Lubricating oil for aluminum foil rolling as well as preparation method and application thereof

A lubricating oil and aluminum foil technology, which is applied in the field of lubricating oil, can solve the problems that the annealing cleanliness is greatly affected, high-lubricating rolling oil is not mentioned, and the oil film strength is low, so as to achieve good cleanliness in low-temperature annealing, improve application value, The effect of low kinematic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

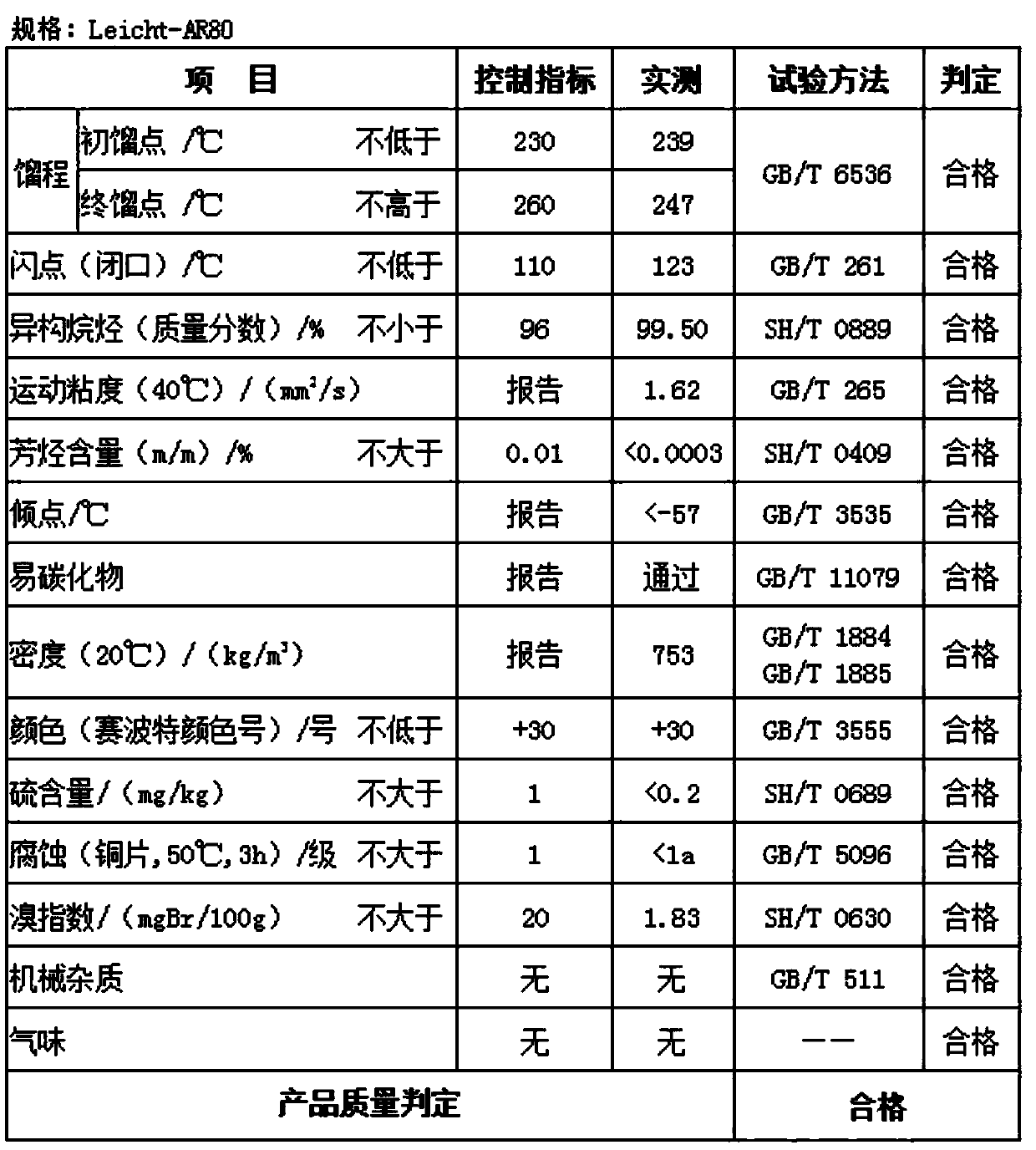

Image

Examples

Embodiment 1

[0035] A kind of aluminum foil rolling lubricating oil, its component and the mass percent of each component are:

[0036] Fischer-Tropsch synthetic light oil 91%, hexameric ricinoleic acid ester 5%, methyl oleate 3%, isooctyl acid phosphate ester octadecylamine 1%.

Embodiment 2

[0038] A kind of aluminum foil rolling lubricating oil, its component and the mass percent of each component are:

[0039] Fischer-Tropsch synthetic light oil 88.8%, tetrameric ricinoleate 6%, methyl oleate 4%, butyl isooctyl phosphate dodecylamine salt 1.2%.

Embodiment 3

[0041] A kind of aluminum foil rolling lubricating oil, its component and the mass percent of each component are:

[0042] Fischer-Tropsch synthetic light oil 93.2%, tetrameric ricinoleic acid ester 4%, ethyl oleate 2%, fatty alcohol ethoxylated phosphate ester 0.8%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap