Automatic sealing ring assembling device based on mechanical arm

An automatic assembly and robotic arm technology, applied in the field of robotic arms, can solve the problems of low assembly efficiency and high labor cost of sealing rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

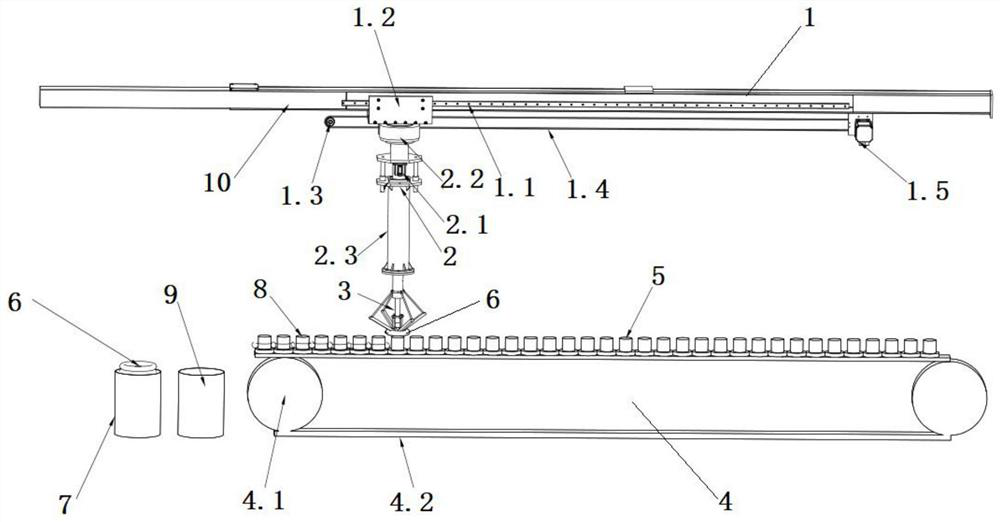

[0028] see figure 1 , figure 2 , an automatic assembly sealing ring device based on a mechanical arm, including a horizontal transmission mechanism 1, a lifting mechanism 2, a manipulator 3, and a material transportation mechanism 4; the horizontal transmission mechanism 1 includes a guide rail 1.1 and a slider 1.2 that cooperates with the guide rail; the guide rail is installed on On the beam 10, the slider 1.2 can slide in the horizontal direction along the guide rail 1.1; one end of the lifting mechanism 2 is connected with the slider 1.2, and the other end is connected with the manipulator 3; the material conveying mechanism 4 is arranged under the manipulator 3; the product 5 to be assembled is placed On the material conveying mechanism 4, the sealing ring 6 is grasped by the manipulator 3 to realize product assembly; the product with assembly in this embodiment is an exhaust valve;

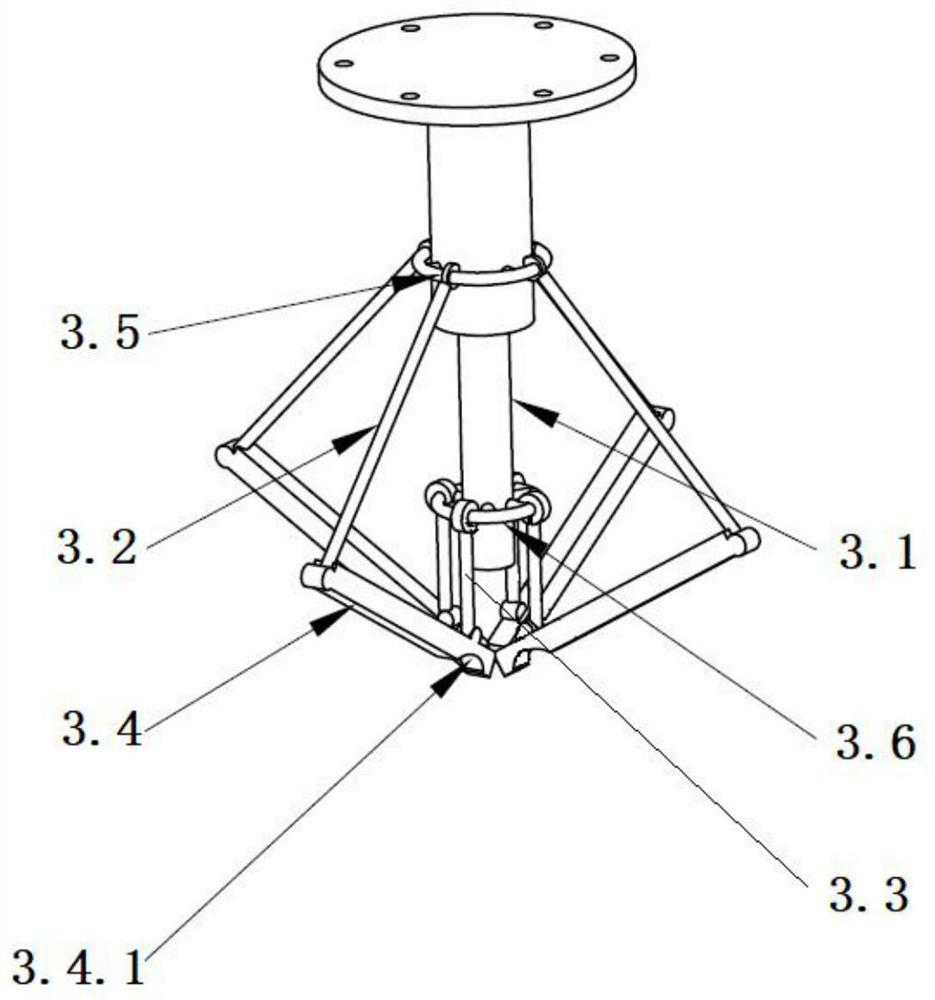

[0029] The manipulator 3 includes a second telescopic member 3.1 and a grabbing assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com