Disassembling tool of steering gear outer sphere head and steering knuckle

A technology for dismantling tooling and steering gear, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of surface treatment damage of peripheral parts, easy knocking of peripheral parts, damage to the taper of steering knuckles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

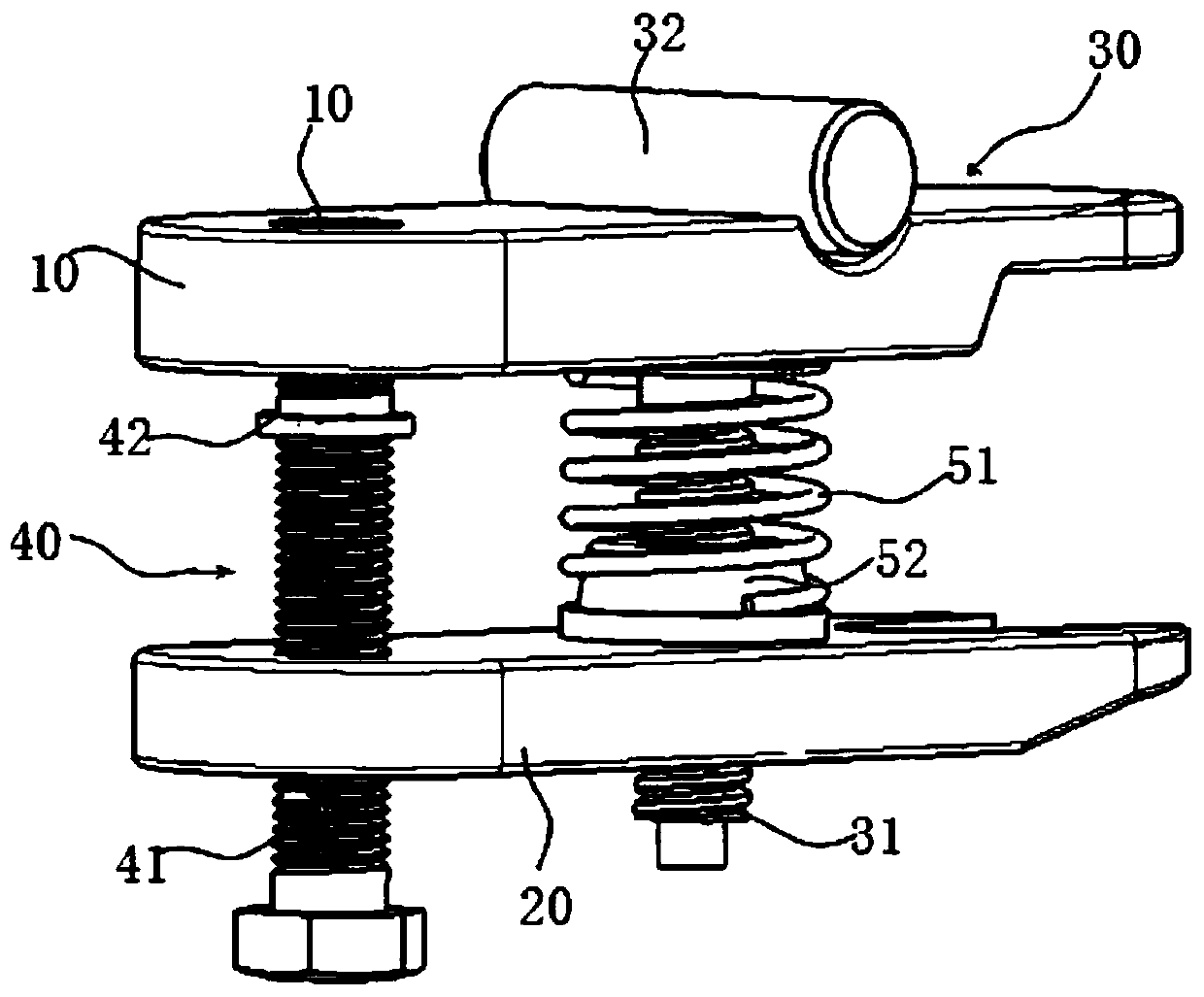

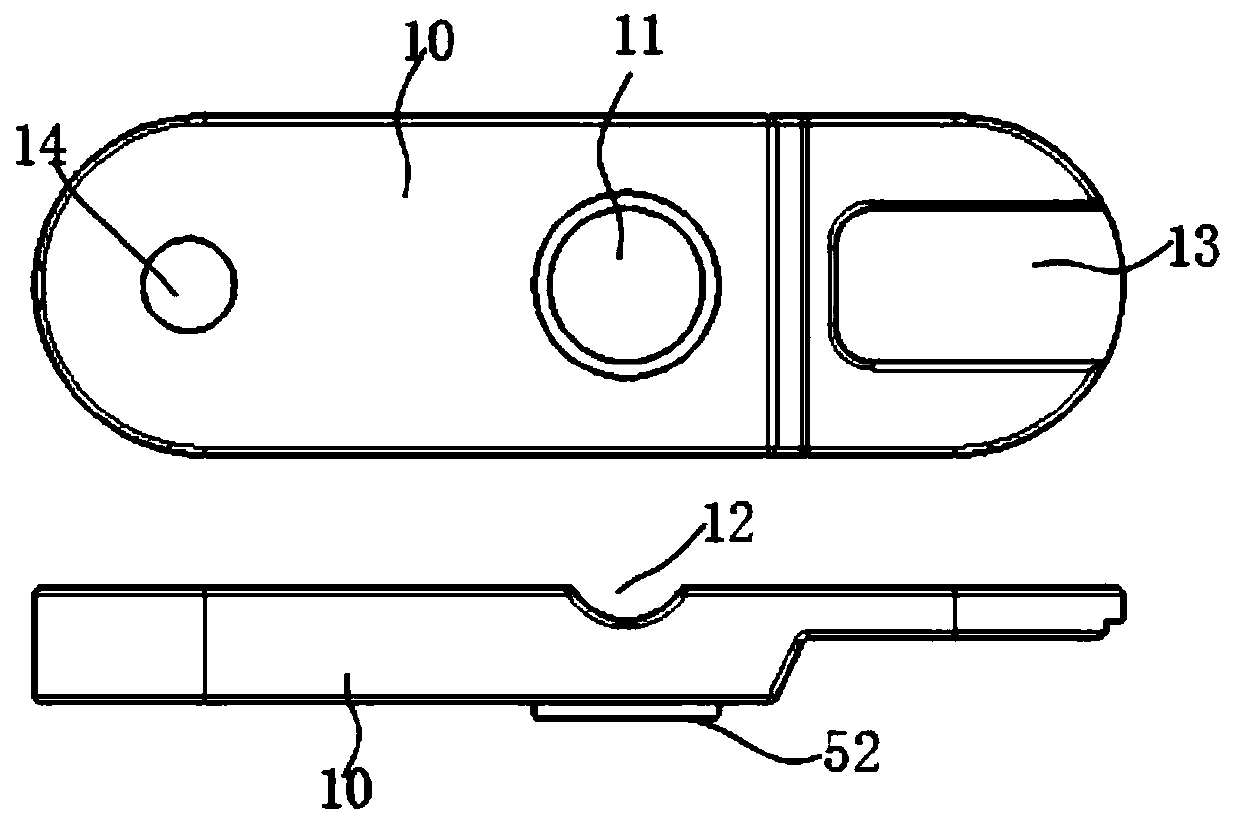

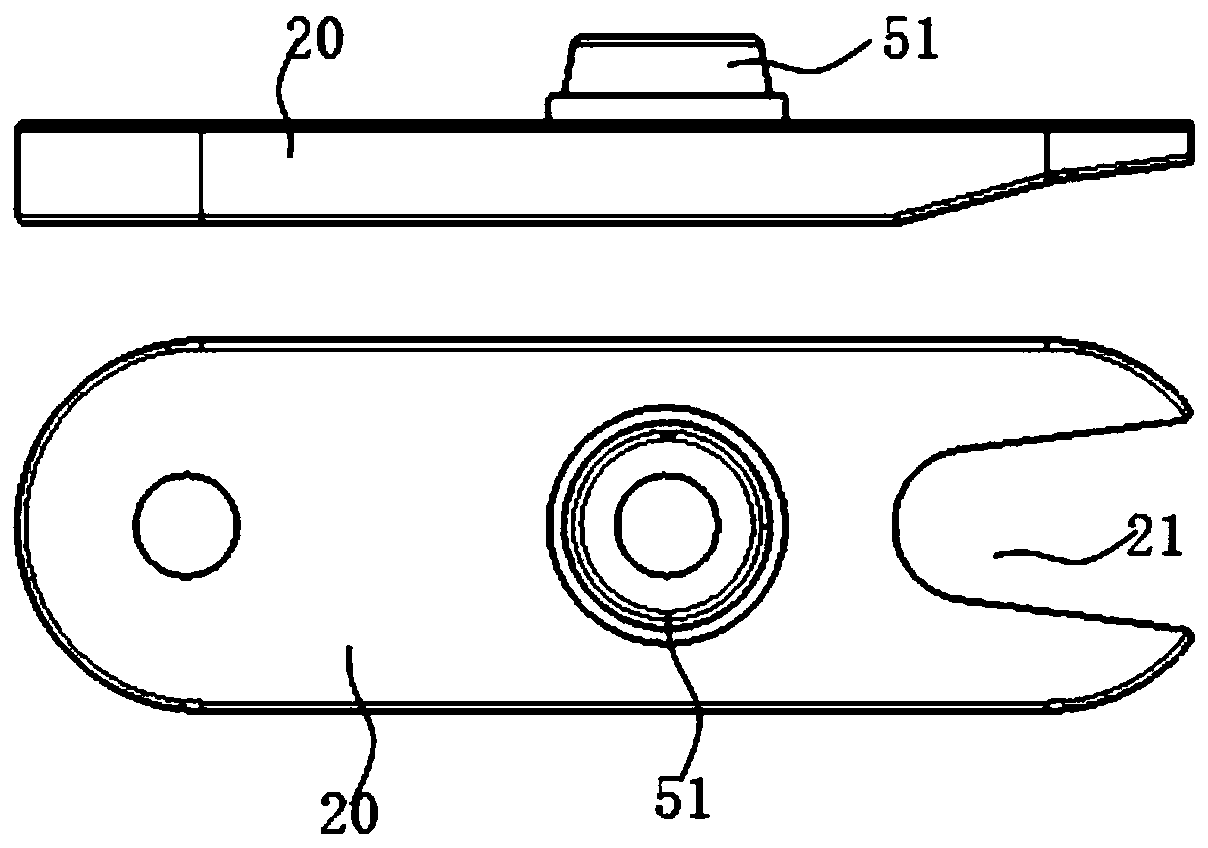

[0010] combine Figure 1-Figure 4 , a dismantling tool for the outer ball head of the steering gear and the steering knuckle, the middle part of the strip-shaped upper and lower plates 10, 20 has a connecting support portion 30, and the upper and lower plates 10, 20 at the same end form an open-close type clamp The other end away from the jaws is provided with an adjustment mechanism 40 for adjusting the distance between the upper and lower plates 10, 20. Using the principle of leverage, the adjustment mechanism 40 adjusts the distance between the upper and lower plates 10, 20 of the end to become larger, and the other end, that is, the jaws, will be closed, and the upper plate 10 presses the outer ball head A of the steering gear to make the ball head turn from Knuckle bracket B falls off, thus completing the disassembly of steering gear outer ball joint A and steering knuckle.

[0011] The lower end of the connecting support part 30 is connected to the lower plate 20, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com