Scatter-point recombination mold for one-time molding of spherical plastic net

A plastic net and spherical technology, which is applied in the field of scattered-point recombination molds for one-time molding of spherical plastic nets, can solve the problems of low production efficiency of spherical plastic nets and increased molding workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

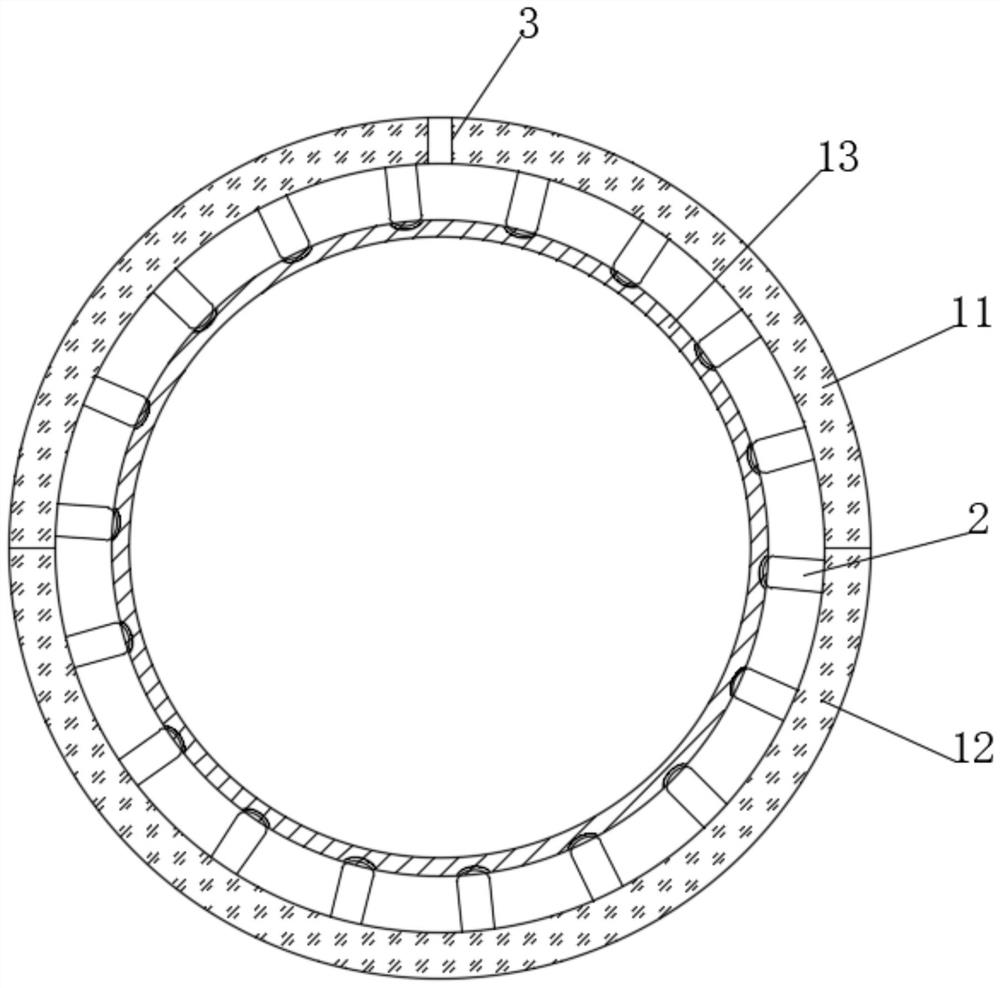

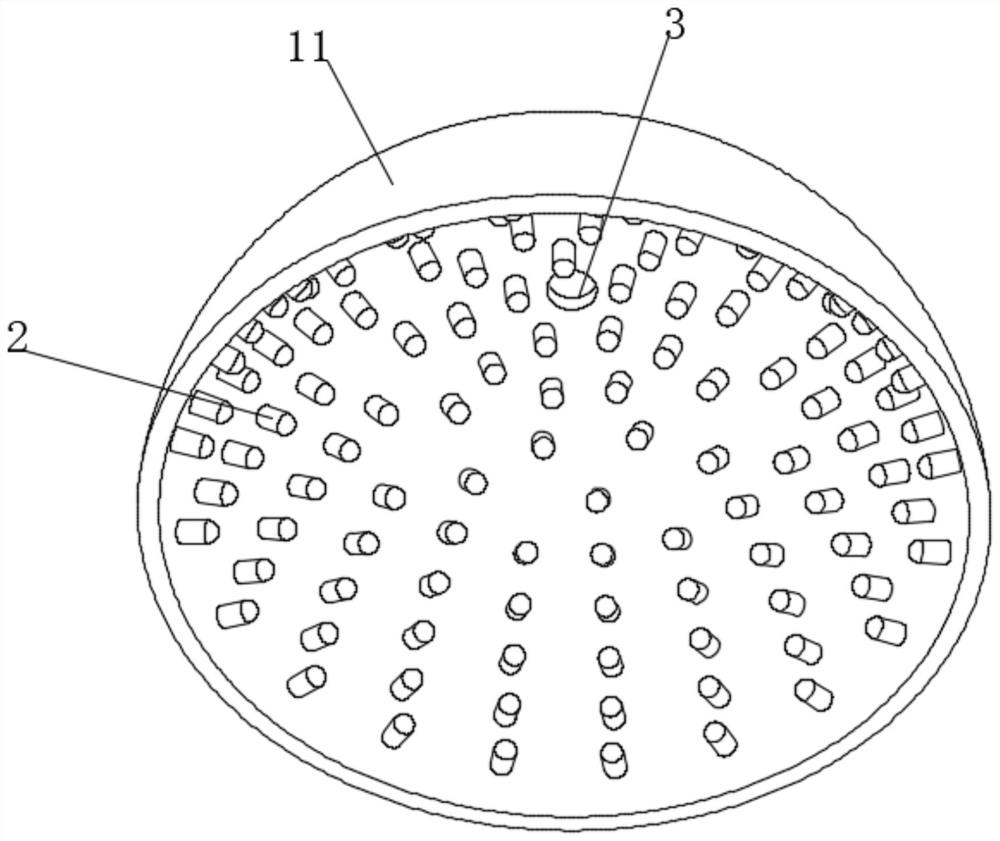

[0046] see Figure 1-2 , a kind of scatter-point recombination mold for one-time molding of a spherical plastic net, comprising an upper mold 11, a lower mold 12 and an inner scatter-point ball mold 13, the upper mold 11 is located above the lower mold 12, and the inner scatter-point ball mold 13 is located at the upper mold 11 On the inner side of the lower mold 12, the upper mold 11 and the inner wall of the lower mold 12 are fixedly connected with a plurality of evenly distributed mold hole columns 2, and the plurality of mold hole columns 2 are all matched with the inner scattered ball mold 13.

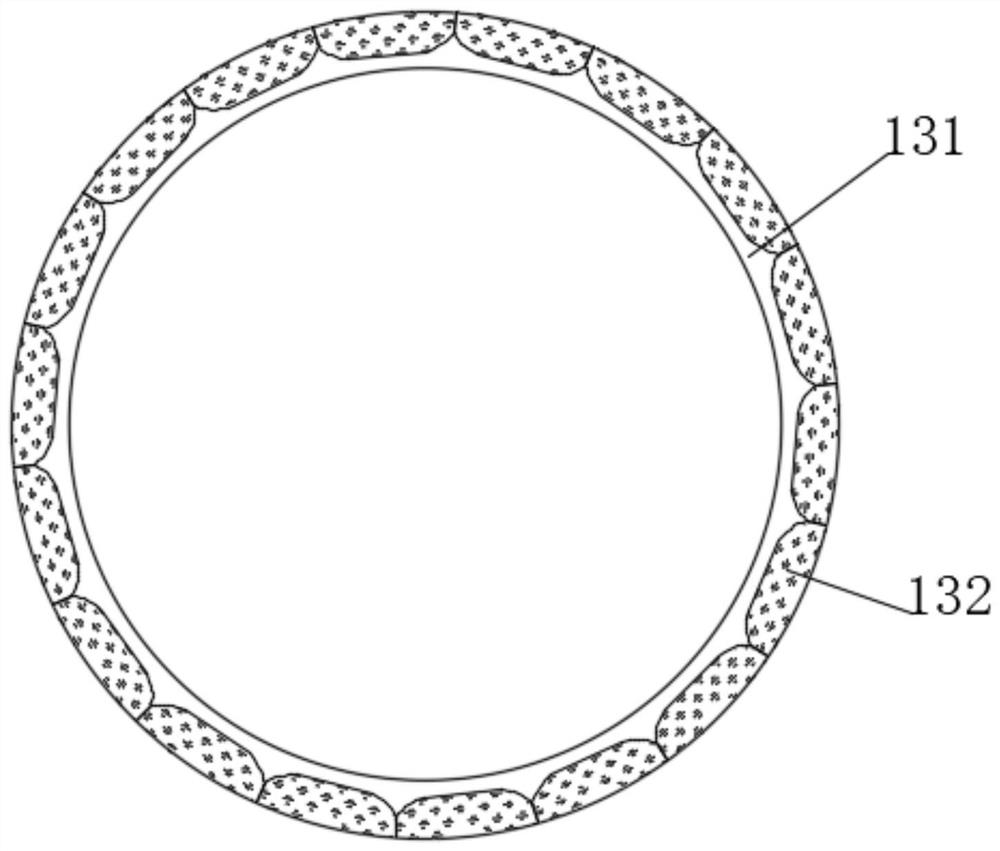

[0047] see image 3 , the inner scattered point ball mold 13 includes the expansion and contraction mold skeleton 131 located on the inner side and a plurality of scattered point mold pieces 132 located on the outer side, please refer to Figure 4-5 , the scatter-point die sheet 132 outer surface is excavated with magnetic suction groove 7, and the maximum distance at the 7 notch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com