Floor heating tube arranging and fixing device for housing construction

A technology of fixing device and floor heating pipe, applied in the application, household heating, household appliances and other directions, can solve the problems of not being able to play an auxiliary fixing, the elbow is not very ideal, etc., to improve the fixing effect, increase the practicability, and have a novel design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

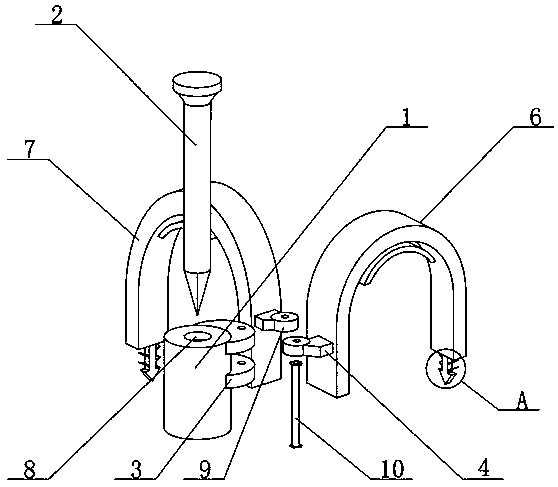

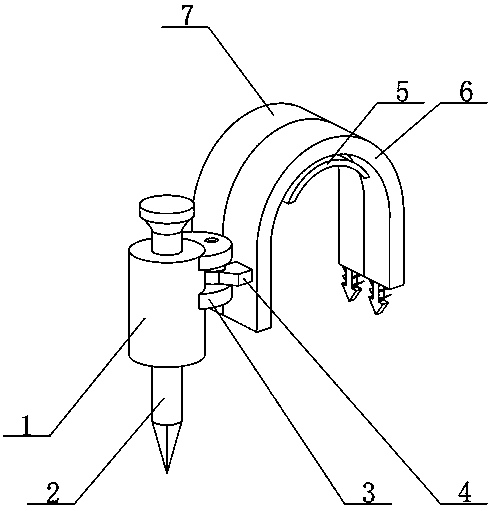

[0021] see Figure 1-6 , in an embodiment of the present invention, a floor heating pipe arrangement and fixing device for building construction, including a fixing cylinder 1, the upper surface of the fixing cylinder 1 is provided with spikes 2, and the upper surface of the fixing cylinder 1 corresponds to the spikes 2 A through hole 8 is vertically opened at the position of the fixed cylinder 1. Two connecting ears 3 distributed up and down are fixed on the side wall of the fixed cylinder 1, and the second limit card 7 and the first limit card are arranged side by side on one side of the fixed cylinder 1. 6. Both the first limit card 6 and the second limit card 7 are made of heat-resistant ABS material, and both the first limit card 6 and the second limit card 7 have an "n" shape structure. When in use, they can Clamp the limit card to the floor heating pipe, so as to realize the fixing of the floor heating pipe.

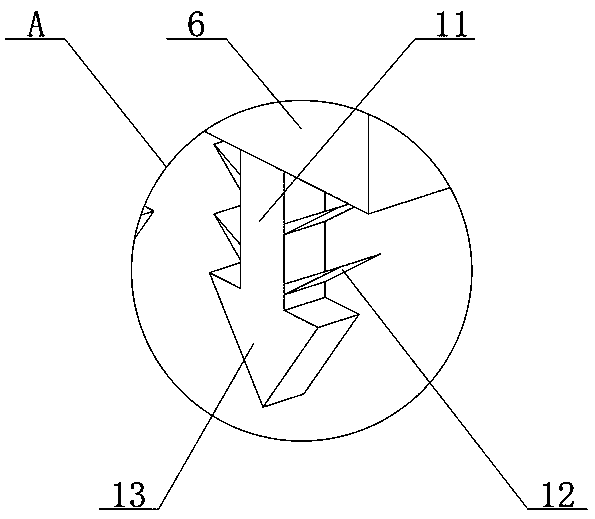

[0022] The inner sides of the second limit card 7 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com