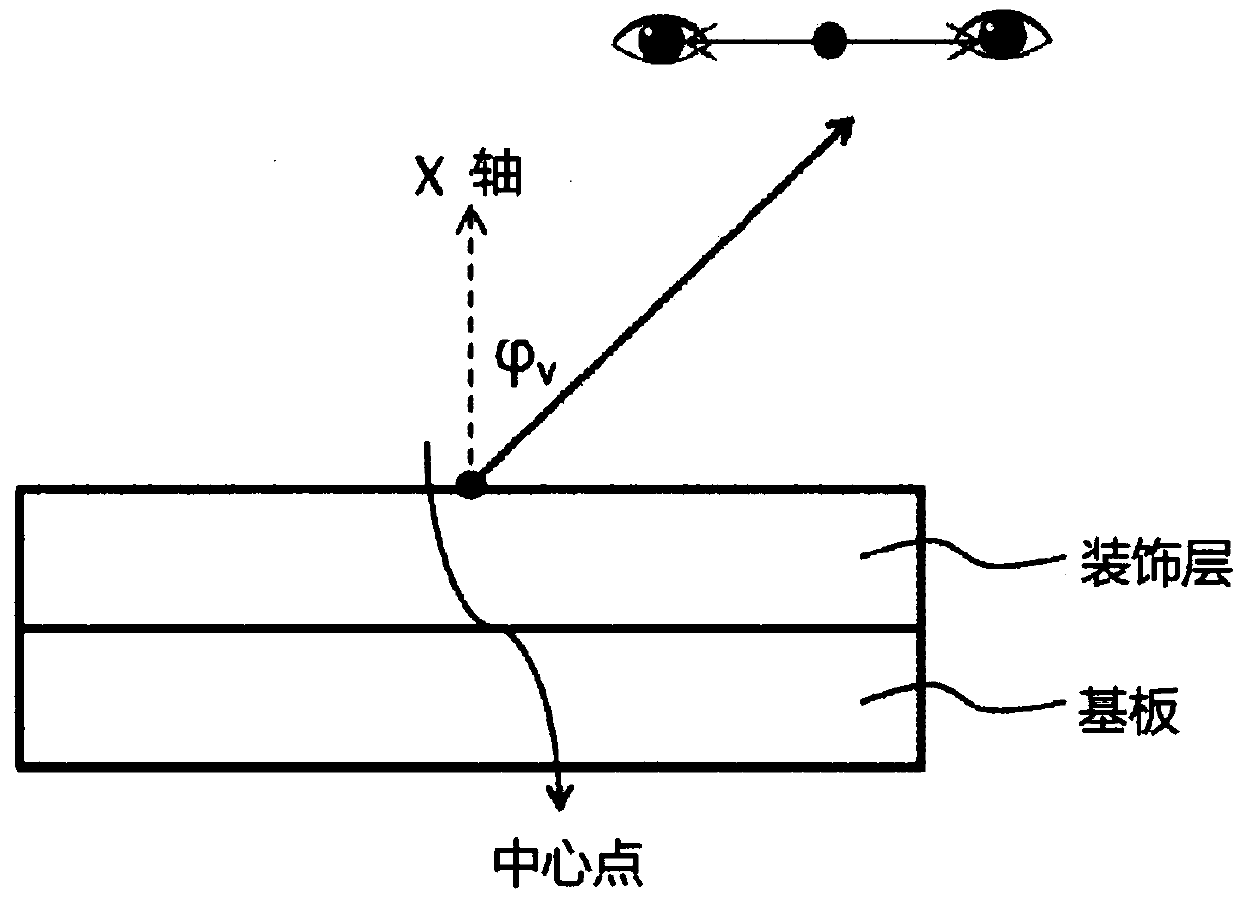

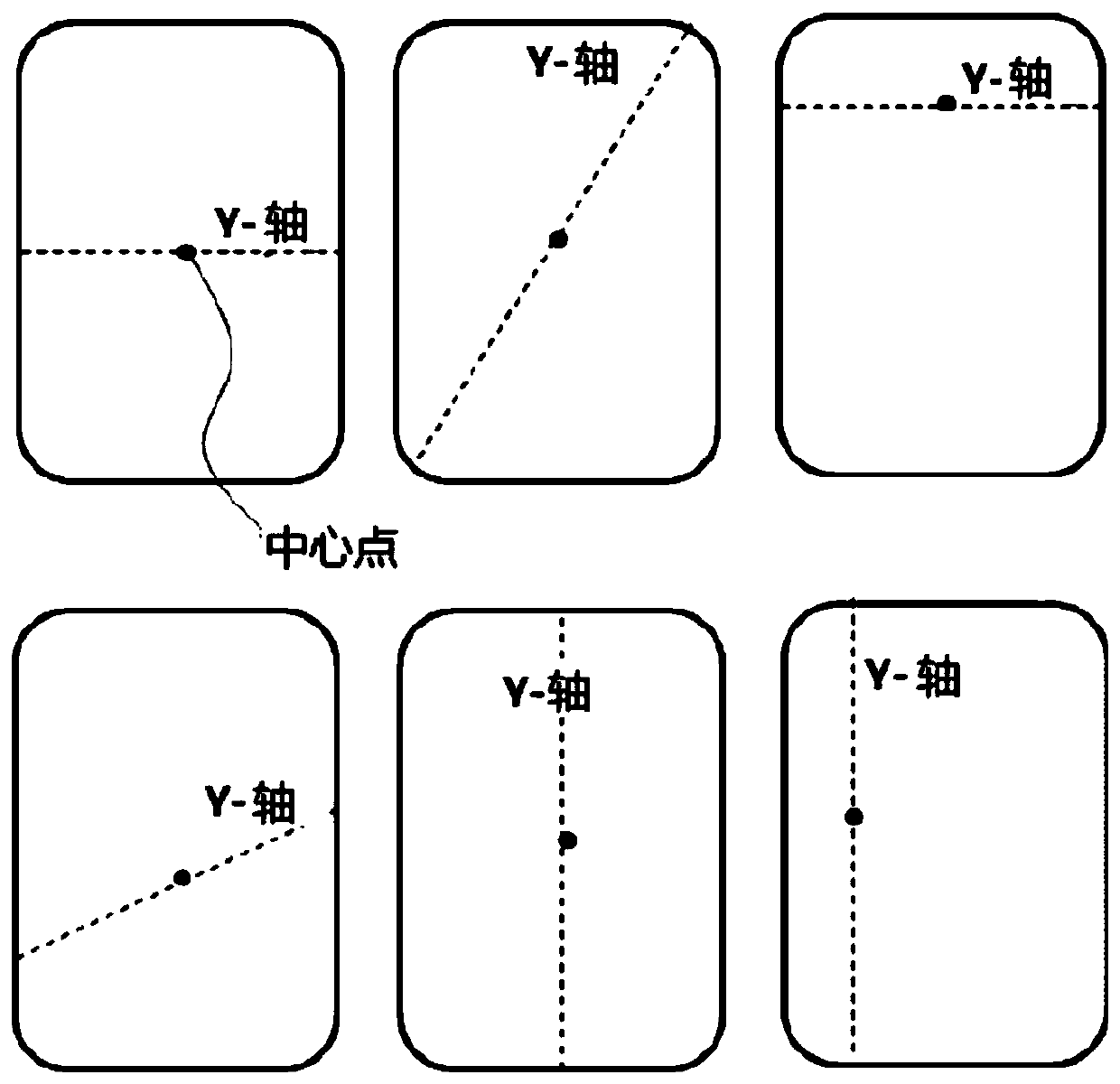

Decoration member and manufacturing method therefor

A technology for decorative components and decorative layers, which can be applied to decorations, decorative arts, and other home appliances, and can solve problems such as differences in color perception and implementation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 4、 comparative example 1 to 3

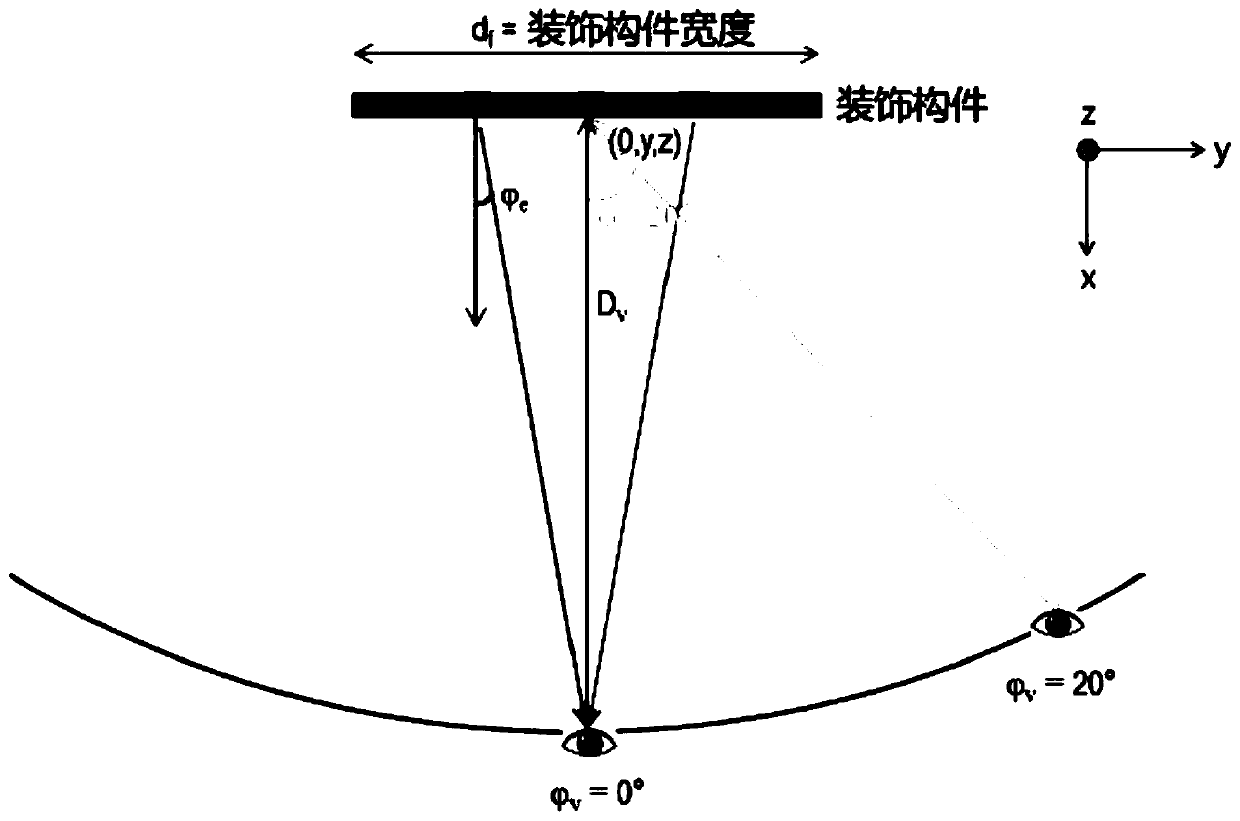

[0348] For film #1 to film #7, depending on the central viewing angle under the conditions of θv = 90° and Dv = 500mm The depth parameter value δ of Equation 1 1m shown in Table 2 and Figure 8 middle. A PET film was used as the substrate, film #1 is a flat film made of aluminum comprising a mirror thermally deposited as a decorative layer, film #2 is a film comprising aluminum oxide deposited on an unpatterned plane, film #3 is A non-prism patterned film comprising a colloidal absorbing layer, more specifically, a colloidal absorbing layer patterned film having a rectangular cross-section with a pitch of 200 μm, a filling factor of 25%, and a height of 50 μm, wherein the filling factor is defined as the filled colloidal absorbing Ratio of layers relative to a total pitch of 200 μm, film #4 is an asymmetric prism film made of alumina and has a pitch of 77.8 μm, a height of 25 μm, and a base angle of 20° / 70°, film #5 is made of oxide An asymmetric prism film made of aluminu...

Embodiment 5

[0362] Asymmetric prism films were tested in the same manner as the asymmetric prism film of Film #4 (Example 2), except that the pitch was changed to 0.1 mm. The angular brightness at the center of the trim member is shown in Figure 27 middle. In addition, the angular luminance at a point 2.5 mm from the center of the decorative member is shown in Figure 28 middle. from Figure 27 and Figure 28 It can be seen that when the pitch of the pattern of the decorative member is less than 1 mm, the angular brightness at the center of the decorative member is the same as that at a point 2.5 mm from the center of the decorative member.

example 6

[0364] Asymmetric prism films were tested in the same manner as the asymmetric prism film of Film #4 (Example 2), except that the pitch was changed to 10 mm. The angular brightness at the center of the trim member is shown in Figure 29 middle. In addition, the angular luminance at a point 2.5 mm from the center of the decorative member is shown in Figure 30 middle. from Figure 29 and Figure 30 It can be seen that when the pitch of the pattern of the decorative member is greater than 1 mm, the angular brightness at the center of the decorative member is the same as that at a point 2.5 mm from the center of the decorative member.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom corner | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com