Extra-high-voltage direct current wall bushing high-voltage test supporting platform and using method

An ultra-high voltage DC, wall bushing technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of poor safety, labor consumption, partial discharge power, etc., and achieve stable force, easy installation, and heavy weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

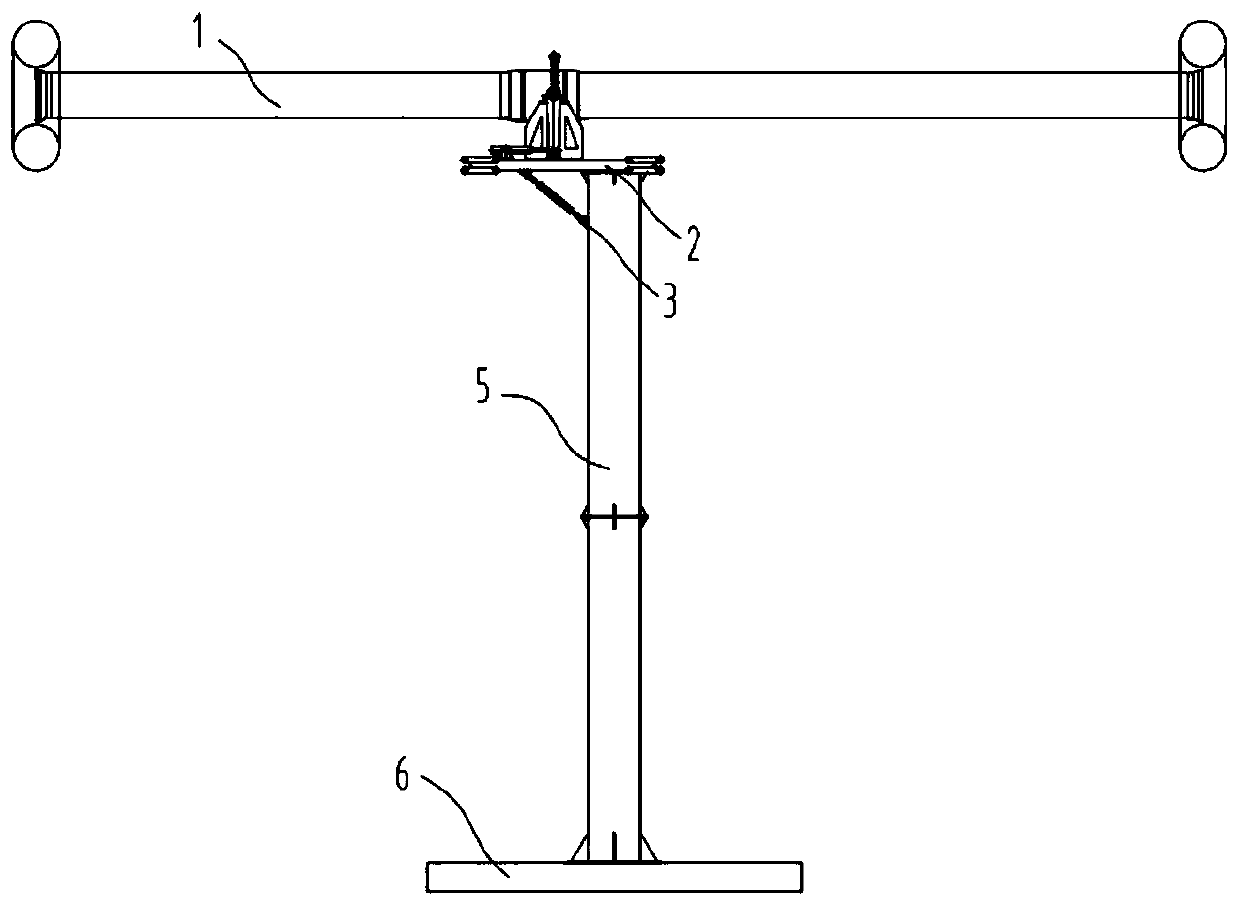

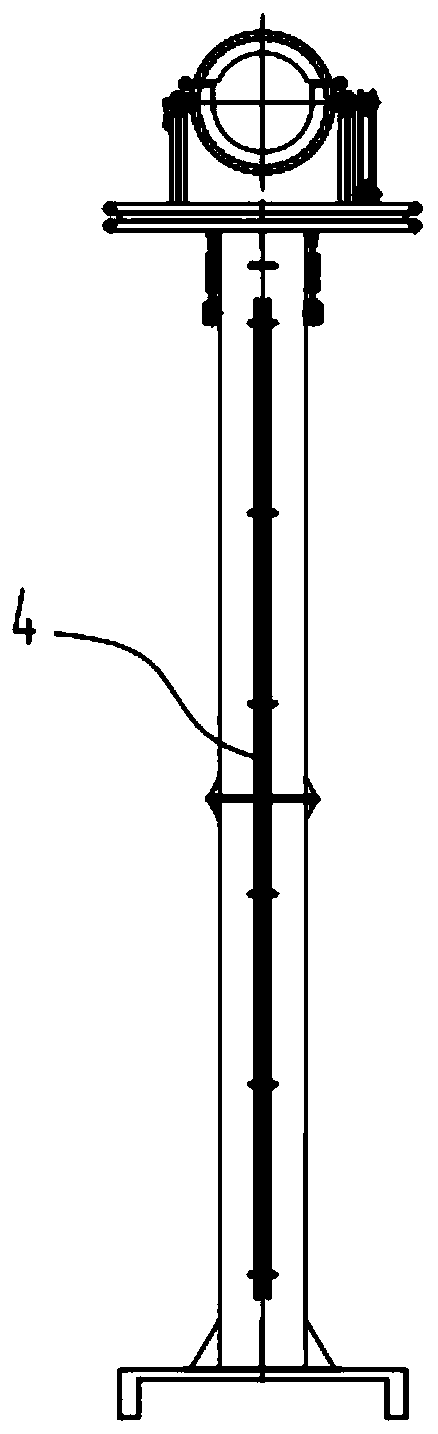

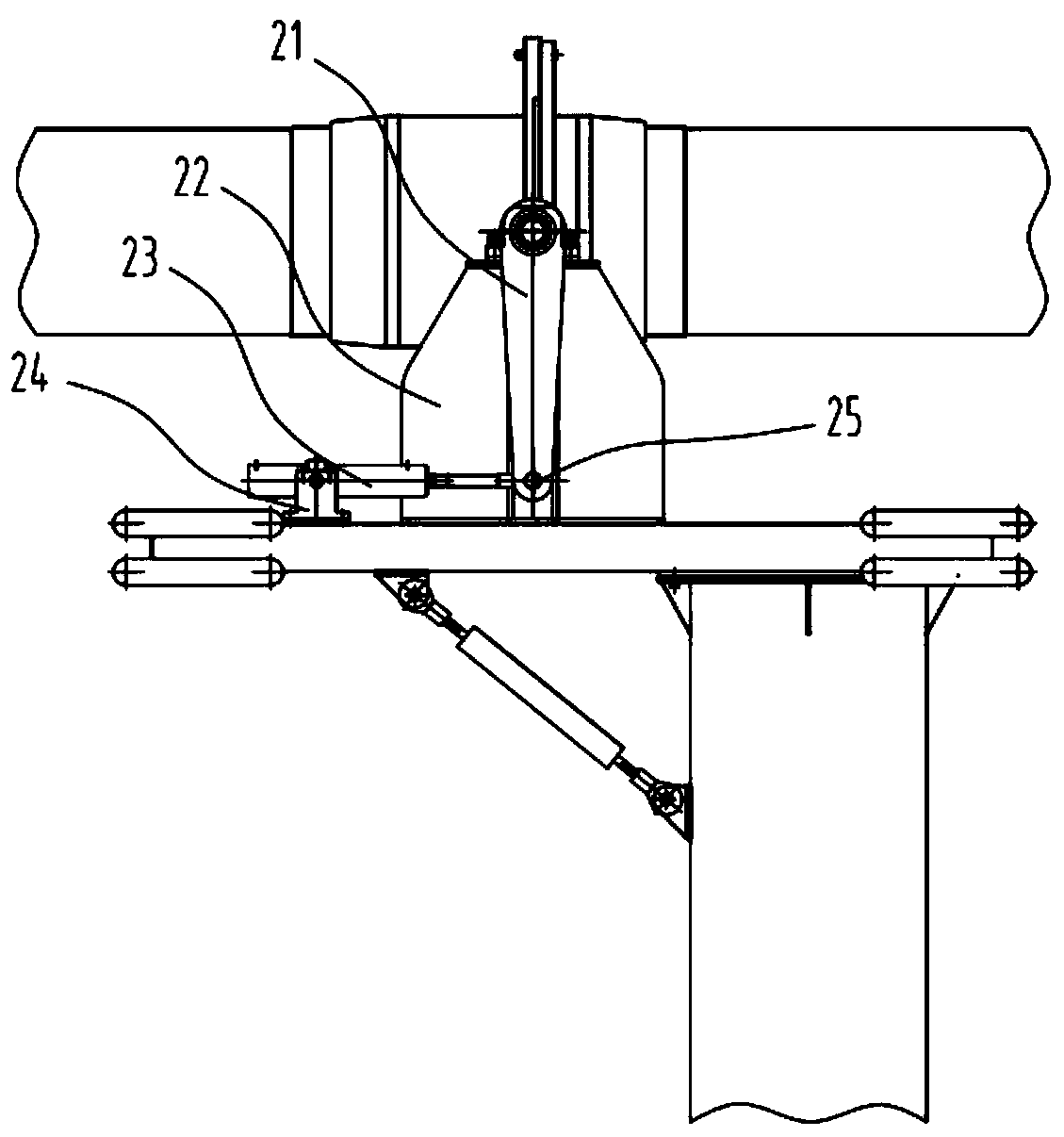

[0035] see Figure 1 to Figure 5 , a high-voltage test support platform for UHV DC wall bushing 1, which includes a support cylinder 5, a main platform 2, a bushing support 22, a mounting flange, a driving rod 21, and a power part. The support cylinder 5 is connected and installed through the upper support cylinder 5 and the lower support cylinder 5, the lower end of the support cylinder 5 is fixed on the ground through the bracket 6, and the main platform 2 is fixedly installed on the upper end of the support cylinder 5, and the main platform 2 is fixed in the length direction. It has a first end surface and a second end surface, the distance from the first end surface to the fixed connection point is greater than the distance from the second end surface to the fixed connection point, so that the center of gravity of the main platform 2 is offset away from the axis of the support cylinder 5 , the main platform 2 of this embodiment is similar to a long plate shape, and the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com