Integrated aeration system

An aeration system and integrated technology, applied in the field of integrated aeration system, can solve the problems of heavy installation work, high installation cost, difficult maintenance, etc., and achieve the effect of saving installation time, reducing installation time and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

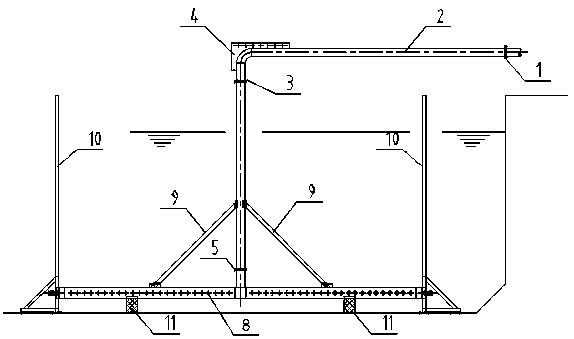

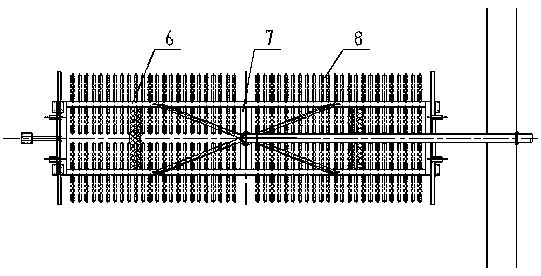

[0028] The vertical end of the intake main pipe 2 and the aeration branch pipe 6 are fixed by a diagonal brace 9, the purpose of which is to strengthen and fix the bottom aeration branch pipe 6 and increase the firmness and stability of the bottom aeration system.

Embodiment 2

[0030] A reinforcing plate 4 is installed at the bend of the intake main pipe 2, and a plurality of lifting holes are provided on the reinforcing plate 4, the purpose of which is to set multi-point lifting holes, which is convenient for lifting during installation and maintenance.

Embodiment 3

[0032] Limiting guide rails 10 perpendicular to the ends of the two aeration branch pipes 6 are also installed, the purpose of which is to limit the bottom aeration system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com