Gapless grooving saw blade

A grooving saw, no gap technology, applied in stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems of unfavorable self-priming function, low efficiency, low precision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

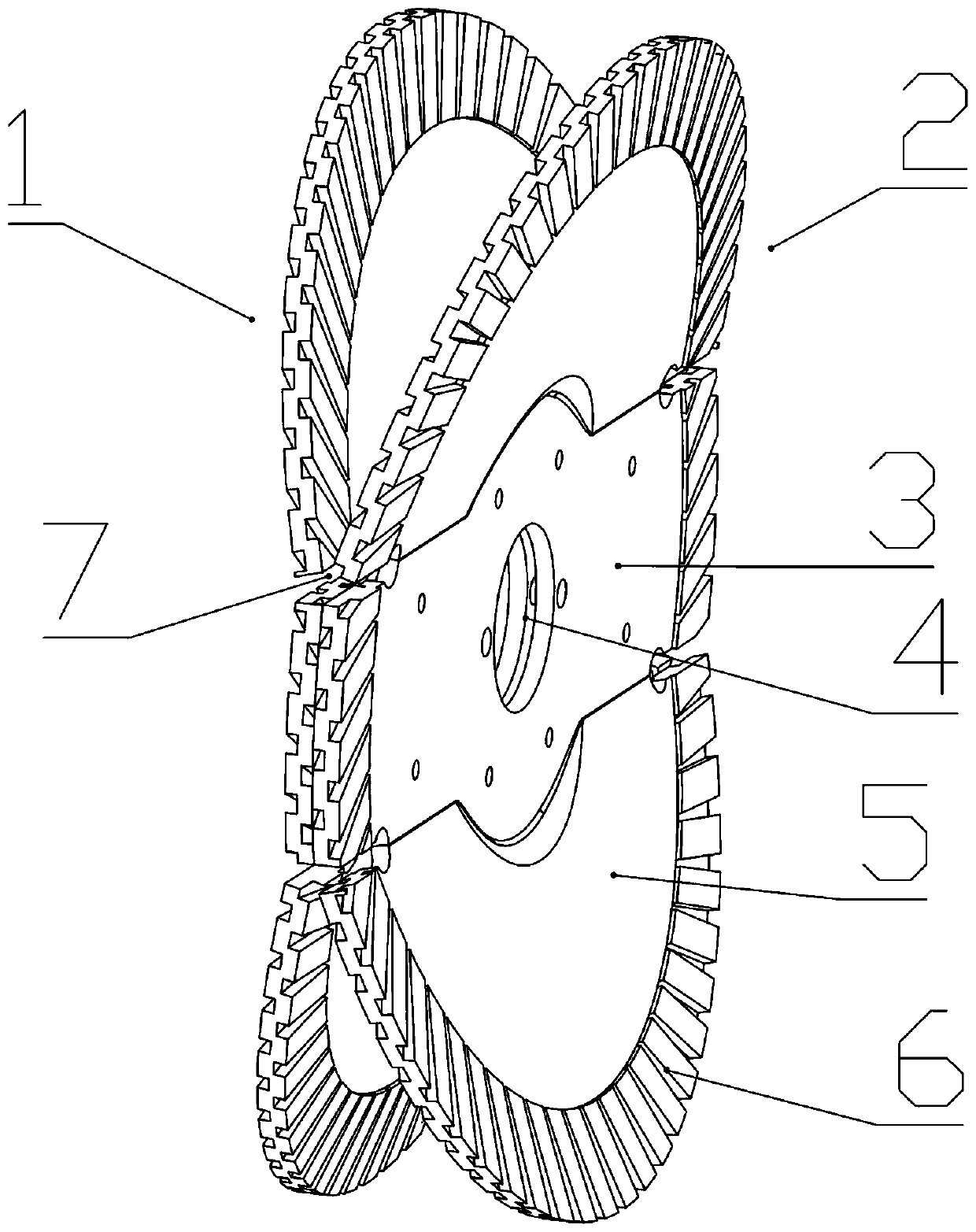

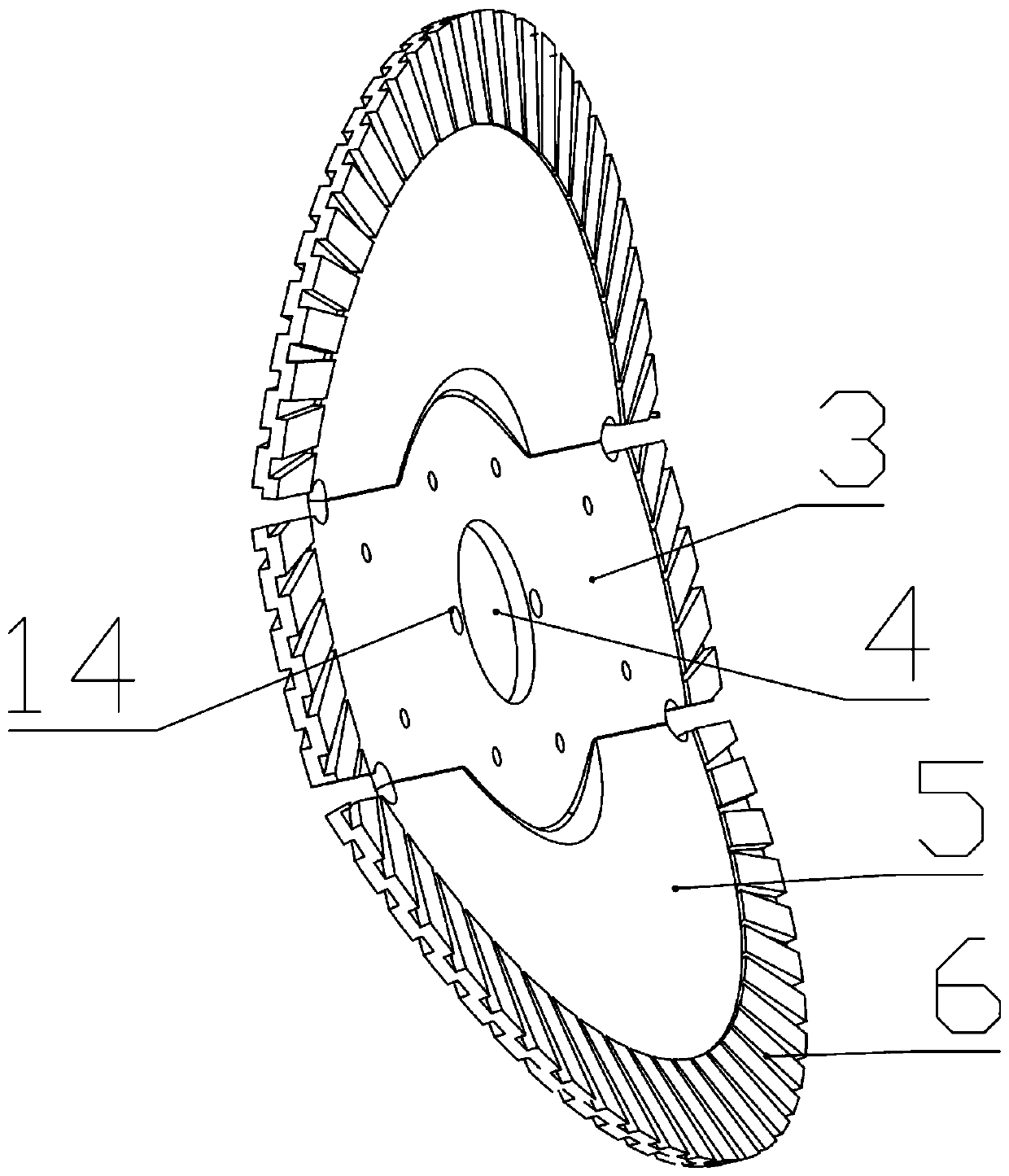

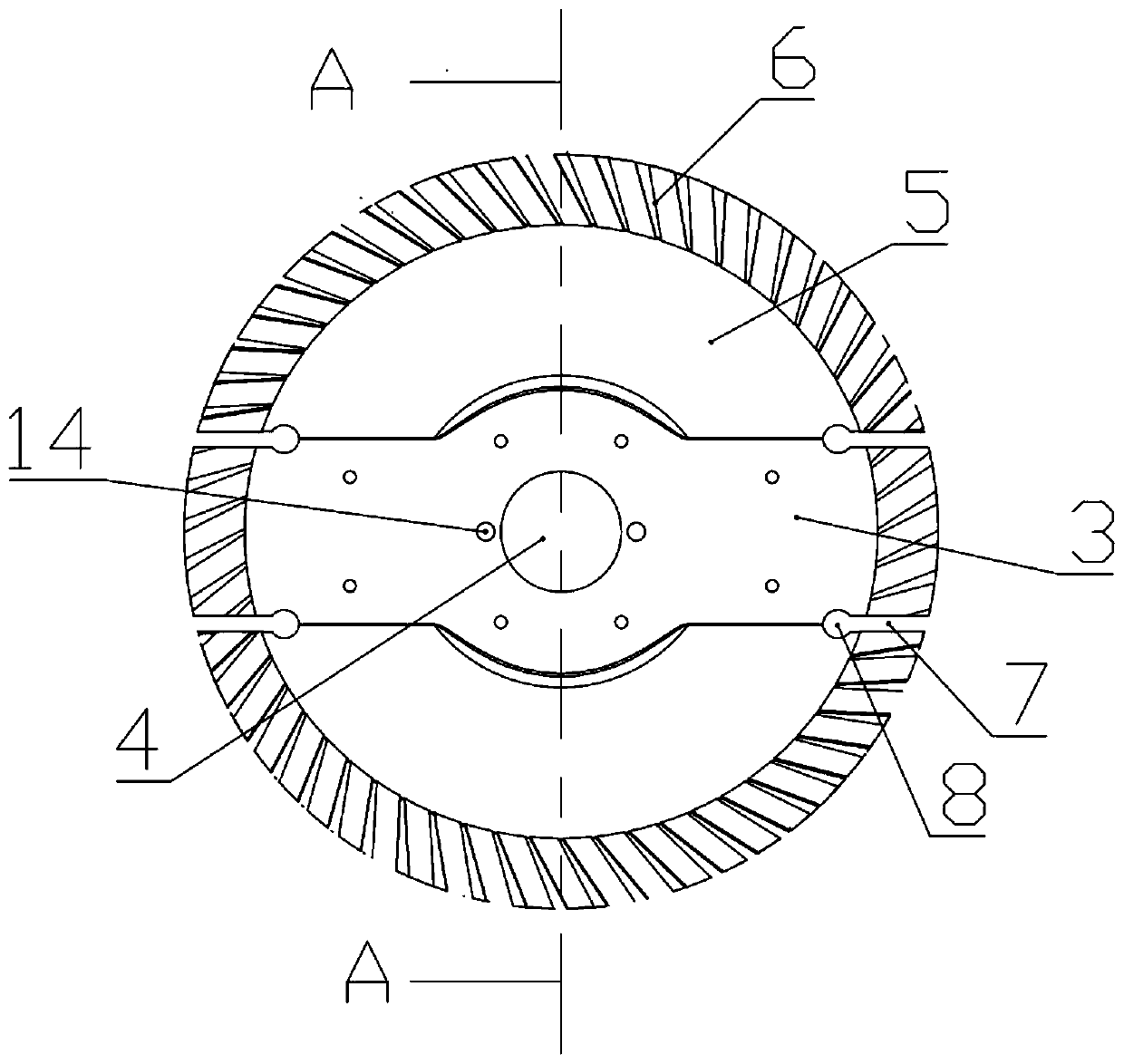

[0043] A slotted saw blade without gaps, comprising two fixed left saw blades 1 and right saw blades 1;

[0044] The left saw blade 1 and the right saw blade 1 include a base part 3, the middle part of the base part 3 is provided with a saw blade installation hole 4, and both sides of the base part 3 are bent to form an inclined part 5, and the inclined part 5 faces the base body. One or both sides of part 3 are arranged obliquely;

[0045] Edges of the base portion 3 and the inclined portion 5 are both provided with a cutting head 6 .

[0046] In this embodiment, the inclined parts 5 on both sides of the base part 3 are inclined to the same side, and the cross-sectional shape of the left saw blade 1 or the right saw blade 1 is "C" shape. The saw blade is bent symmetrically, and the bending angle is generally not greater than 15°.

[0047] In this embodiment, cutting grooves 7 are formed on the edges of the left saw blade 1 and the right saw blade 1 , and crack-relief holes ...

Embodiment 2

[0052] A gap-free saw blade, comprising a first saw blade 9 and a second saw blade 10 intersecting each other, the first saw blade 9 and the second saw blade 10 are provided with intersecting grooves 11, the first saw blade 9 The first saw blade 9 and the second saw blade 10 are intersected with each other through the intersecting groove 11 , and there is an included angle between the first saw blade 9 and the second saw blade 10 .

[0053]The present invention also has another combination scheme for cutting saw blades, including a first saw blade 9 and a second saw blade 10 that can be arranged crosswise, and both the first saw blade 9 and the second saw blade 10 are provided with intersecting grooves 11, The two saw blades are oppositely inserted together through the intersecting groove 11, the first saw blade 9 and the second saw blade 10 are arranged obliquely relative to each other, and the cross-sectional shape of the first saw blade 9 and the second saw blade 10 is also ...

Embodiment 3

[0060] A sawtooth saw blade, comprising a base part 3 and several arc-shaped plates 21 located on the peripheral side of the base part, arc-shaped cutter heads 22 are arranged at the edges of the arc-shaped plates 21, and the arc-shaped plates 21 are opposite to the base part 3. Oblique setting, the inclination angles of several arc-shaped plates 21 are the same. Preferably, the number of curved plates 21 is eight. When carrying out the slotting operation, the rotation of the base part 3 drives the arc-shaped plate 21 on the edge of the base part 3 to rotate. Because the arc-shaped plate 21 is arranged obliquely, the sawtooth saw blade can cut to a wider range when cutting. The cutting efficiency is high, and when multiple pieces are used side by side on the slotting machine, the cutting space of the cutter head of the two saw blades can also be connected, and there is no cutting gap between the saw blades, so that it can be formed at one time during cutting, without Cut mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com