Clamping device for car body plate processing of car

A technology of automobile body and clamping device, which is applied in the direction of workpiece clamping device, workbench, manufacturing tools, etc., can solve the problems of limiting the scope of application, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

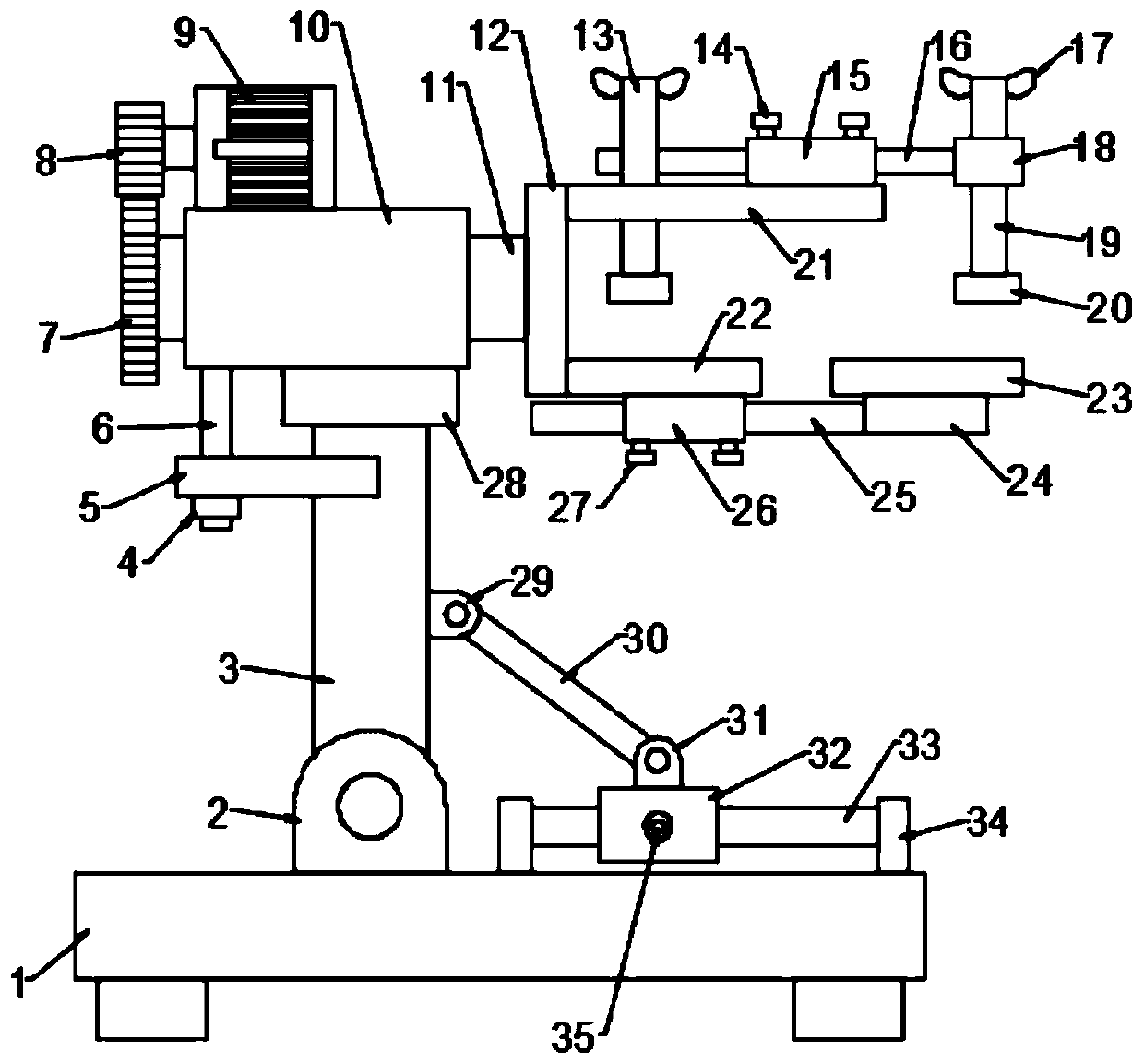

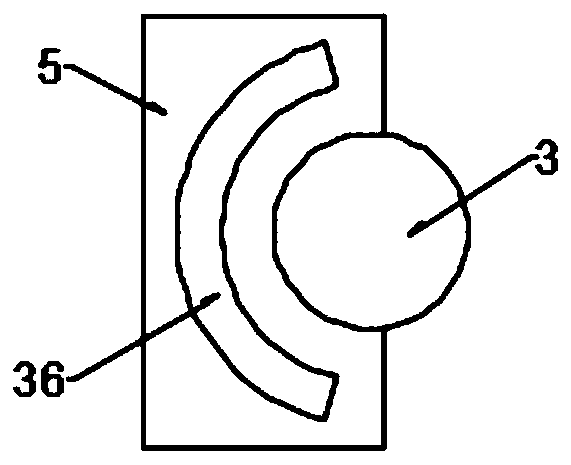

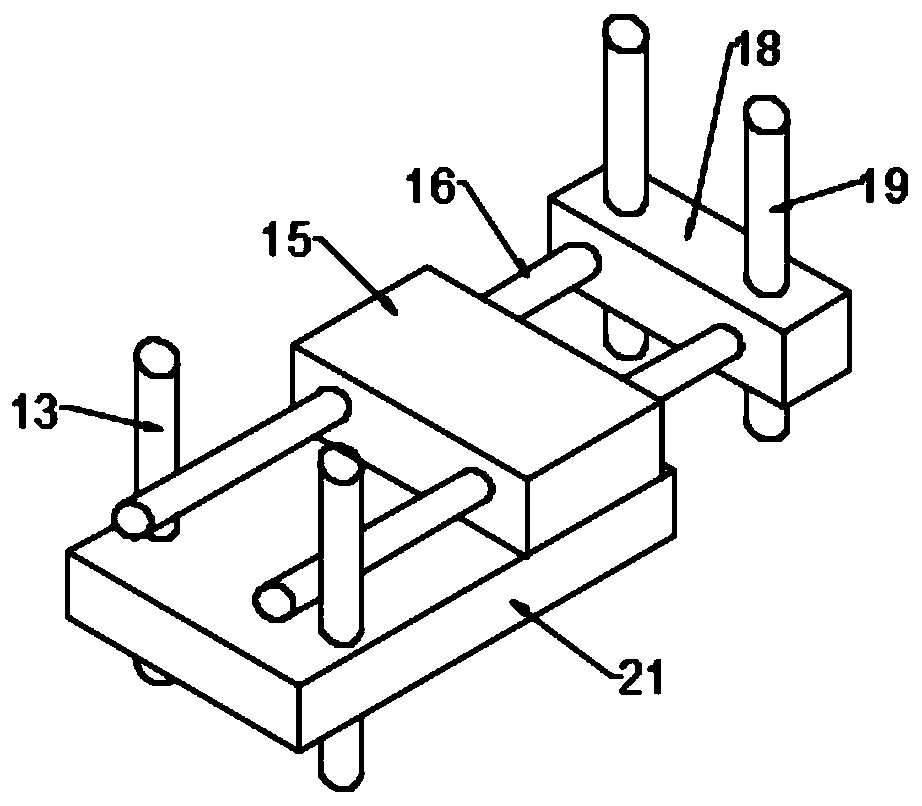

[0029] see Figure 1-3 , in an embodiment of the present invention, a clamping device for processing automobile body panels, including a base plate 1, a first support 2 is installed on the base plate 1, a bearing seat 28 is connected to the top of the first support 2, and the bearing The axle sleeve 10 is installed on the seat 28, and the bearing on the axle sleeve 10 is connected with the rotating shaft 11, and the rotating plate 12 is fixed on the rotating shaft 11, and the horizontal plate 21 and the first supporting plate 22 are fixed on the rotating plate 12, and the horizontal plate 21 and the first The supporting plate 22 is provided with an adjustable clamp assembly, the column 3 is provided with a locking assembly for locking the bushing 10, and the bottom plate 1 is provided with an adjustment assembly for adjusting the angle of the column 3; during use, the adjustable clamp assembly can clamp To support different sizes of automobile body panels, through the cooperat...

Embodiment 2

[0042] see Figure 4 , in the embodiment of the present invention, a kind of clamping device of automobile body panel processing is different from embodiment 1 in that a bracket 38 is fixed on the side of the column 3, and a storage tank 37 is installed on the bracket 38; , the tool can be placed in the storage tank 37, which is convenient and quick to take and place, and then facilitates processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com