hinge hinge

A technology of chain leaf and hinge, applied in the field of hinge leaf of hinge, can solve the problems of high cost and time-consuming work steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

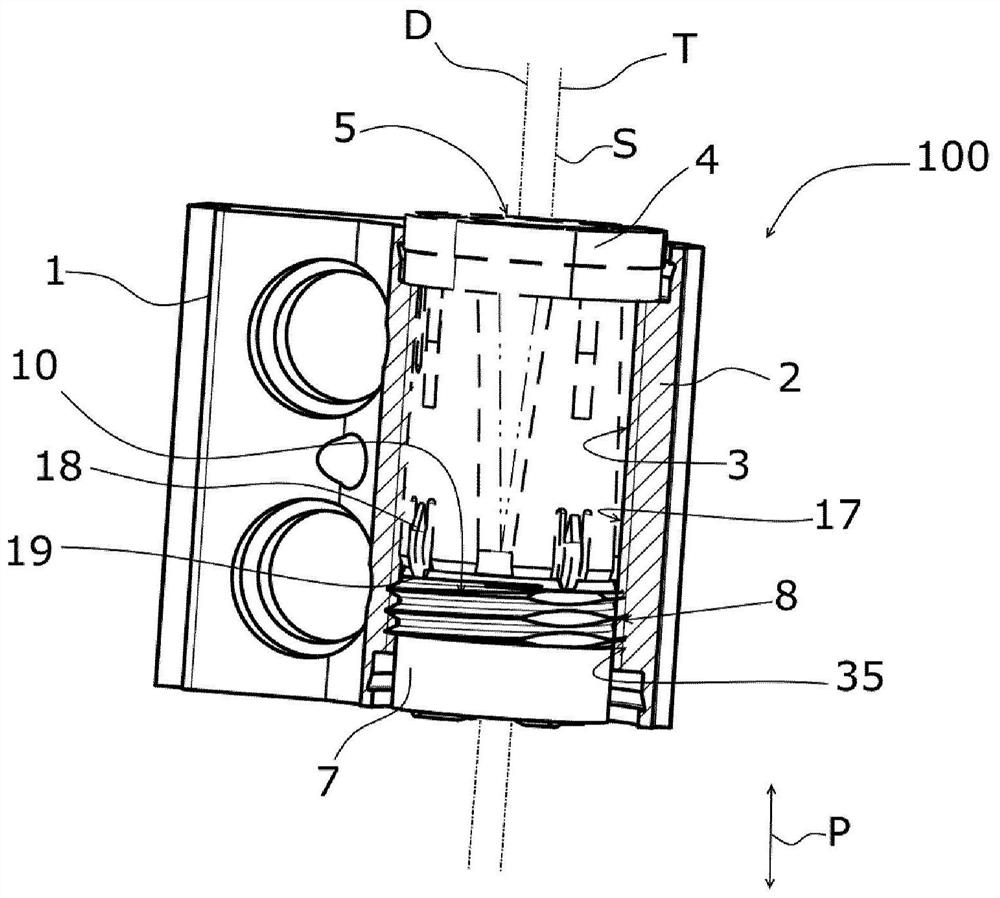

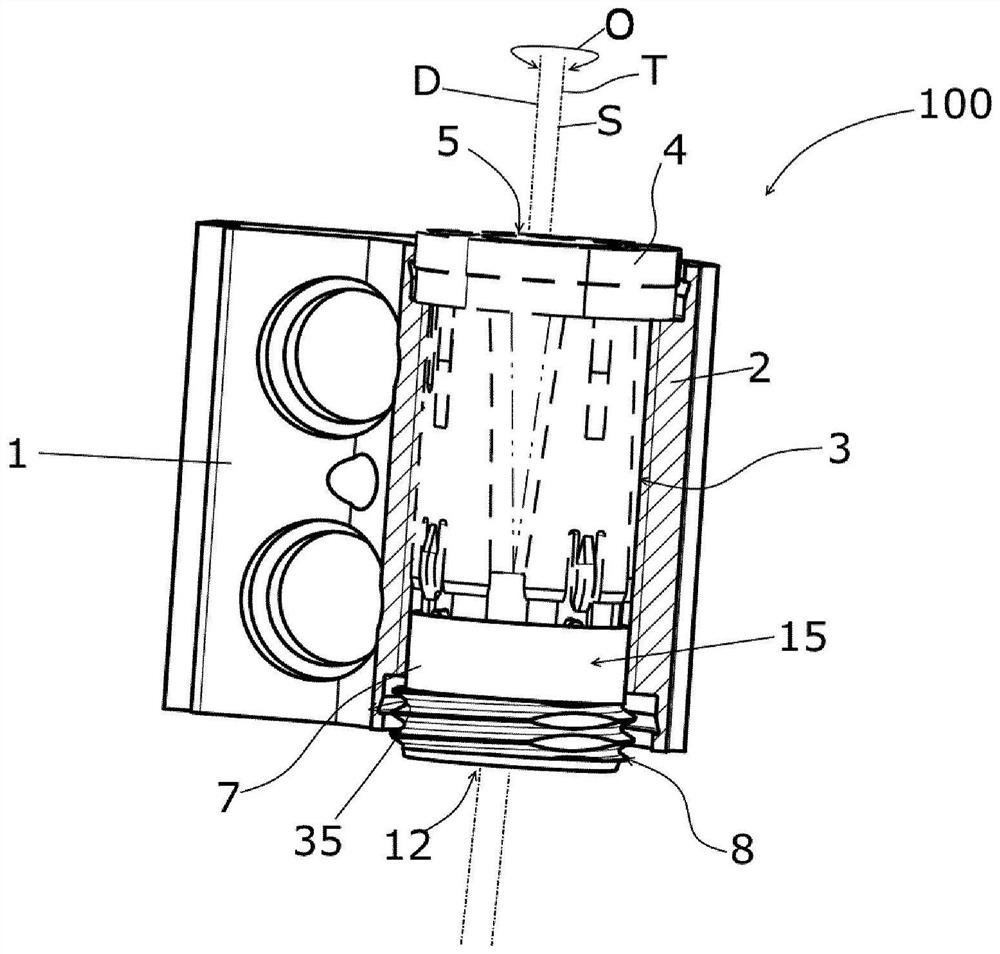

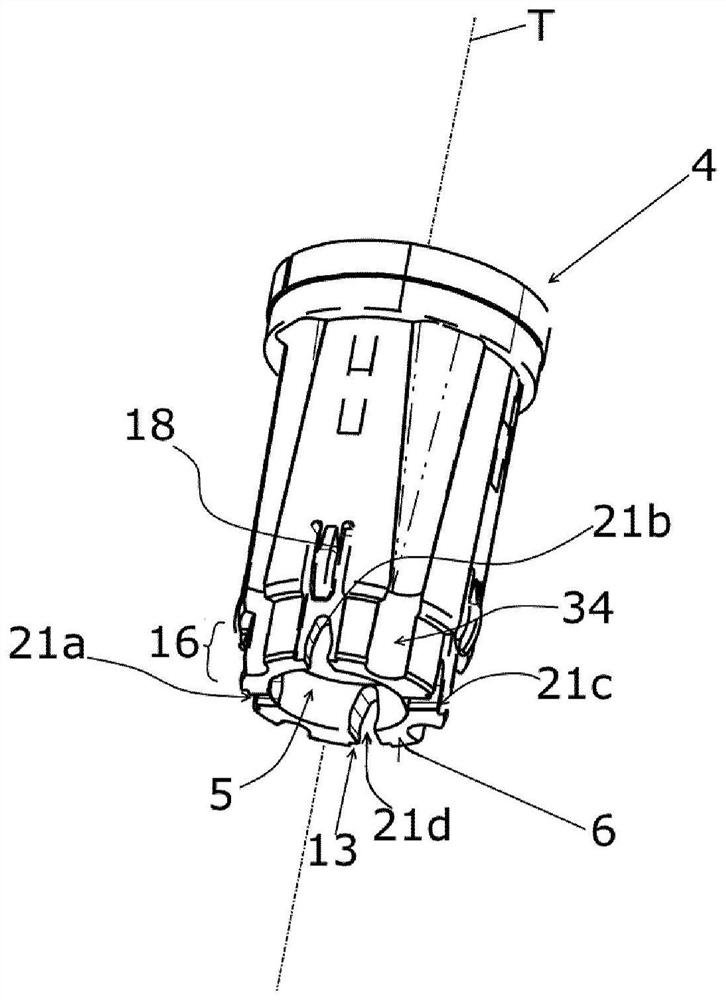

[0029] The exemplary embodiment of the hinge leaf 100 according to the invention shown in the drawing is part of a hinge for the hinged connection of a leaf (not shown) about a hinge axis S to a frame. The hinge leaf 100 is shown as a frame hinge leaf.

[0030] The hinge leaf 100 includes a fastening element 1 which, in the exemplary embodiment shown, serves for fastening to a frame. A hinge part 2 is formed onto said fixing part 1 . The hinge part 2 comprises a longitudinal recess 3 in which a bearing sleeve 4 is arranged. The bearing sleeve is arranged rotatably about an axis of rotation D parallel to the hinge axis S, but offset laterally, by means of a rotation aid 12 which will be described in more detail. An internal thread 35 is provided in the longitudinal recess 3 . Lifting spindles 7 , 7 ′ with an external thread 8 complementary to internal thread 35 are screwed into internal thread 35 from below with respect to the operating position of hinge leaf 100 .

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com