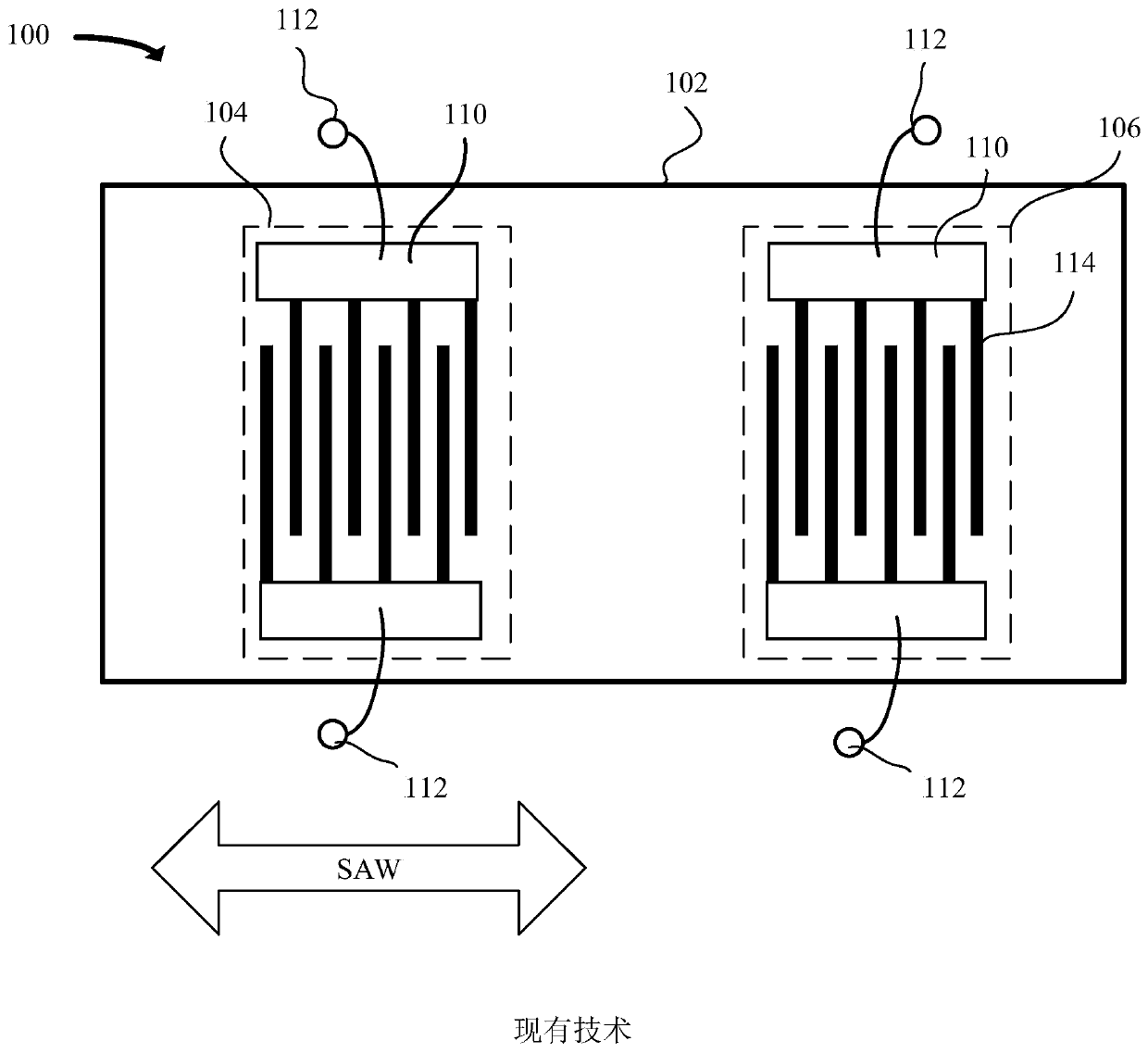

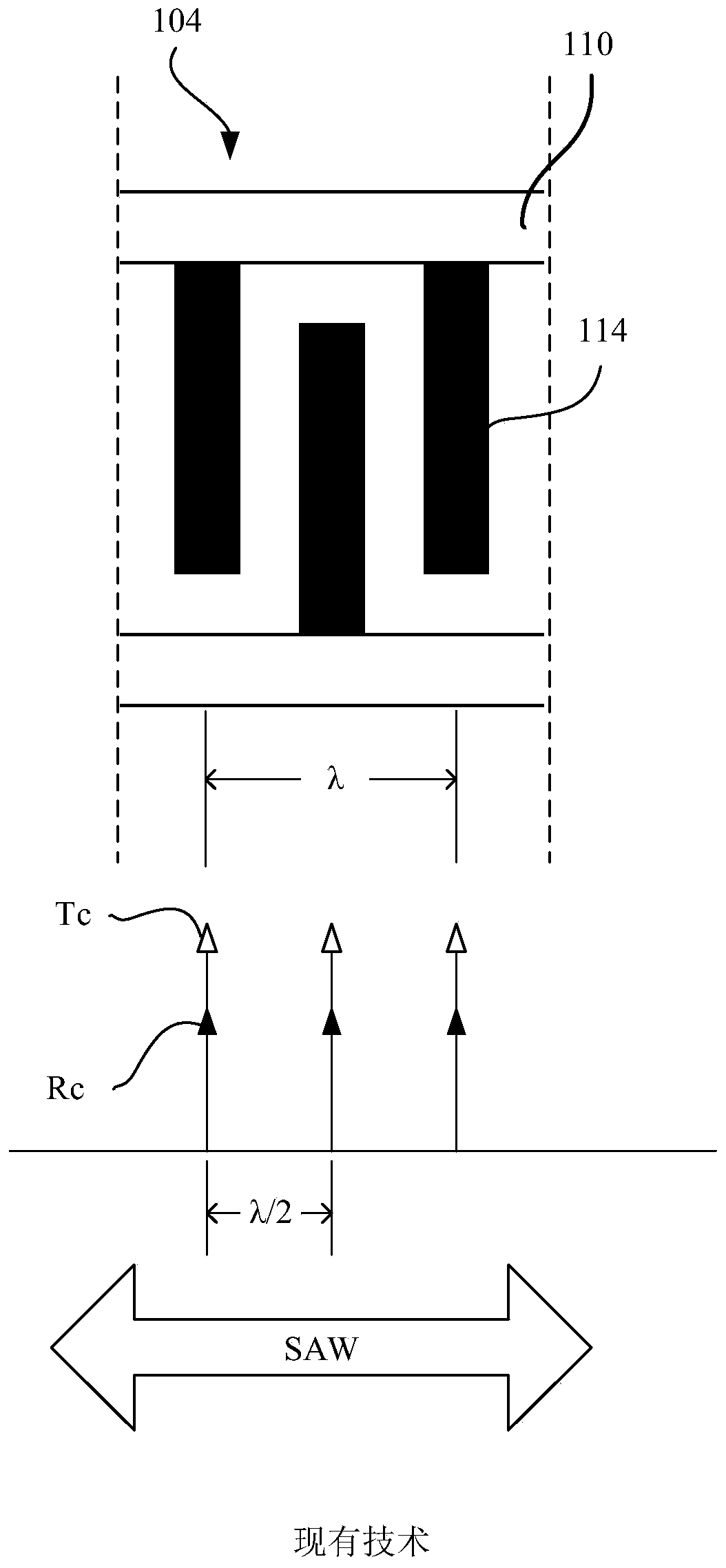

[0046] figure 1 An example conventional SAW device 100, in this case a transversal filter, is shown in . The dimensions of some features are exaggerated for illustrative purposes. For the purpose of illustration, the following description takes a transversal SAW filter as an example. However, the techniques described herei...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap