Installation structure of assembled door pocket

An installation structure and assembly technology, applied in the field of door covers, can solve the problems of reduced durability, low performance strength, customization cycle, etc., and achieve the effect of increasing stability and strength, improving construction efficiency, and convenient construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

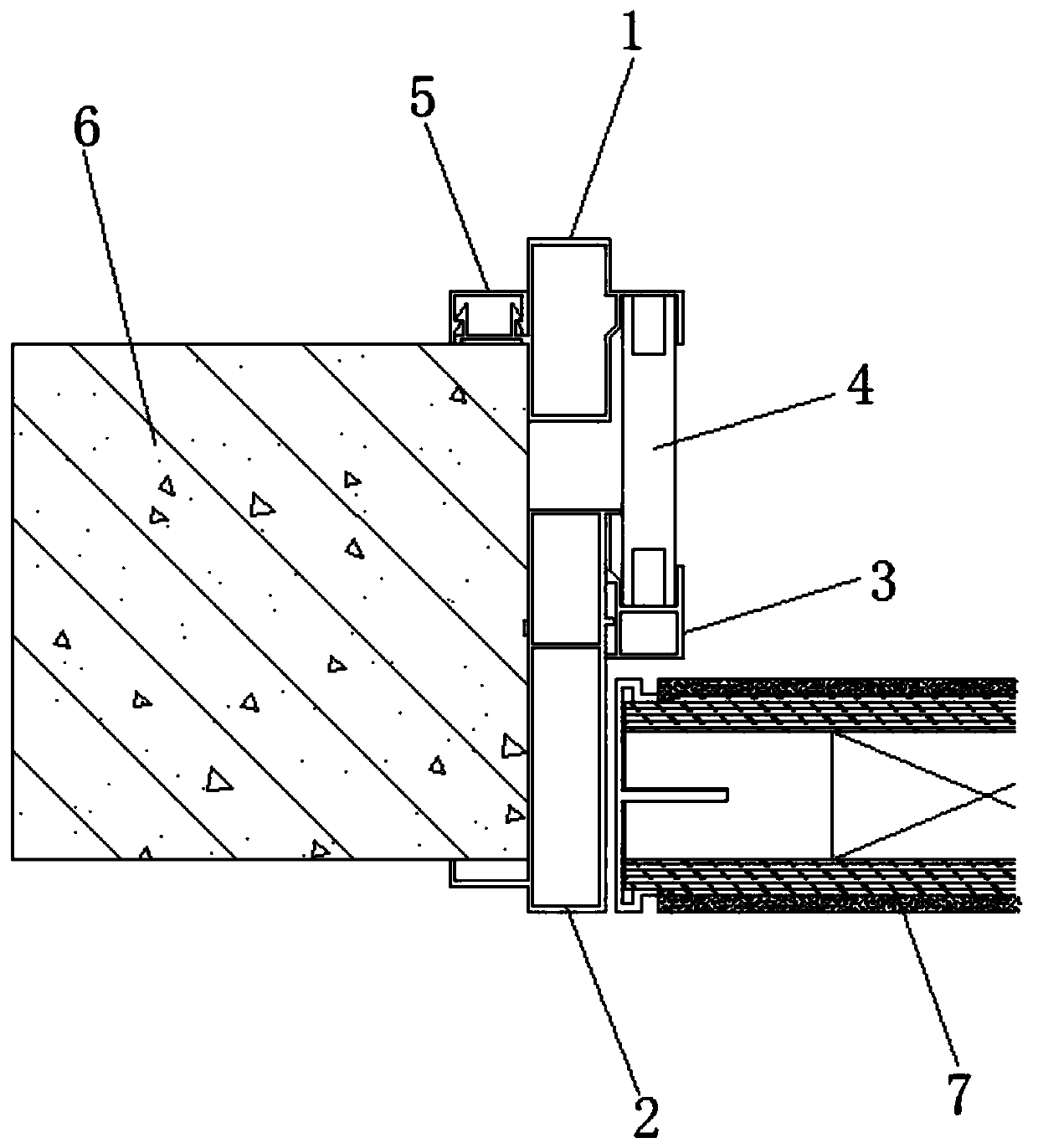

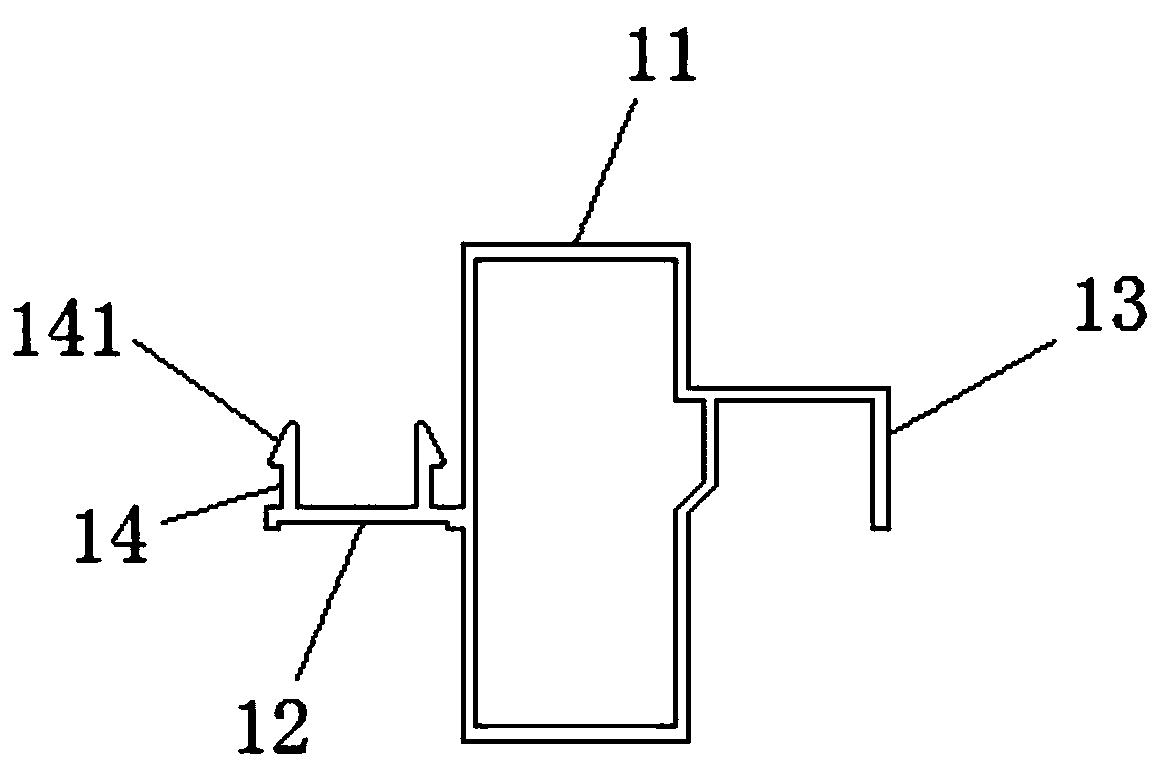

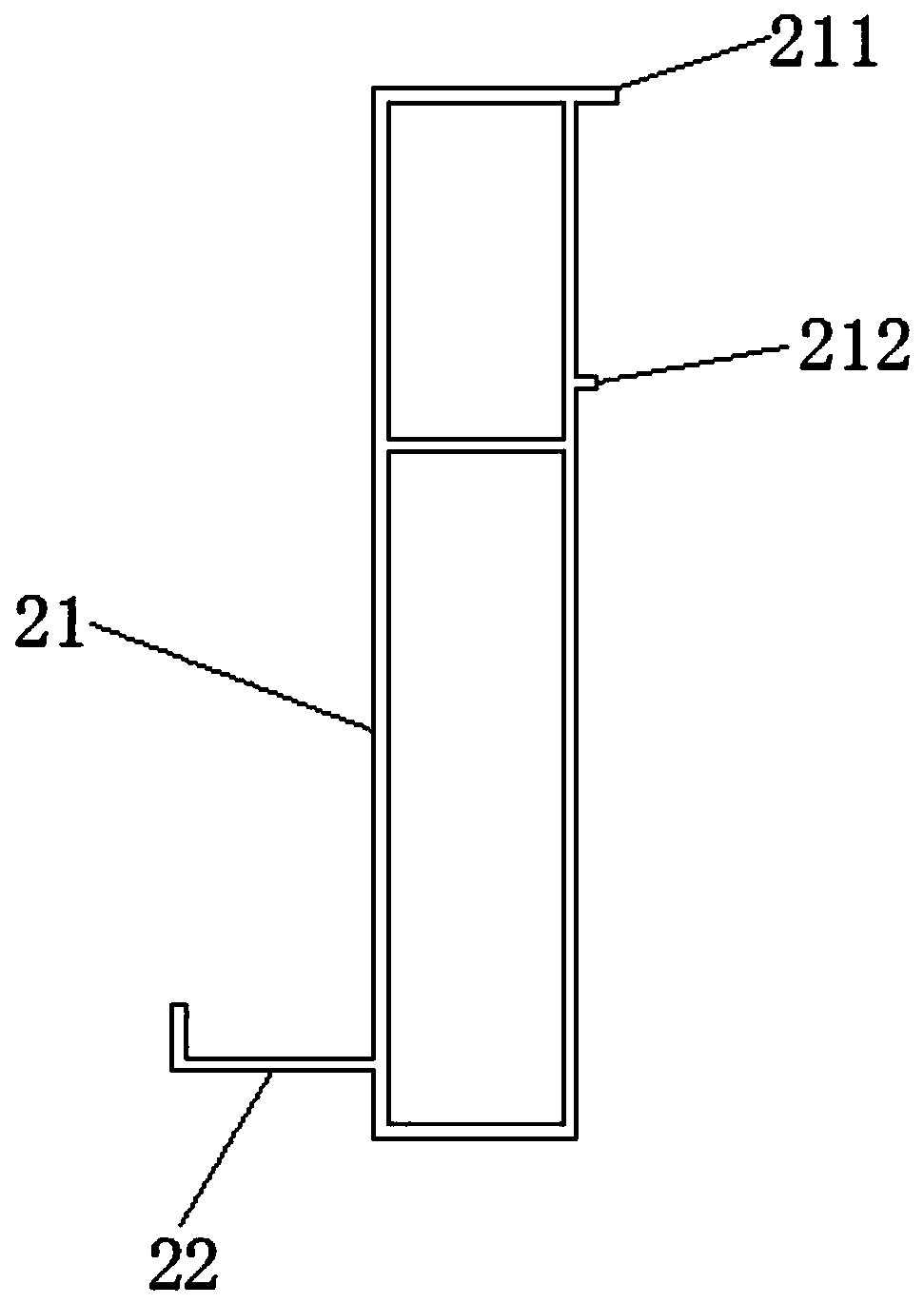

[0042] see figure 1 , the figure shows an installation structure of an assembled door cover provided by Embodiment 1 of the present invention, including: an indoor door frame 1, including a first frame body 11 and a first buckle 12 arranged on the first frame body 11 and the second buckle 13, the first buckle 12 and the second buckle 13 are respectively located on both sides of the first frame body 11, and the inner side of the first buckle 12 is connected with the corner of the indoor wall 6; the outdoor door frame 2, Including the second frame body 21 and the closing frame 22 arranged at the bottom of the second frame body 21, the second frame body 22 is set on the doorway wall 6, and the closing frame 22 is set close to the outdoor wall body 6; the door frame baffle 3, It is connected to the outside of the second frame body 21; the top and bottom of the veneer 4 are engaged with the second buckle 13 and the door frame baffle 3 respectively; the cover plate 5 is arranged on ...

Embodiment 2

[0050] see Figure 1 to Figure 2, the figure shows the installation structure of a prefabricated door cover provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first card The buckle 12 and the second buckle 13 are "L" shaped; the outside of the first buckle 12 is provided with a pair of clip strips 14, and the top of the clip strips 14 is provided with a first hook 141; the two first hooks 141 are symmetrical set, and are all set downwards and outwards by the top of the clip bar 14. Through the setting of the above structure, the "L"-shaped buckle design is convenient for clamping, and the connection effect is good; the first hook 141 on the clamping strip 14 can facilitate the installation of the cover plate 5 and improve the installation efficiency.

Embodiment 3

[0052] see figure 1 , figure 2 and Figure 5 , the figure shows the installation structure of a prefabricated door cover provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: cover plate 5 It is "U"-shaped; the inner side wall of the cover plate 5 is provided with a second hook 51 corresponding to the first hook 141 , and the second hook 51 is inclined toward the inner side of the cover plate 5 from bottom to top. Through the setting of the above structure, the opposite side walls of the cover plate 5 just correspond to the clips 14, and the second hook 51 is engaged with the first hook 141 correspondingly, so that the cover plate 5 is firmly locked to prevent loosening. Phenomenon, to further improve the connection strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com