Battery test extrusion platform

A battery testing and platform technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of inaccurate test results, inability to guarantee the consistency of applied pressure, etc., and achieve low price and cost performance. High and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

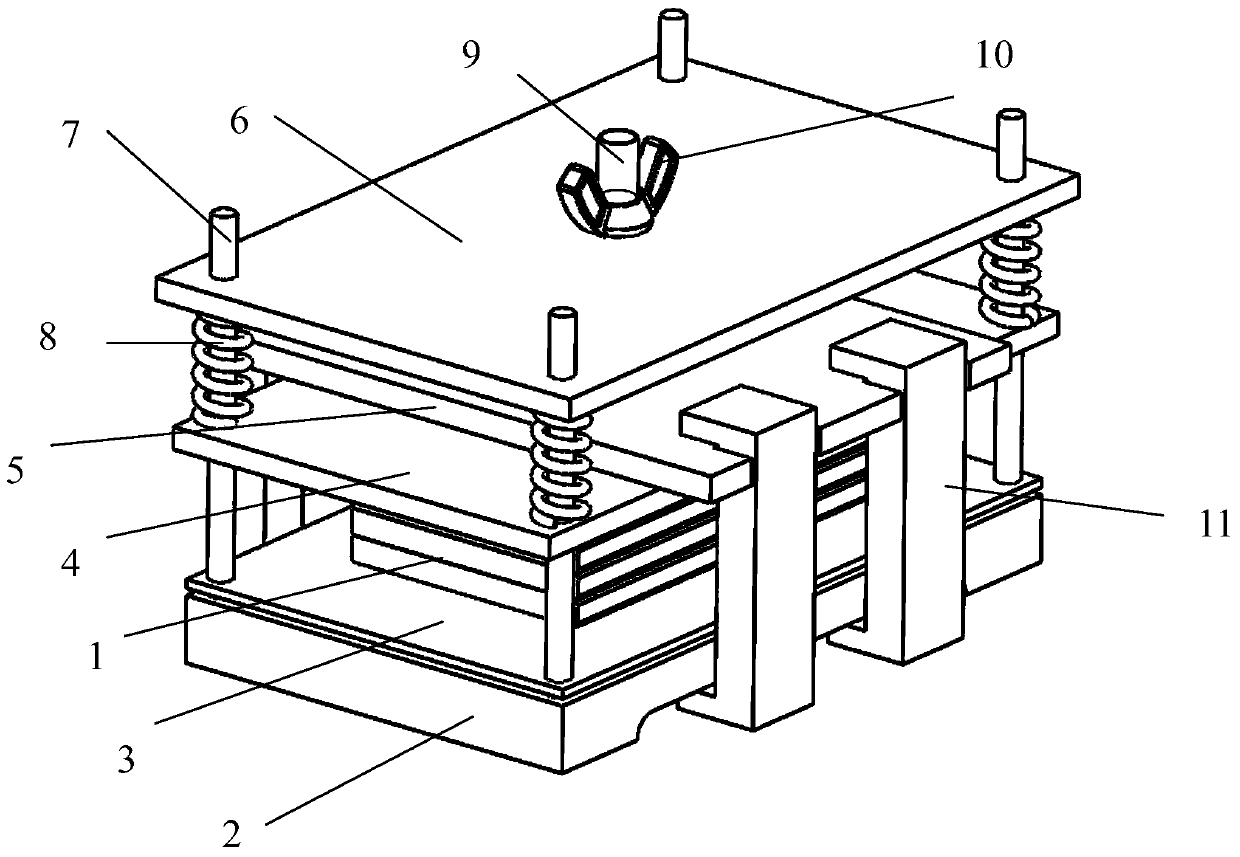

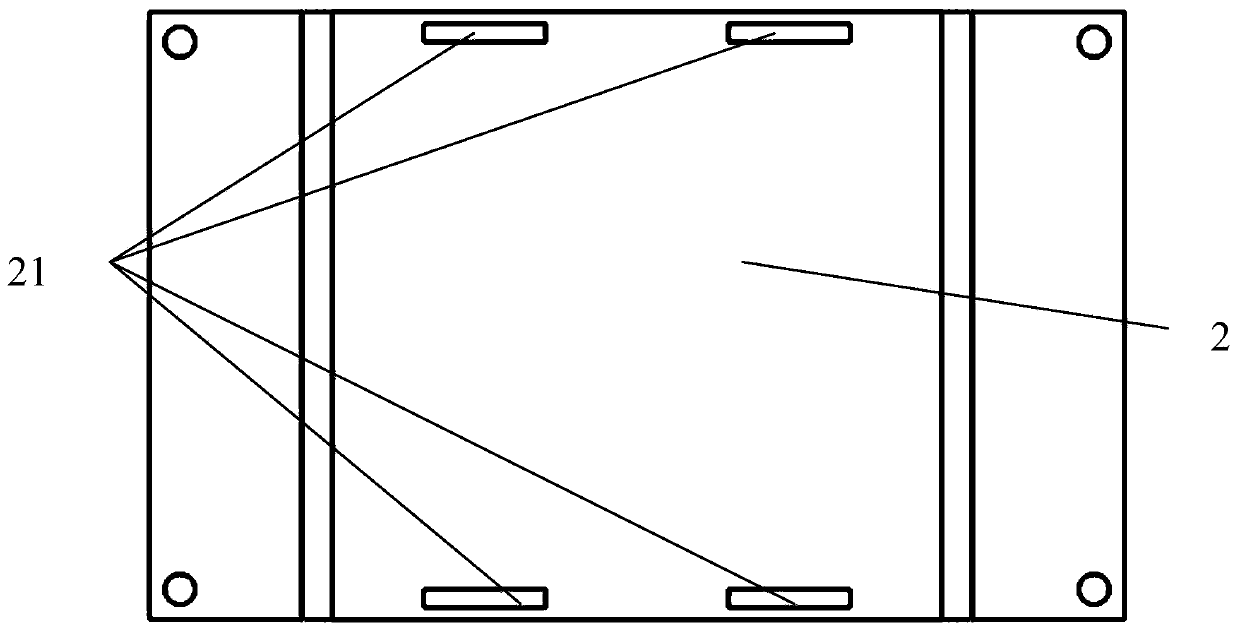

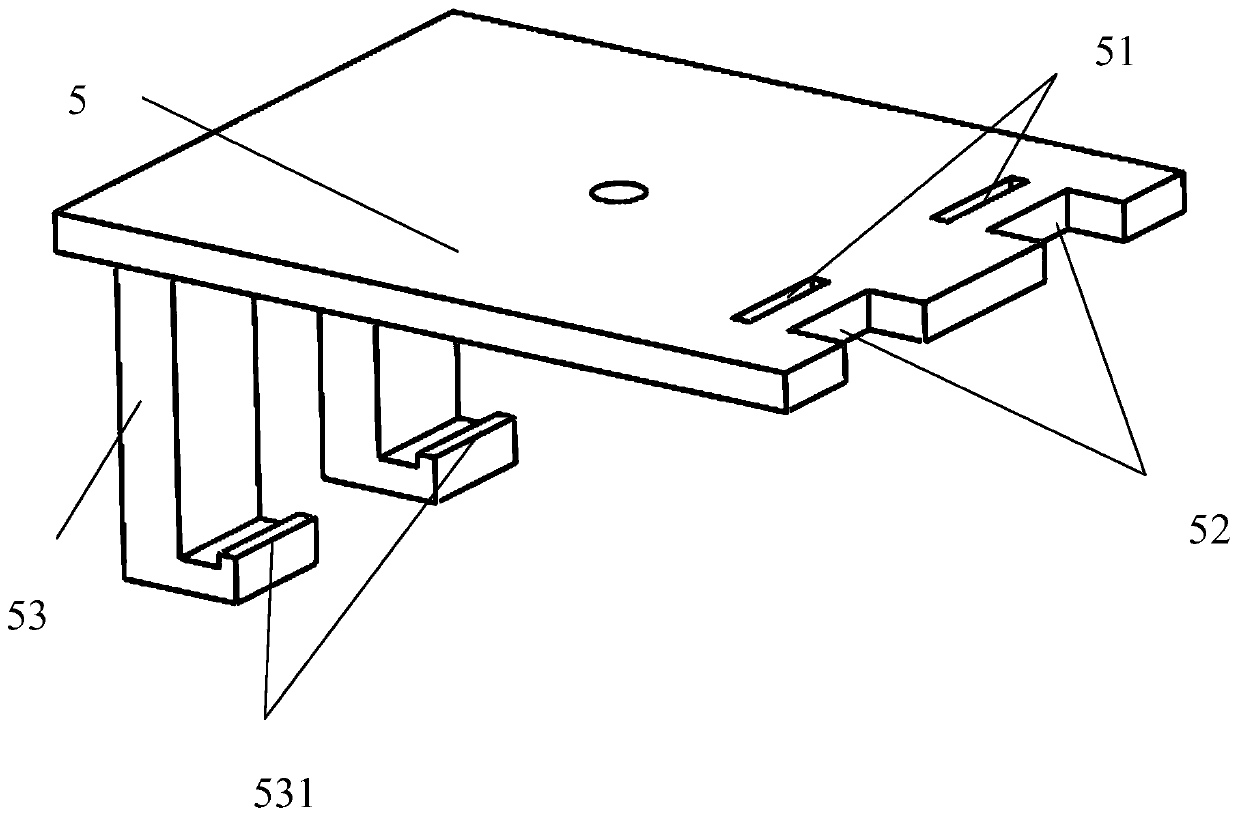

[0020] A battery test extrusion platform, refer to Figures 1 to 4 , comprising a base plate 2, a pressure strain gauge baffle plate 3, a force plate 4, a stud fixing plate 5, a force transmission plate 6, a spring 8 and a column 7 arranged sequentially from top to bottom; the base plate 2, the pressure strain gauge baffle plate The plate 3, the force plate 4, and the force transmission plate 6 are all provided with relief holes symmetrically along the center; All up and down one-to-one correspondence; the column 7 passes through the relief holes on the bottom plate 2, the pressure strain gauge baffle plate 3, the force plate 4, and the force transmission plate 6 in turn. In this embodiment, the column 7 There are four, respectively arranged on the four corners of the bottom plate 2, the pressure strain gauge baffle plate 3, the force plate 4,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap