A metal orthopedic mold

A technology of metal parts and molds, applied in the field of metal parts orthopedic molds, can solve the problems of copper strip scratches, copper strip deformation, affecting product quality, etc., to save costs, increase workload, and reduce workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

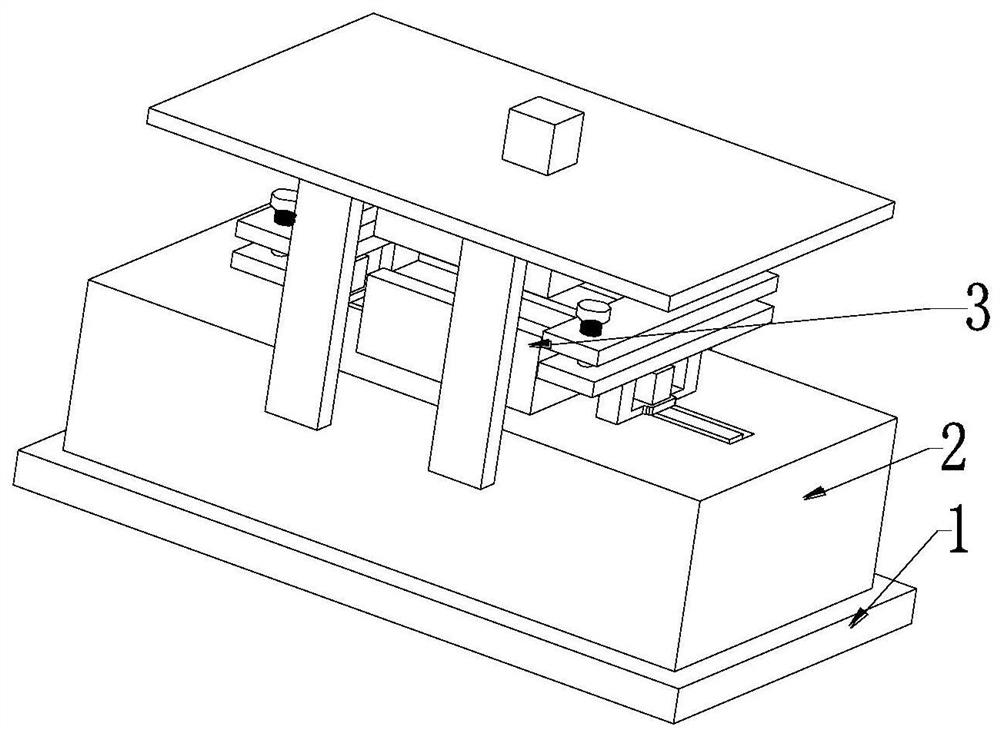

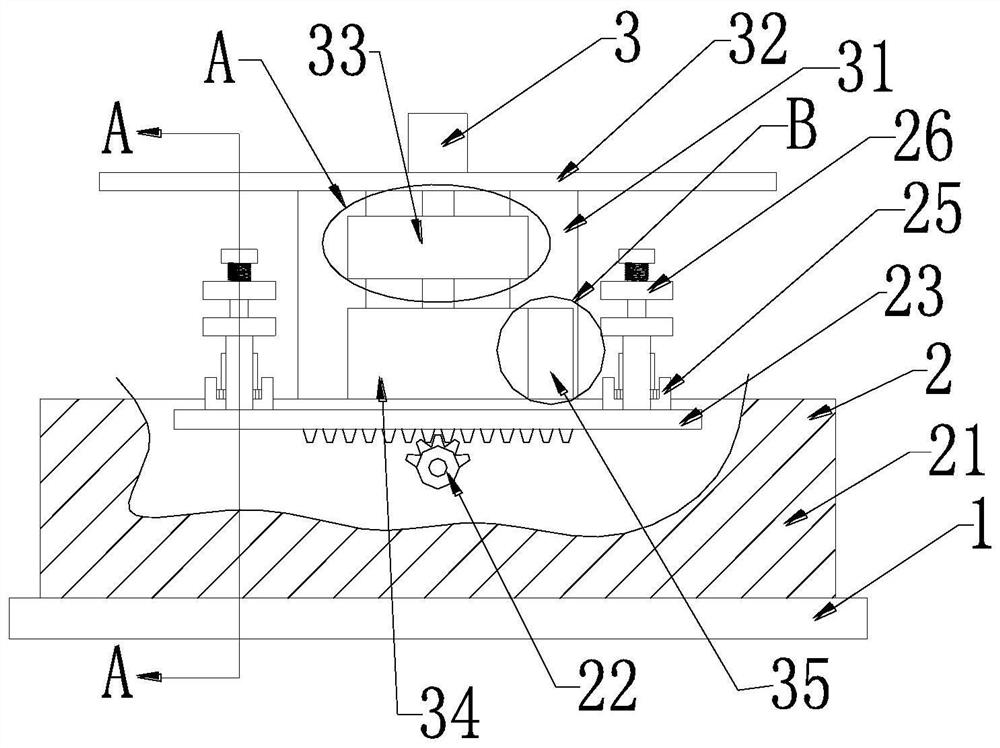

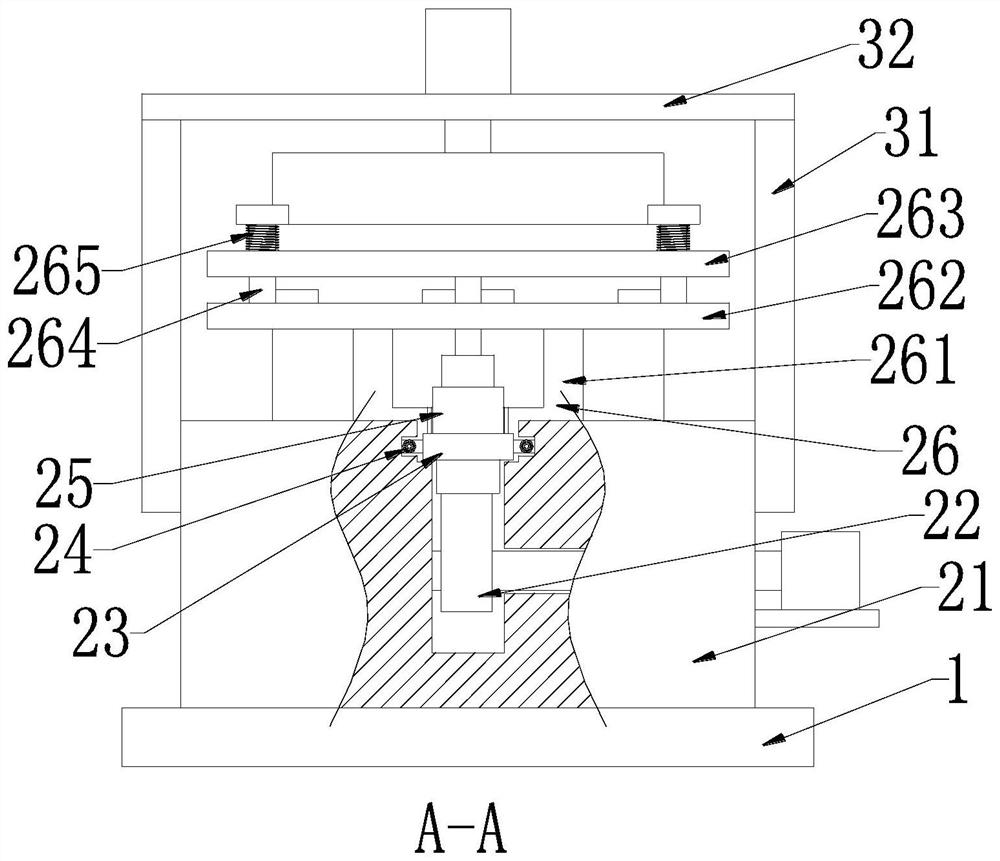

[0024] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0025] An orthopedic mold for metal parts, comprising a mounting frame 1, a conveying kit 2 and a shaping kit 3, the mounting frame 1 is provided with a conveying kit 2, and the upper end of the conveying kit 2 is provided with a shaping kit 3, wherein:

[0026] The conveying kit 2 includes a drive box 21, a No. 1 motor, a drive half gear 22, a traction rack 23, a return spring 24, a traction splint 25 and a pull frame 26, and the drive box 21 is installed on the mounting frame 1 by welding , No. 1 motor is installed on the motor base of drive box 21, and drive half gear 22 is installed on the output shaft of No. 1 motor, and the traction rack 23 that cooperates with each other is arranged on the upper end of drive half gear 22, and traction rack 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com