Rotor pressing wheel adjusting mechanism applied to rotor spinning

A technology of adjusting mechanism and pressing wheel, applied in spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the problems of breakage, deformation of adjustment piece, affecting the normal use of bolts, etc. Small torque, prolong service life, ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

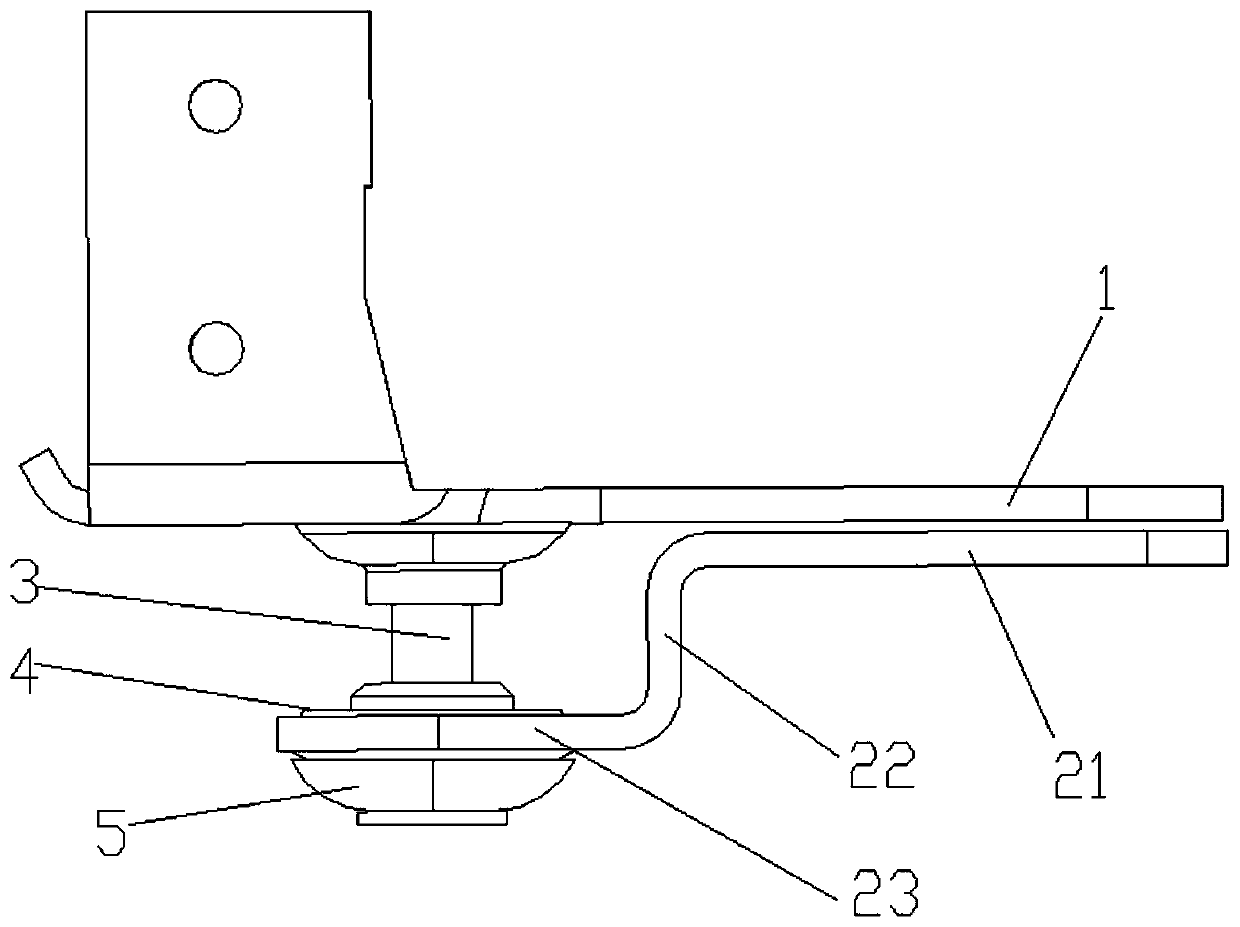

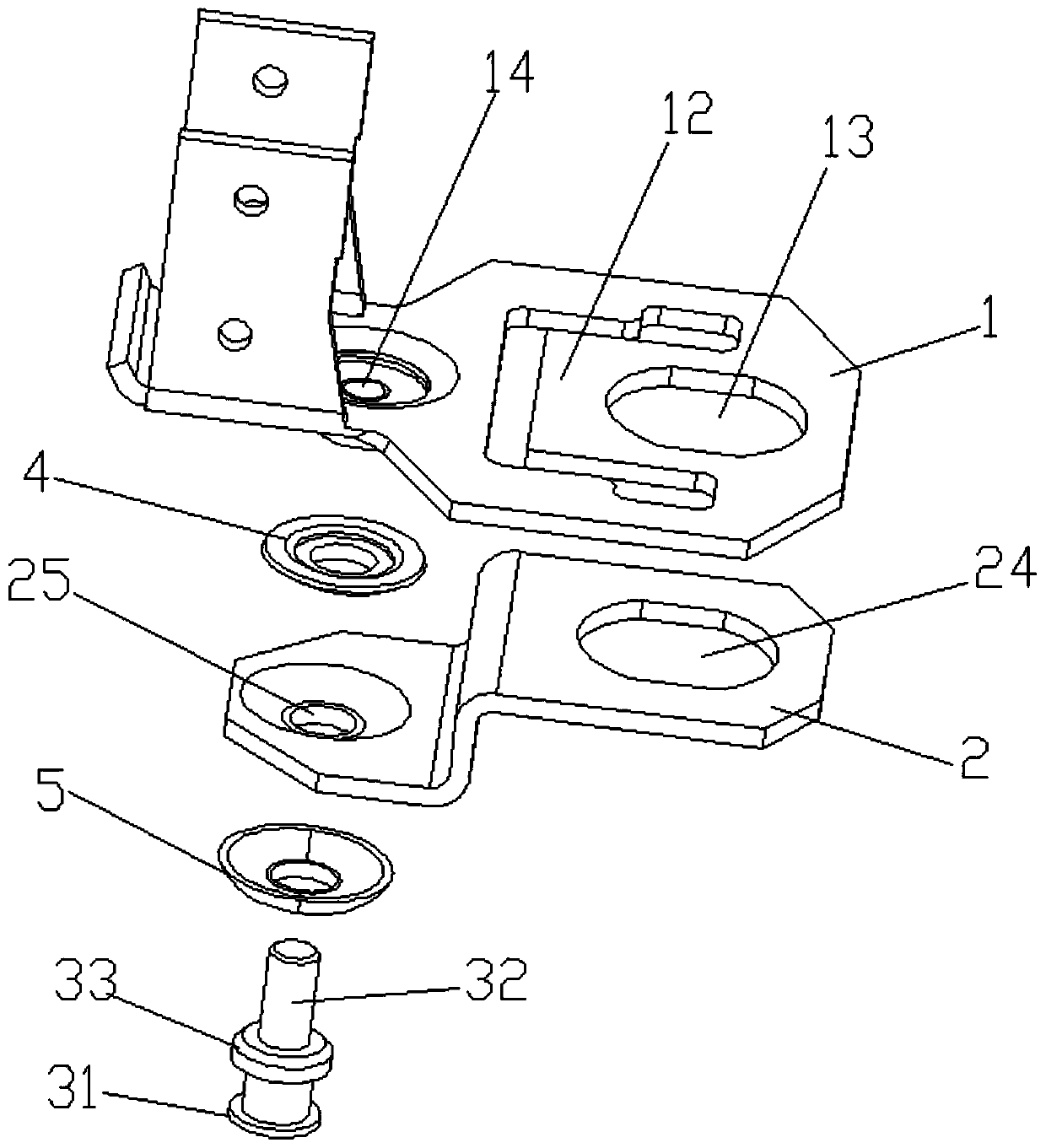

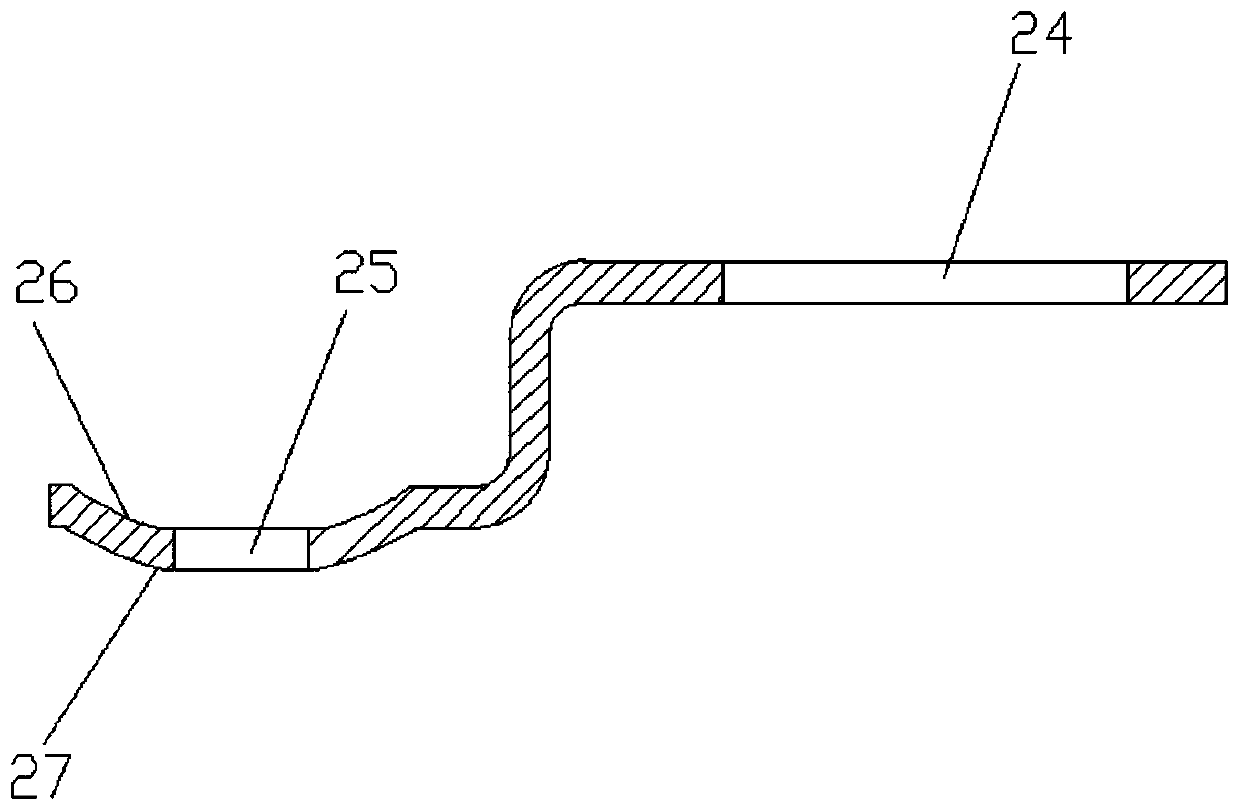

[0021] Embodiment: a kind of rotor pinch wheel adjustment mechanism applied on air spinning, such as Figure 1-4 As shown, it includes a pressure wheel mounting plate 1, an adjustment piece 2, and an adjusting bolt assembly, wherein the pressure wheel mounting plate 1 is provided with a U-shaped through hole 11 that opens outward (shown to the right in the figure), so that the U-shaped through hole 11. An overhanging pressure roller installation part 12 is formed in the inner cavity, and the pressure roller installation part 12 can be bent and deformed at a certain angle under the action of a certain force.

[0022] In this embodiment, as a preference, both sides of the U-shaped through-hole 11 are extended to the outside with relief openings 15, so that the part of the pressure wheel mounting plate 1 located outside the U-shaped through-hole 11 is more easily deformed under force, reducing the pressure. The amount of force required for small angle adjustments.

[0023] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com