An electric hot and cold water thermostatic mixing valve core

A constant temperature mixing valve, cold and hot water technology, applied in the field of valve core, can solve the problems of non-uniform valve core size, slow adjustment response, low adjustment accuracy, etc., to achieve accuracy, comfortable use, and fast adjustment speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

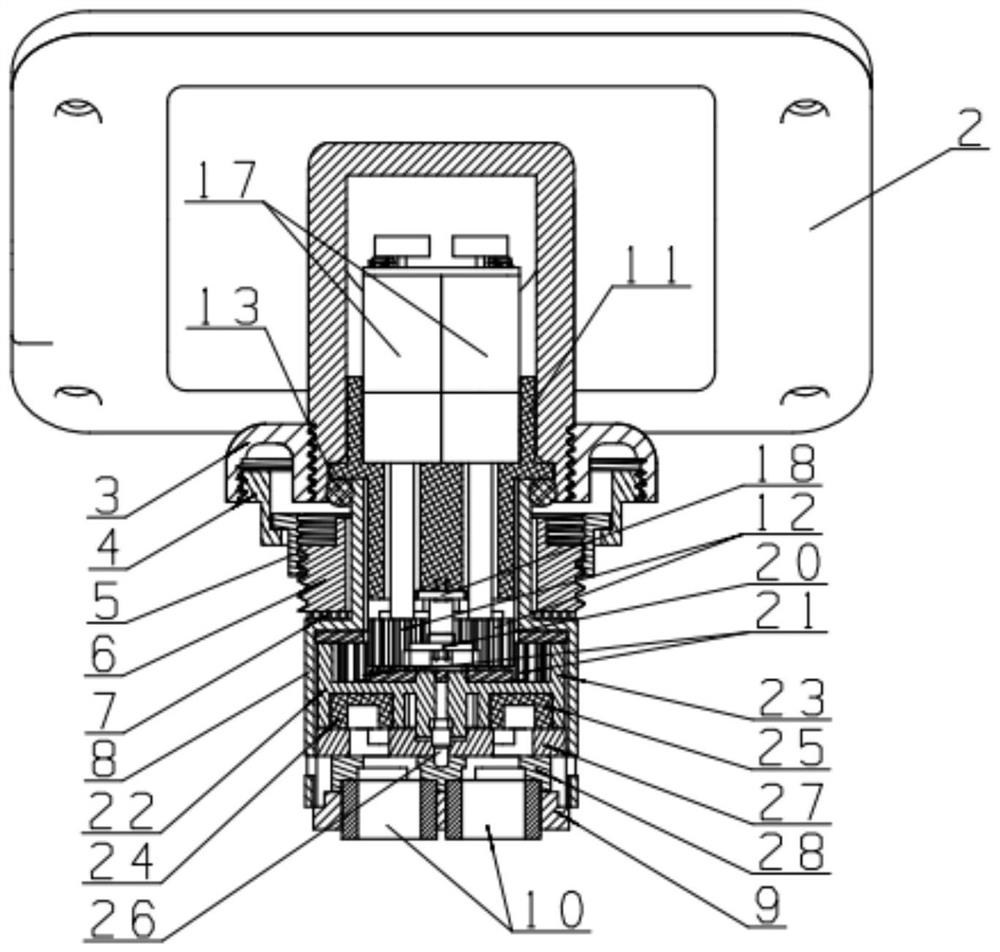

[0034] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

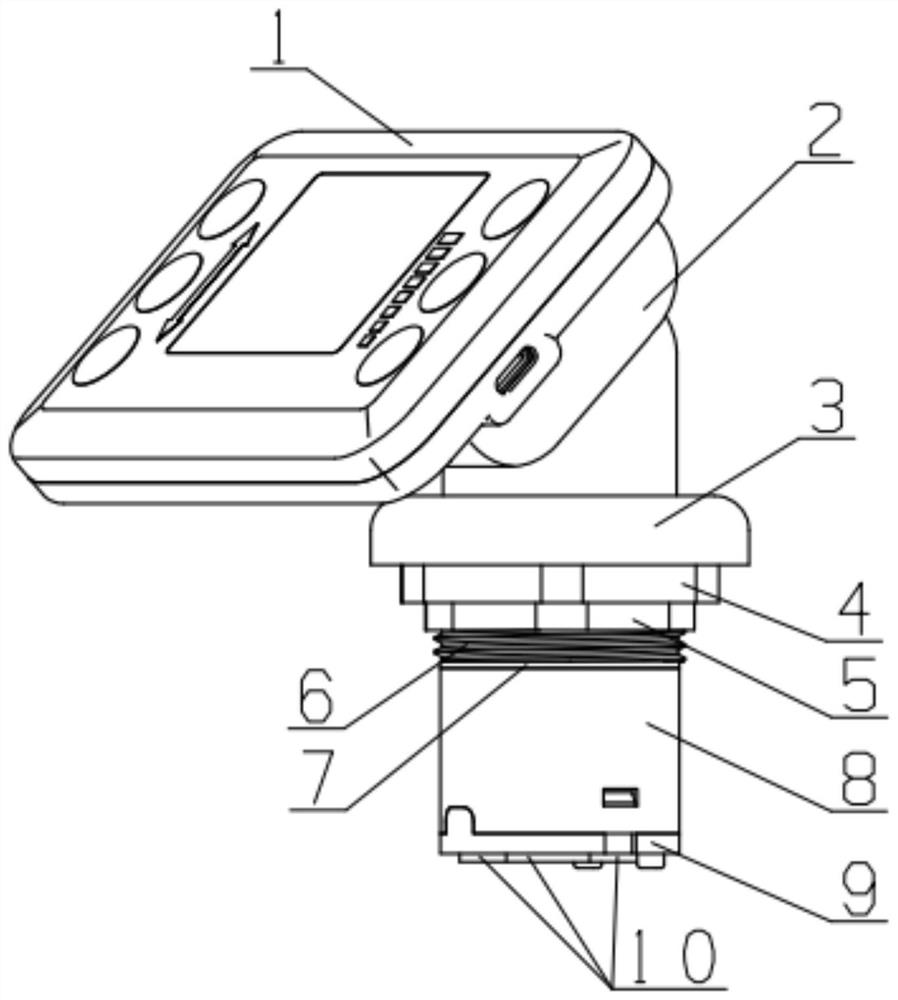

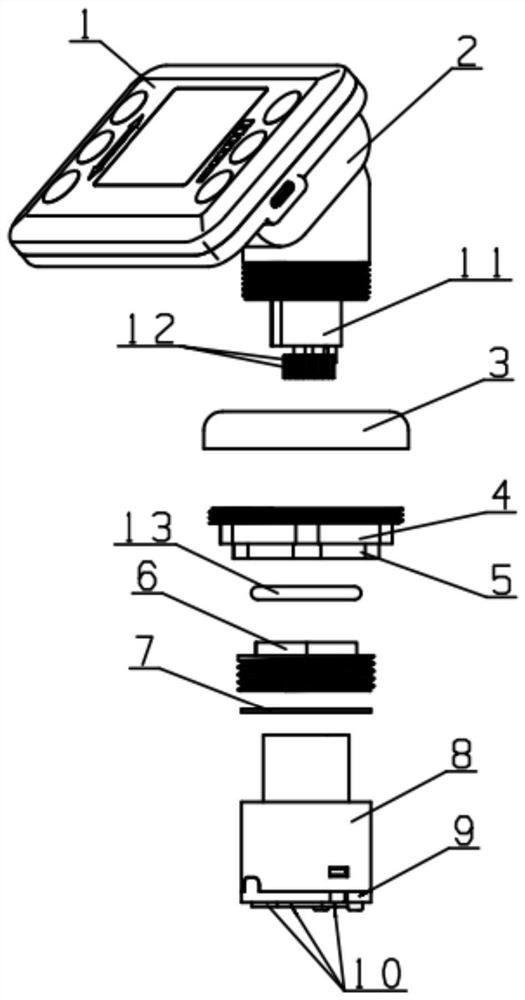

[0035] Such as figure 1 , figure 2 As shown, an electric cold and hot water constant temperature mixing valve core is divided into upper and lower parts, the upper part is the control and driving part, the lower part is the valve core part, and the two parts are plugged together and then tightly connected by a coil solid. The dimensions of the spool and the positions of the water inlet and outlet are exactly the same as those of the ordinary manual hot and cold water mixing valve. It can be used in the electric cold and hot water mixing valve, and can directly replace the ordinary manual hot and cold water mixing valve. The spool in the valve is put into the shell of the ordinary manual hot and cold water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com