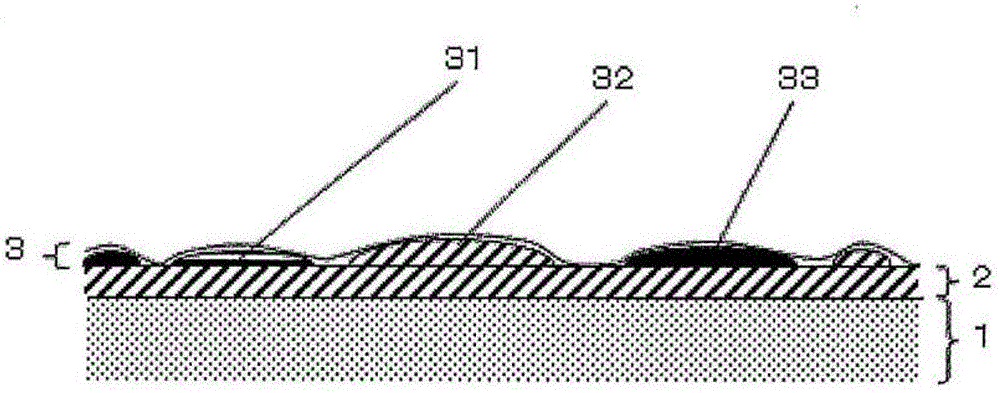

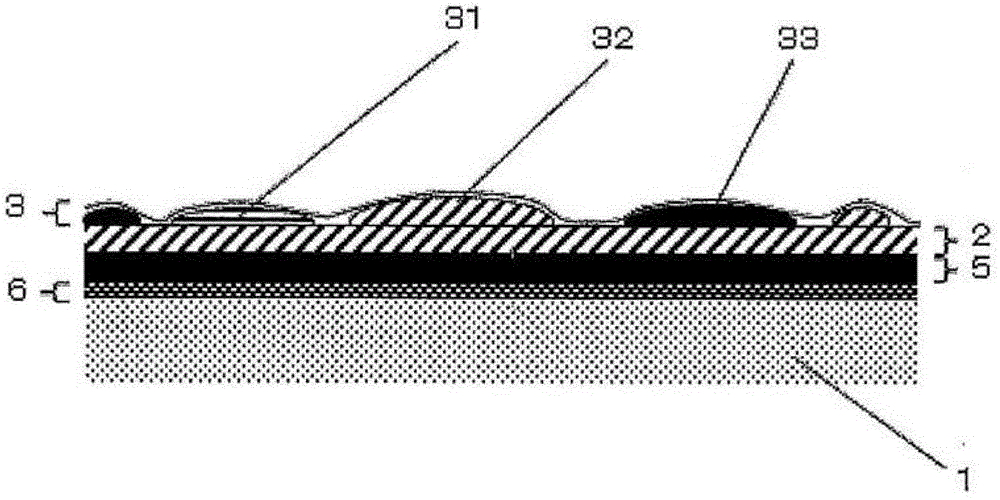

Coating material, coating material layer, and laminated structure

A technology for coating materials and structures, applied in coatings, multi-color effect paints, latex paints, etc., can solve the problems of difficulty in reproducing specific patterns, difficulty in obtaining a sense of depth of natural stone, temperature rise, etc. The effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0186] The following examples further clarify the characteristics of the present invention.

[0187] (Manufacture of coloring materials)

manufacture example A

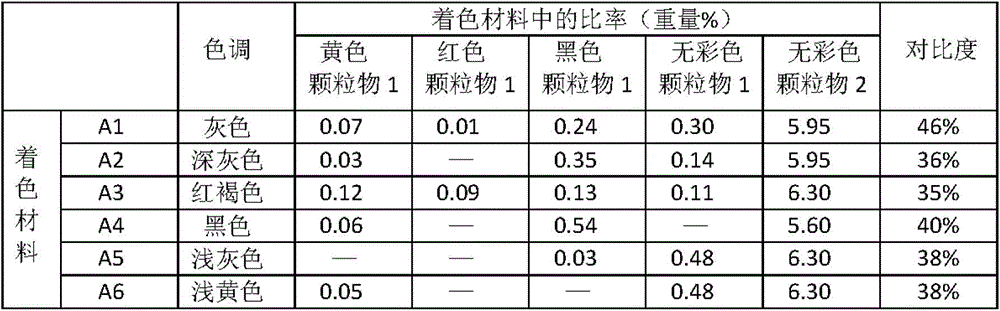

[0188] ○ Production Example A (Production of Coloring Materials A1 to A6)

[0189] 100 parts by weight of acrylic resin latex 1 (solid content of 40% by weight, 60% by weight of water) was prepared in a container, and 6 parts by weight of solvent 1 (propylene glycol monobutyl ether, solubility in water 6.0g / 100g), 80 parts by weight were mixed Gel-forming substance 1 (a 3 wt % aqueous solution of galactomannan), 2 parts by weight of antifoaming agent 1 (mineral oil base), and various particulate matter were further mixed to produce each coloring material. The kind and ratio of particulate matter (% by weight in the coloring material), and the contrast ratio of the coloring material are shown in Table 1. The contrast ratio of the coloring material was calculated by measuring the visual reflectance of the test piece obtained by coating the coloring material on the contrast test paper with a film coater (gap 300 μm) and drying it in a standard state for 48 hours.

[0190] Each p...

manufacture example B

[0201] ○ Production Example B (Production of Coloring Materials B1 to B4)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com