Variable guide rail support structure resistant to three-dimensional movement and deformation

A three-dimensional moving and supporting structure technology, applied in the direction of building maintenance, building structure, building type, etc., can solve the problems of stress damage, structural damage of support mechanism, increase in production cost of enterprises, etc., to improve the resistance to three-dimensional mining deformation. capacity, reduce material waste, and save total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

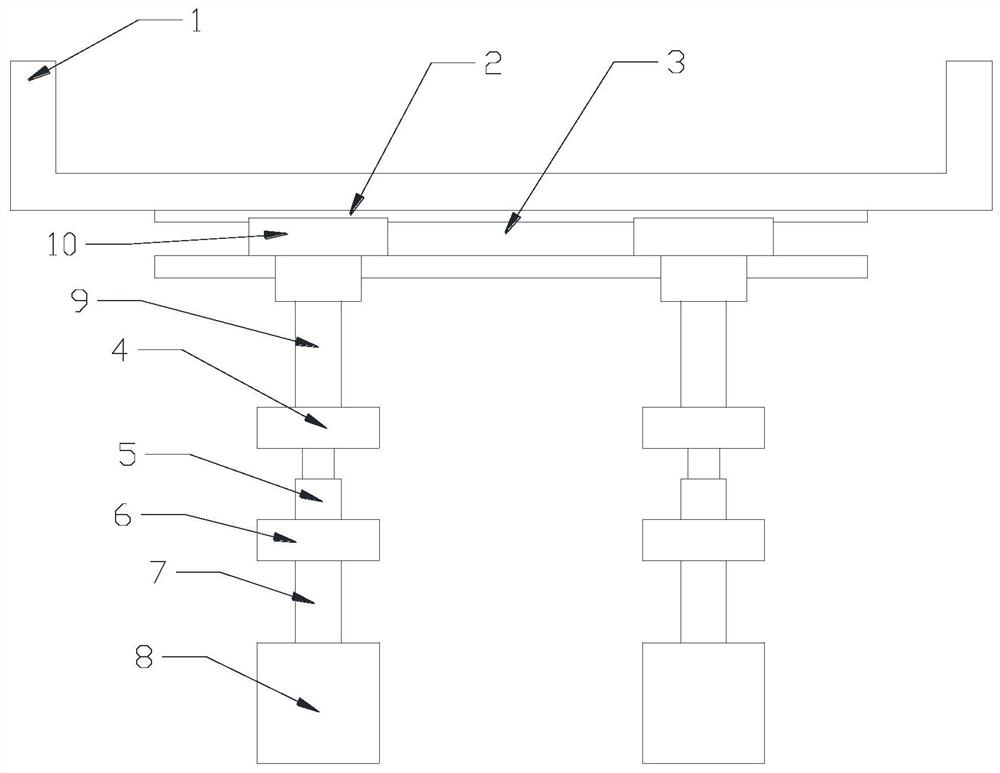

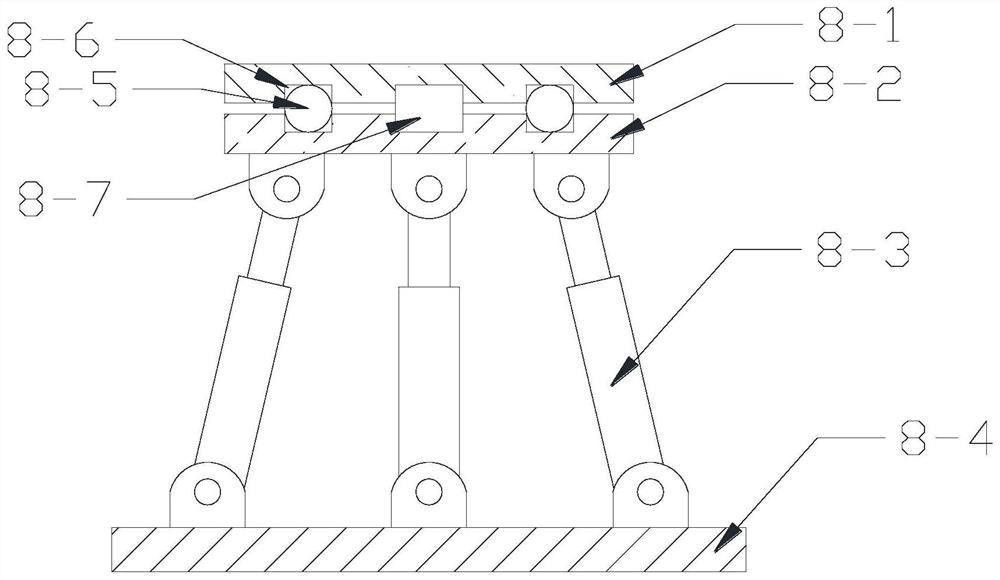

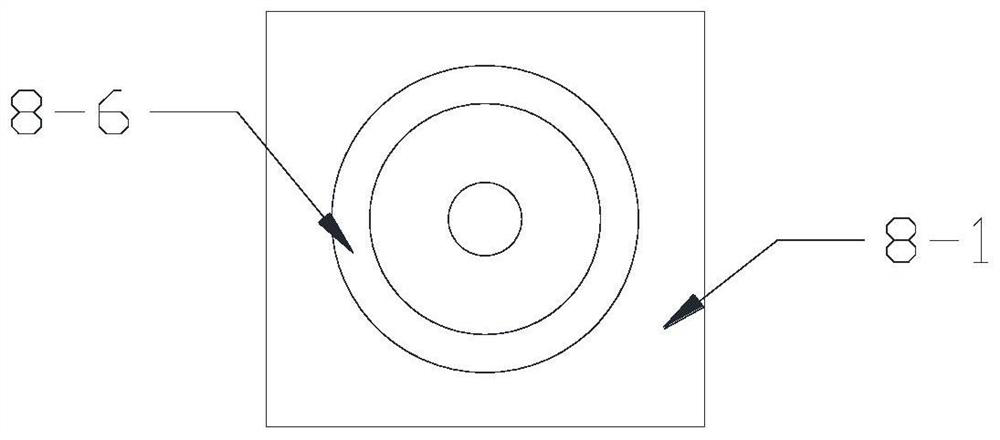

[0020] like figure 1 As shown, the anti-three-dimensional movement deformation variable guide rail support structure of the present invention includes a U-shaped support beam 1, a load-carrying beam 2 and a variable-direction support unit anti-three-dimensional movement deformation, and the supporting frame of the protected building passes through the U The girder 1 is connected to the load-bearing beam 2, and the load-bearing beam 2 is slidably connected to the upper end of the variable direction support unit that resists three-dimensional movement and deformation; when underground coal mining causes ground movement and deformation, the three-dimensional movement and deformation resistance The upper end of the variable direction support unit moves freely along the transverse guide rail 3 on the lower surface of the load beam 2; when the stratum of the protected building is deformed due to the mining of the coal mine below the protected building, the anti-three-dimensional move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com