Thermal shaping jig

A thermal shaping and jig technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as product side crushing and product defects, and achieve the effect of improving product yield and avoiding crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

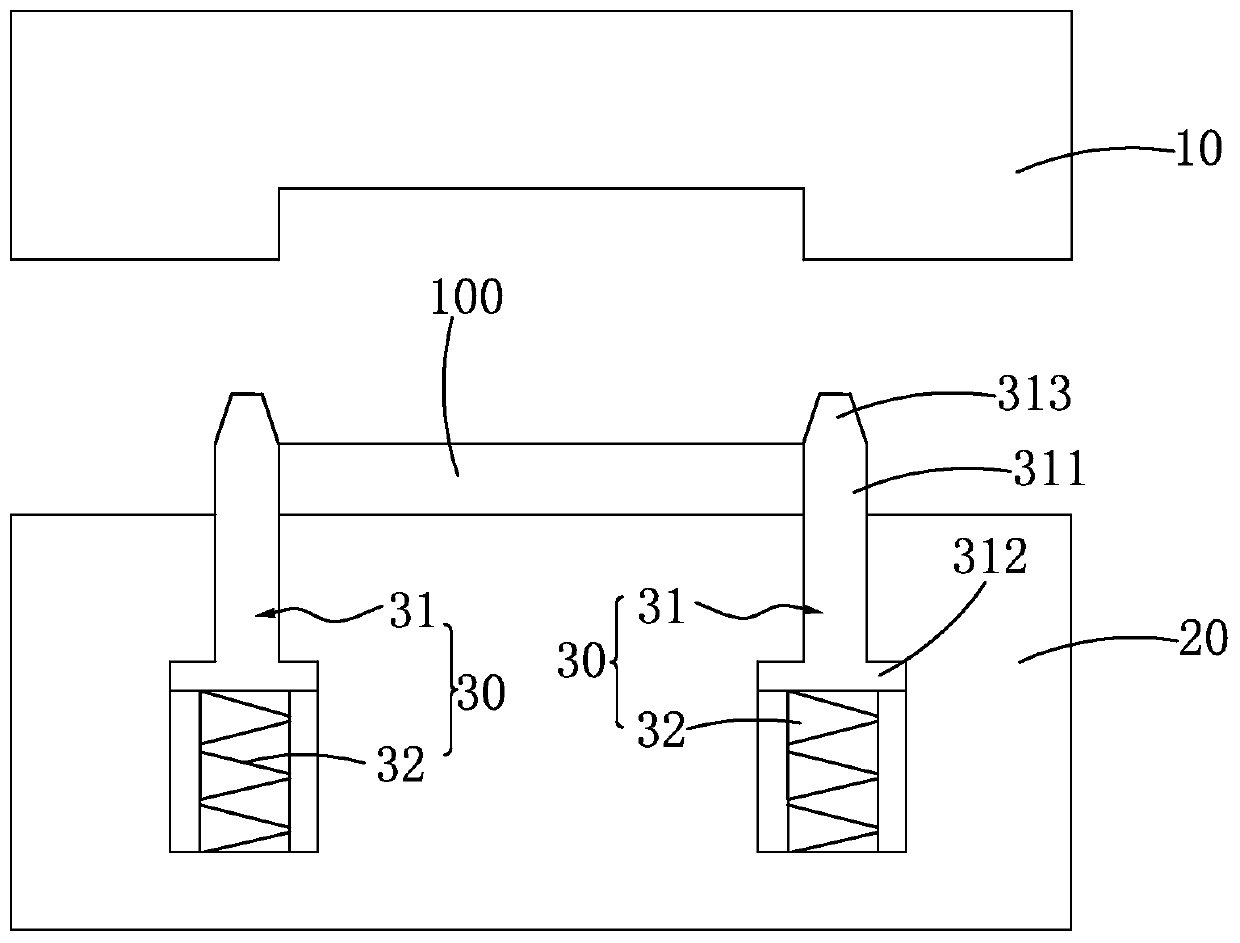

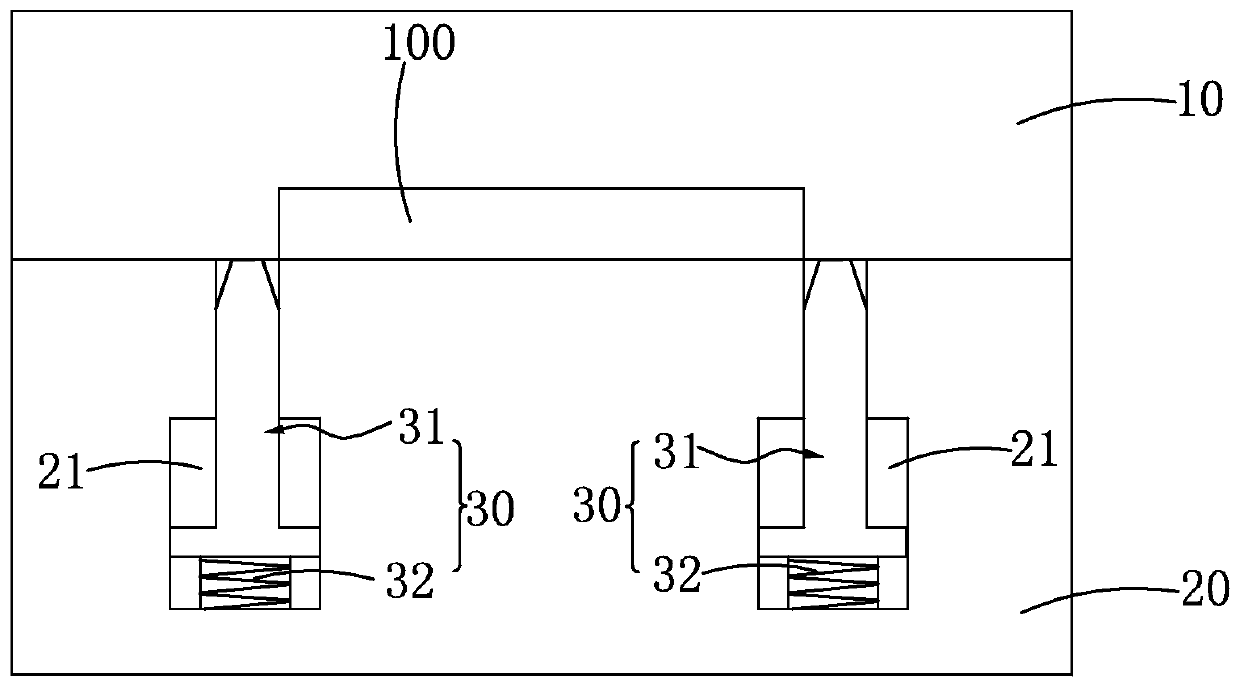

[0019] Such as Figure 1-2 As shown, a thermal shaping fixture includes an upper mold 10 and a lower mold 20; the lower mold 20 is provided with at least one pair of elastic positioning components 30 for positioning the product 100 to be shaped; each elastic positioning component 30 includes a positioning column 31 And elastic member 32. Wherein, the positioning column 31 is accommodated in the lower mold 20, and the top of the positioning column 31 can move out of the lower mold 20 along the mold opening direction; the elastic member 32 is connected to the bottom surface of the positioning column 31, and can expand and contract along the mold opening direction. When opening the mold, the positioning column 31 stretches out of the lower mold 20 under the elastic force of the elastic member 32;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com