Industrial sponge preparation automatic winding and cutting processing machinery

A technology for processing machinery and sponges, which is applied in the field of automatic rolling and cutting processing machinery for industrial sponge preparation, and can solve problems such as sponge wrinkles, burrs, and impact on use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

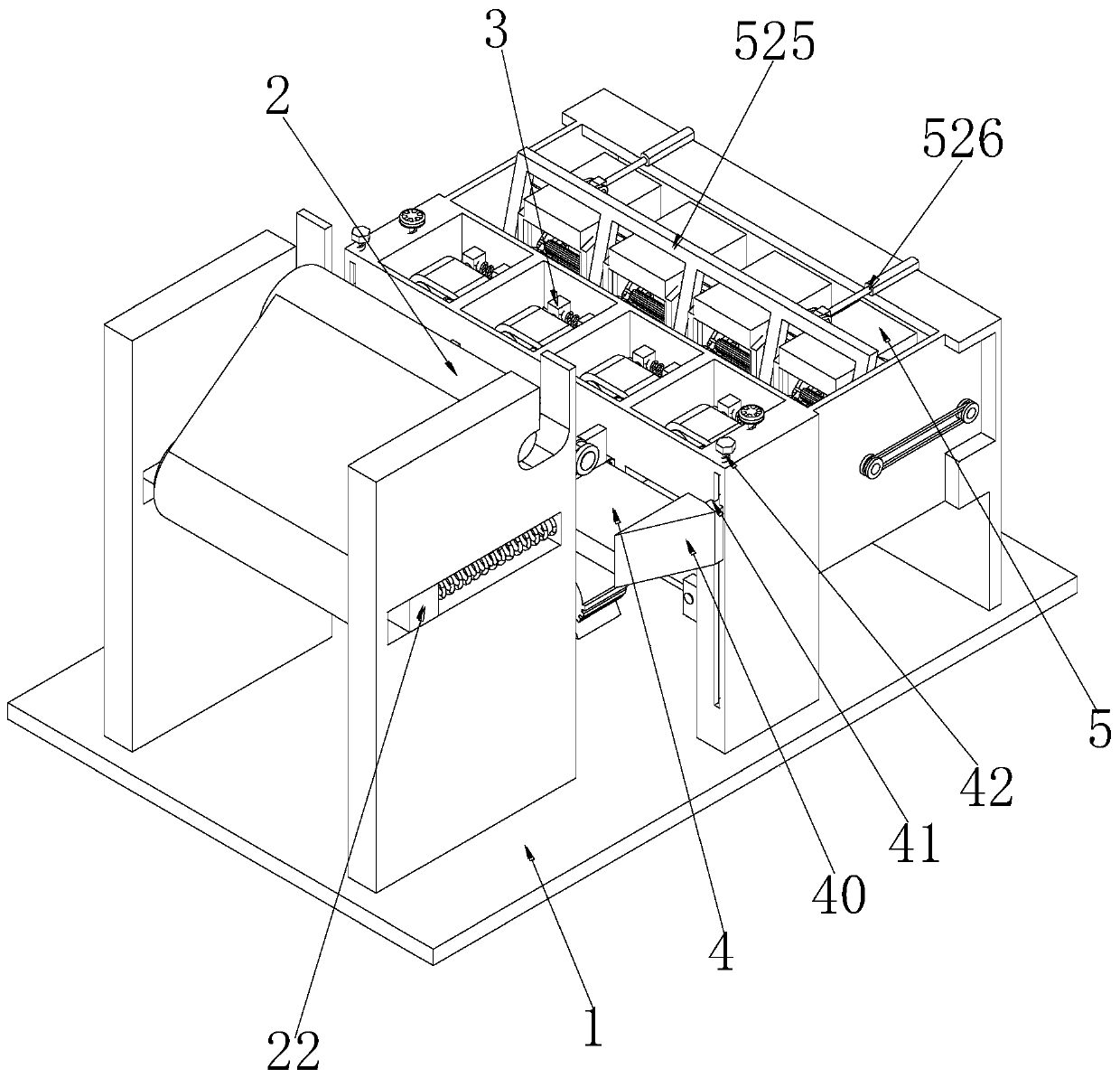

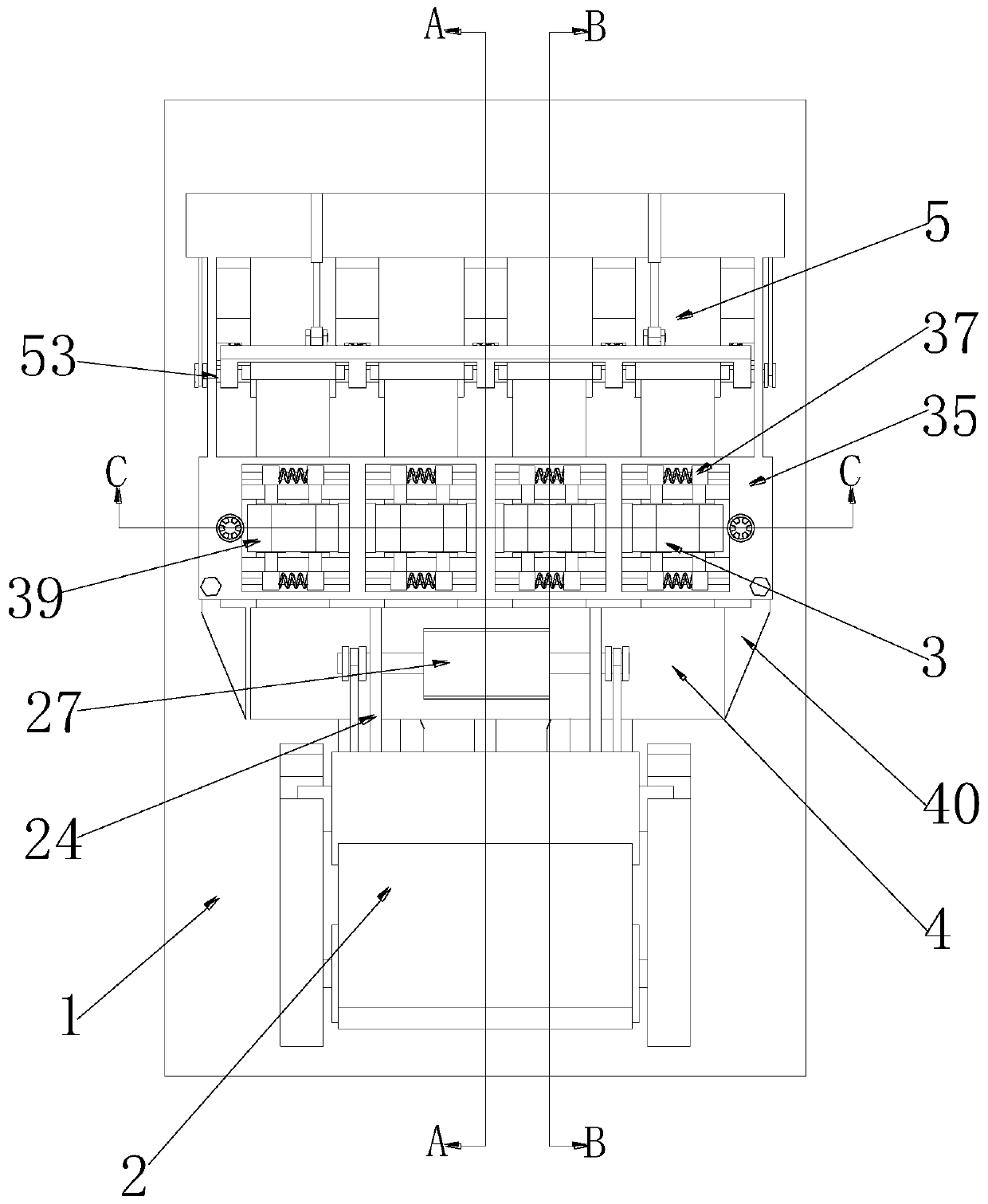

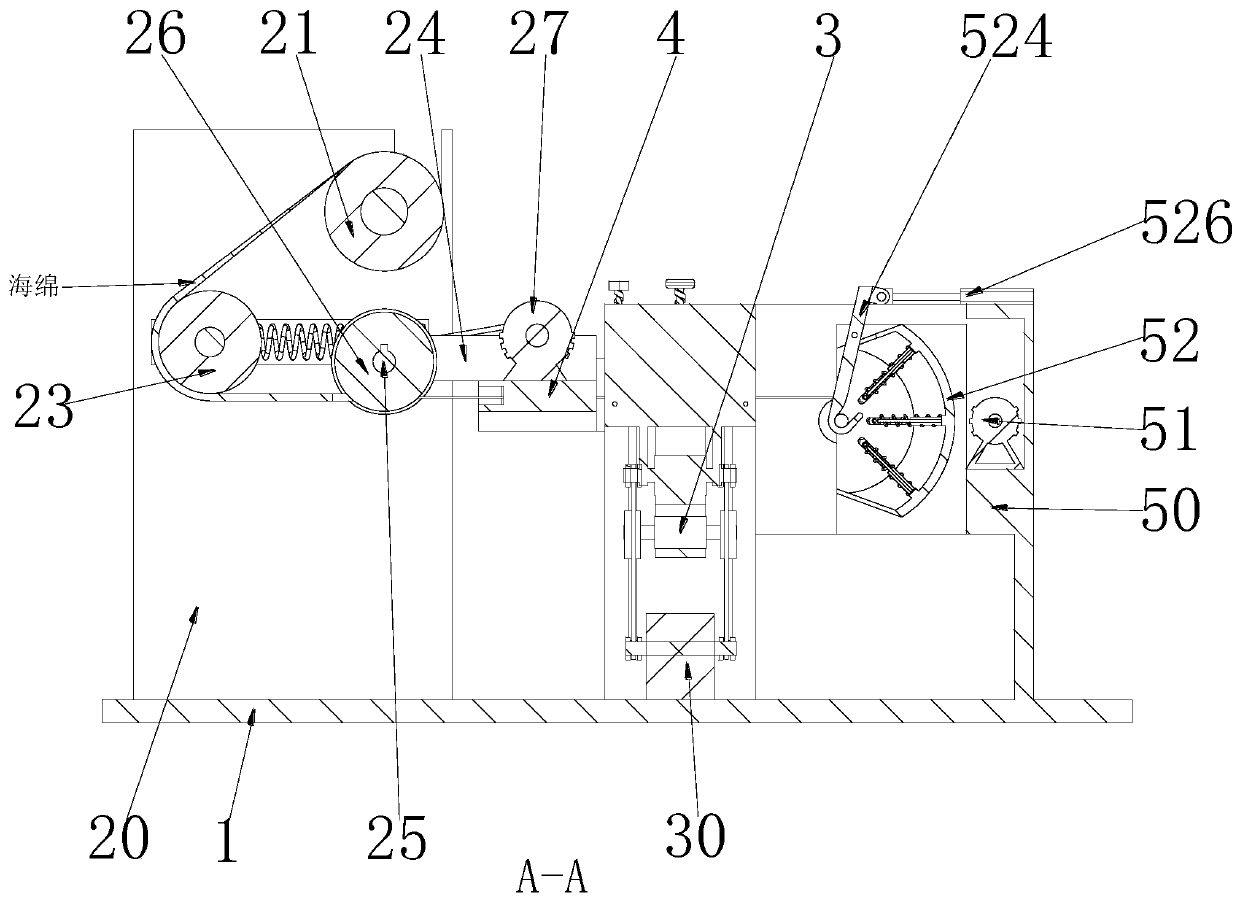

[0026] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0027] An automatic rolling and cutting processing machine for industrial sponge preparation, including a base 1, a cutting unit 2, a sorting unit 3, a direction adjustment unit 4 and a winding unit 5, a cutting unit 2 is arranged on the left side of the upper surface of the base 1, and the cutting unit 2 and the sorting unit A steering unit 4 is arranged between the units 3, and a winding unit 5 is arranged on the right side of the sorting unit 3; wherein:

[0028] The cutting unit 2 includes a cutting vertical plate 20, a sponge roller 21, an adjustment slider 22, an adjustment roller 23, a cutting pole 24, a cutting shaft 25, a cutting saw blade 26 and a cutting motor 27, and the left side of the upper surface of the base 1 A cutting vertical bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com