Roof truss hoisting method

A hoisting method and roof truss technology, which are applied in the direction of construction, building structure, and building material processing, can solve problems such as low safety, low labor efficiency, and unstable roof trusses, and achieve high safety, increased stability, and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

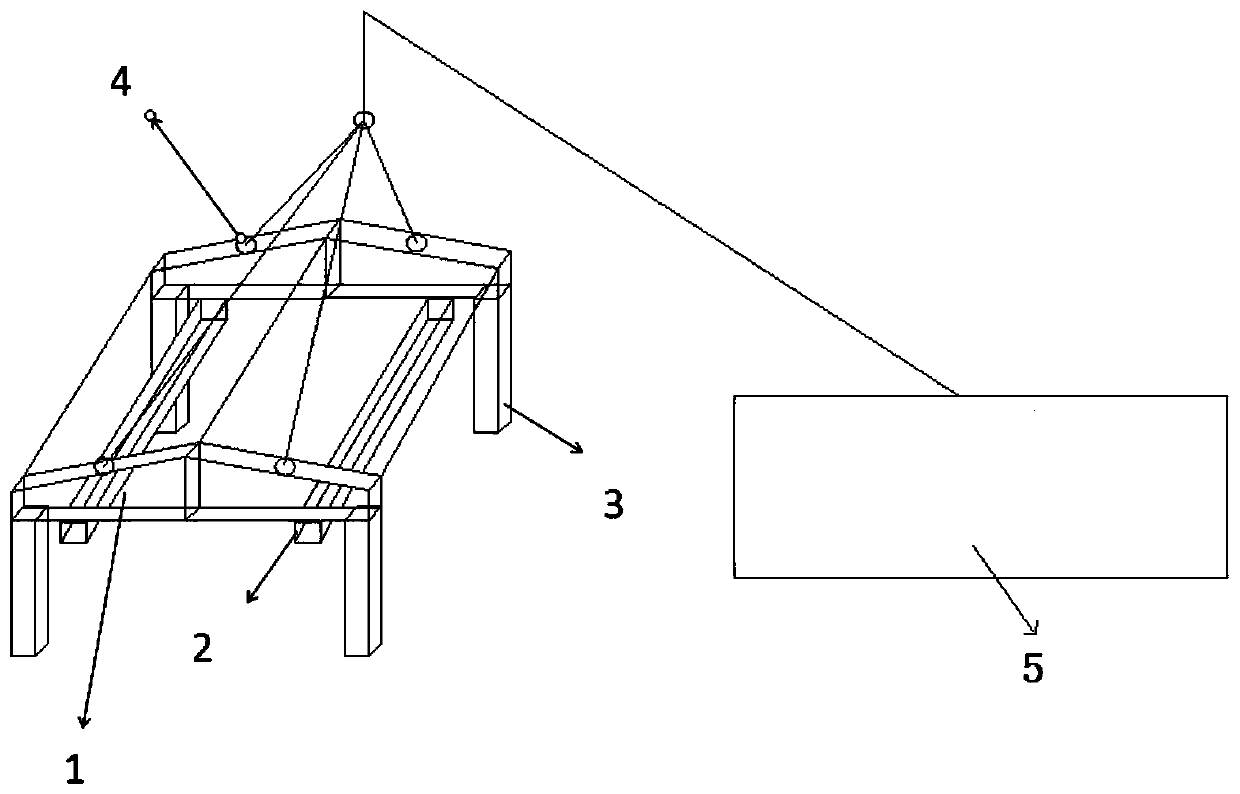

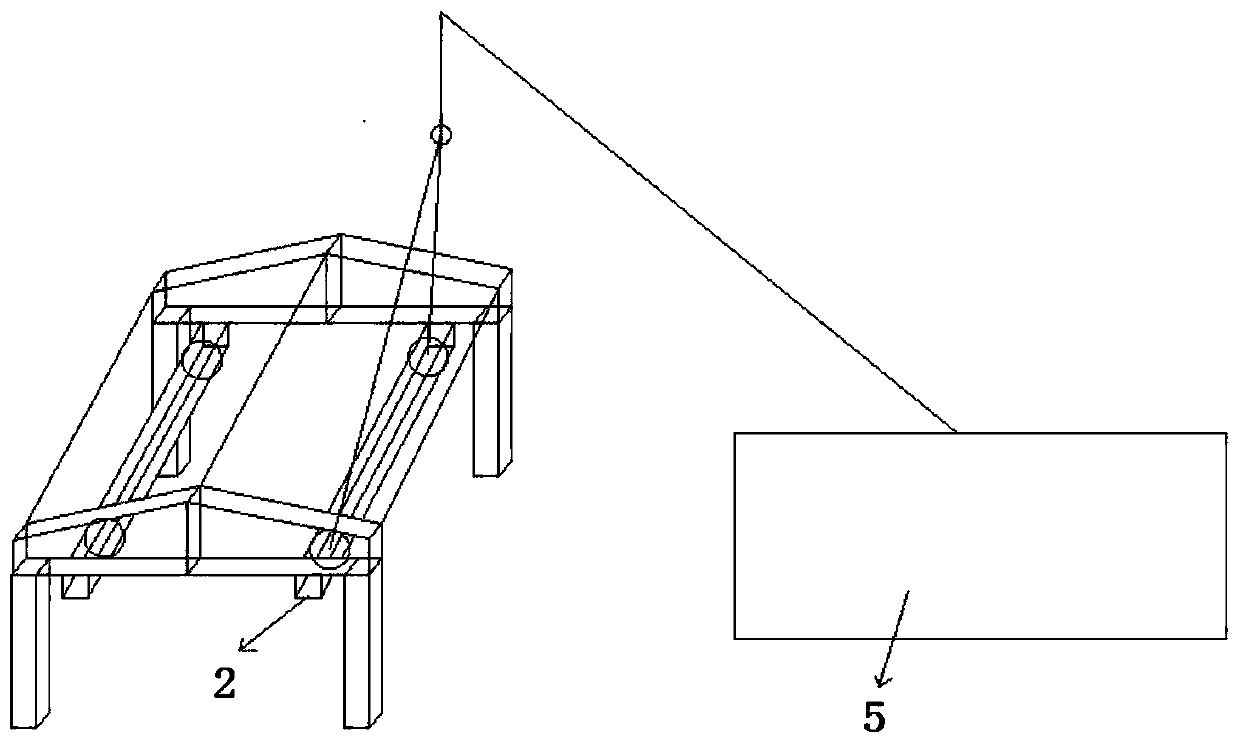

[0015] see figure 1 and figure 2 , a roof truss hoisting method, according to the following steps:

[0016] 1) First assemble n roof trusses in the site to form a roof truss system 1, where n≥2.

[0017] 2) Weld at least two supporting poles 2 at the bottom of the lower chord of the roof truss system 1 along the length direction of the roof truss system 1 .

[0018] 3) Select four lifting points 4 on the upper chord of the roof truss system 1, and then use the crane 5 to hoist the roof truss system 1 to the position of the embedded plate on the top of the prefabricated column 3 to complete the installation.

[0019] 4) Disassemble the roof truss system 1 and the supporting pole 2, and use the crane 5 to lift the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com