A high-efficiency automatic film blowing device to prevent electrostatic interference

A technology of electrostatic interference and membrane device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

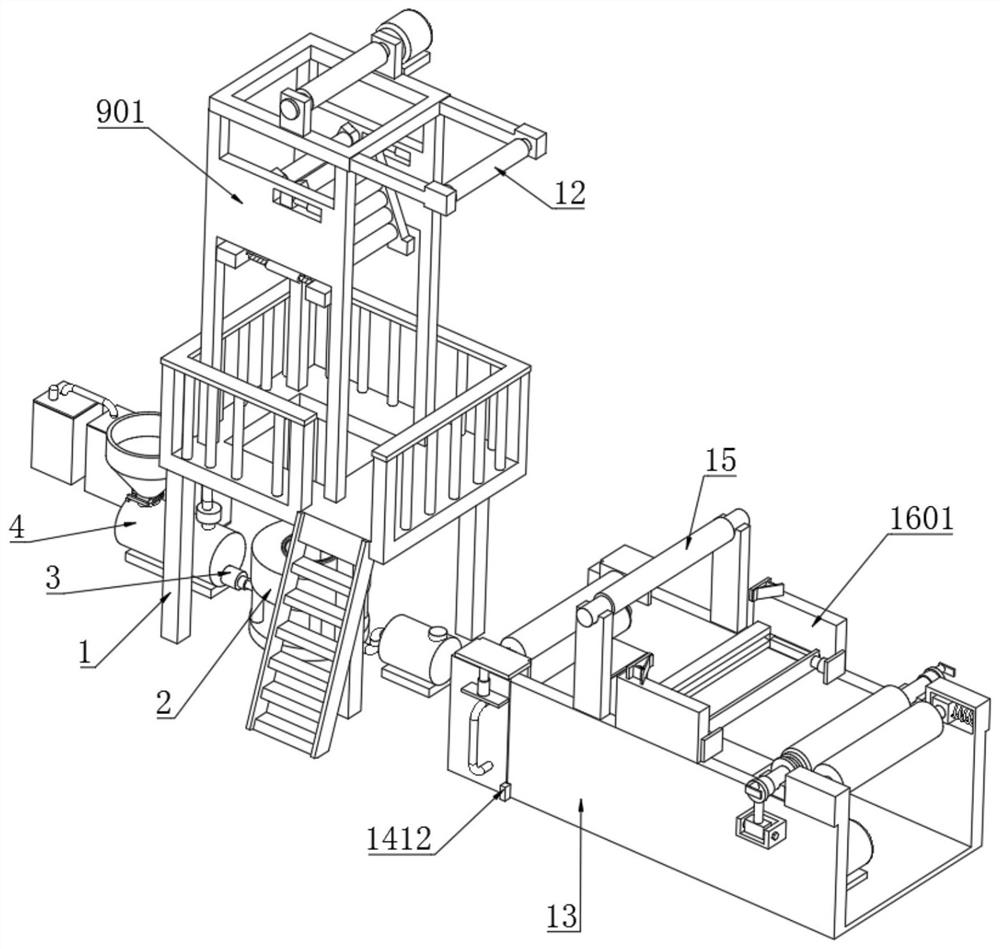

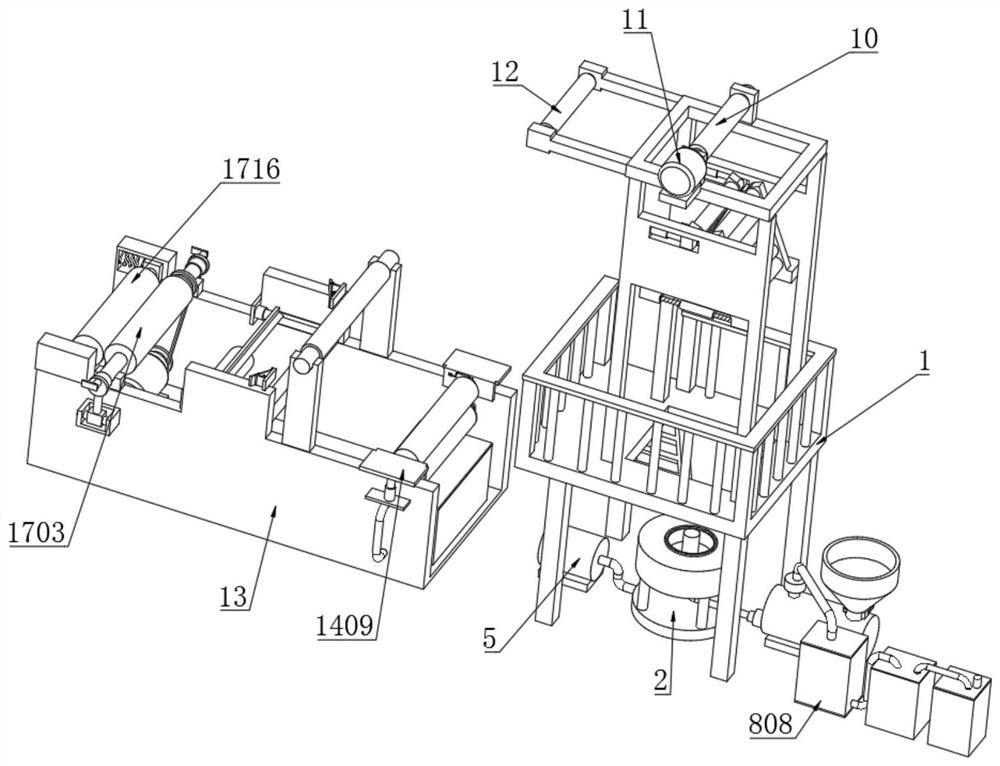

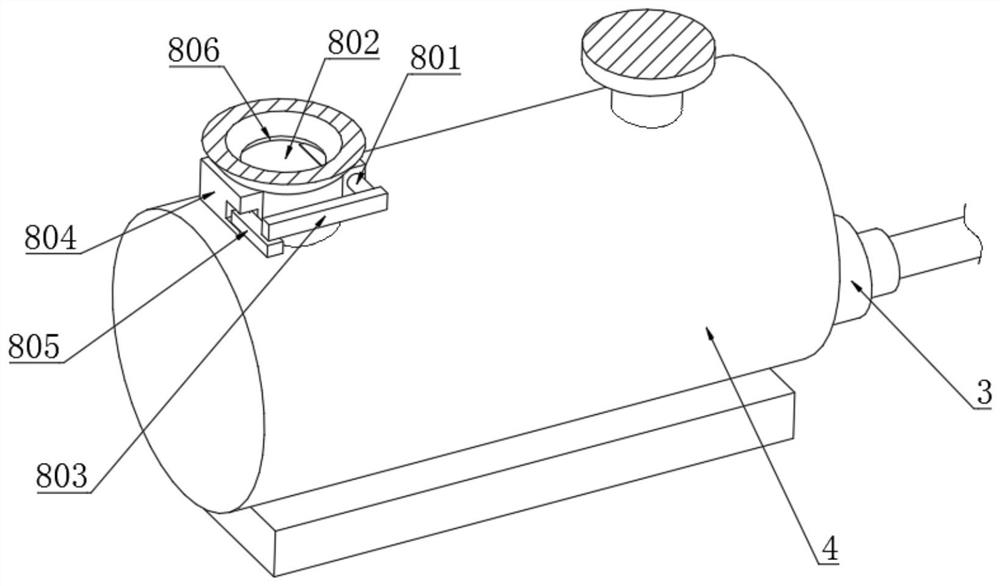

[0054] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a high-efficiency automatic film blowing device for preventing electrostatic interference, comprising a frame 1, a film blowing die 2 is fixedly installed in the middle of the bottom end of the frame 1, and the melted plastic is blown by a blower 5 Blowing into plastic film, one end of the top of the film blowing die 2 is fixedly connected with a squeeze pump 3, and one end of the squeeze pump 3 is fixedly installed with a melt tank 4 to melt the raw material, and then use the squeeze pump 3 to transport to Inside the film blowing die 2, the blower 5 is fixedly connected to the bottom end of the blowing film die 2 away from the squeeze pump 3, and the injection pipe 6 is fixedly connected to the top end of the melting tank body 4, and the top of the injection pipe 6 A storage hopper 7 is fixedly installed, and an exhaust gas removal mechanism 8 is installed on the top of the mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com