Guide wheel type yarn sensor based on force sensor and rotating speed sensor

A speed sensor and sensor technology, applied in textiles and papermaking, etc., can solve the problems affecting the normal use and quality of yarns, and the number of strands is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

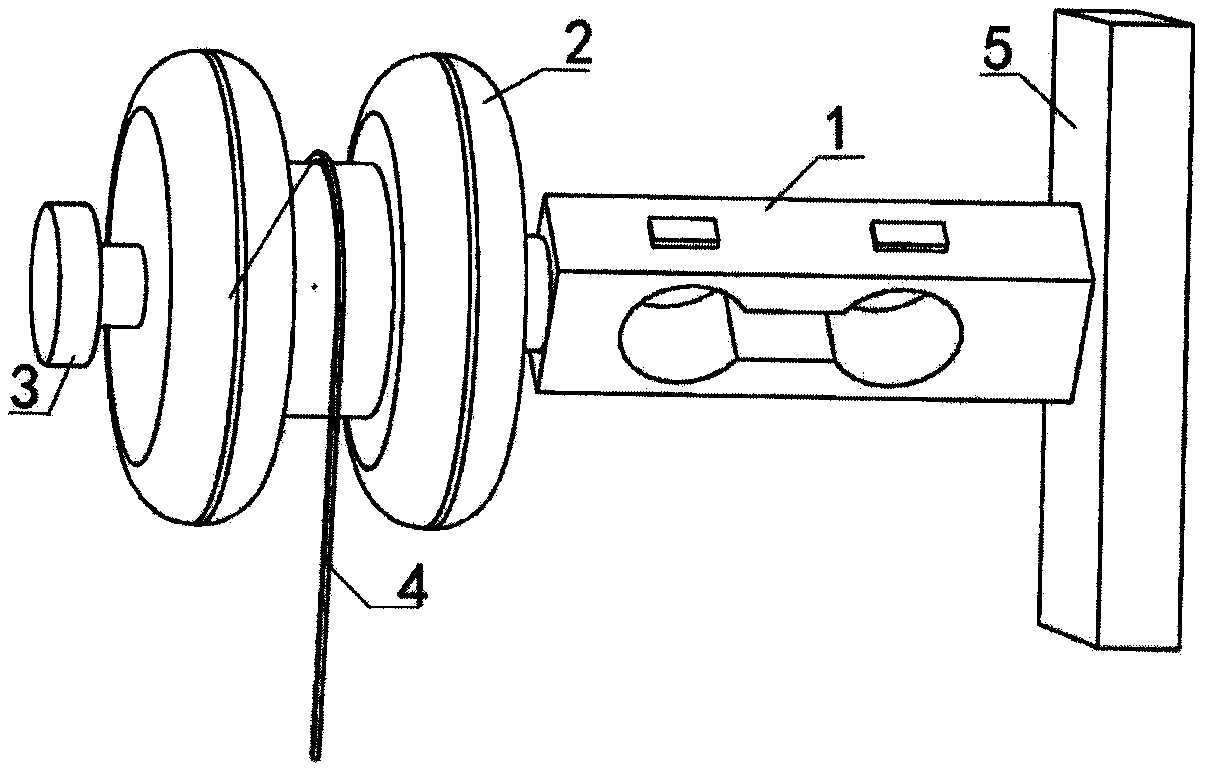

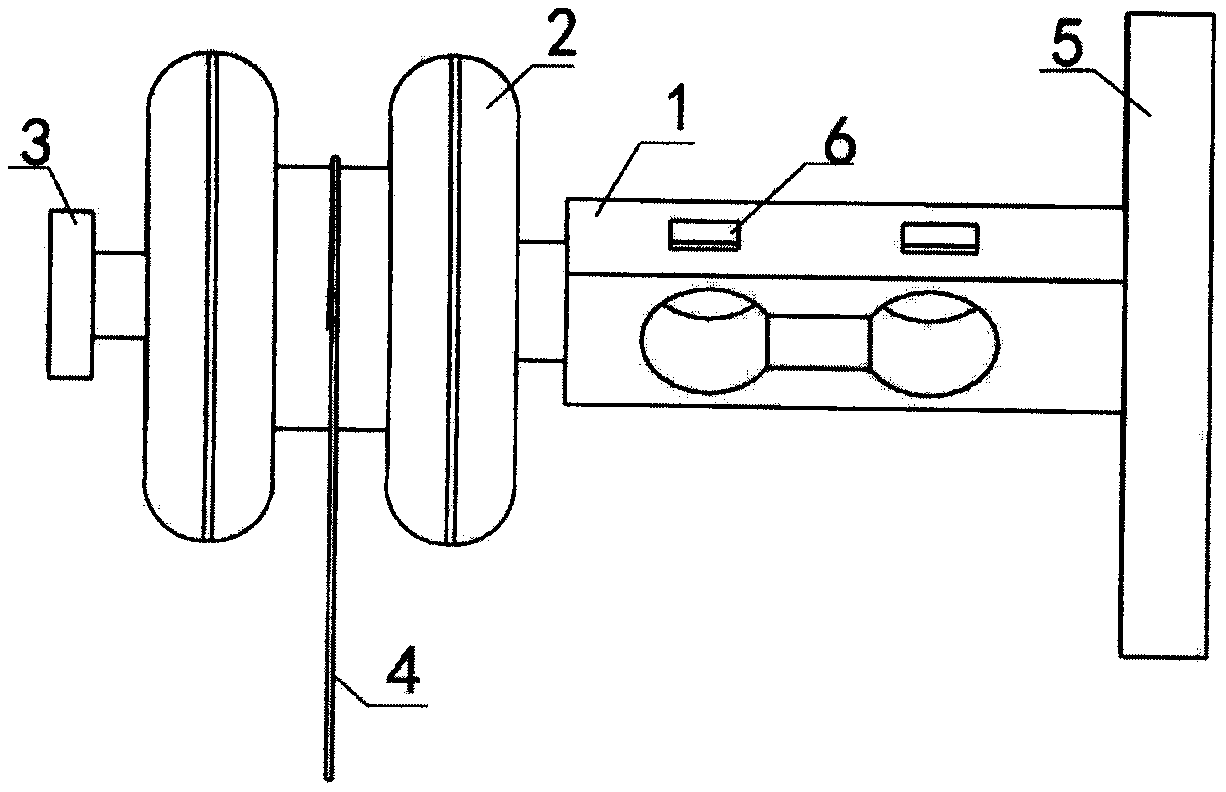

[0017] Next, with reference to the accompanying drawings, a guide wheel sensor based on the combination of a force-sensitive sensor and a rotational speed sensor of the present invention will be described in detail.

[0018] A guide wheel sensor based on the combination of a force sensitive sensor and a rotational speed sensor proposed by the present invention is as follows: figure 1 As shown, it includes a force sensor 1, a roller 2, and a speed sensor 3; the specific installation method is that the force sensor 1, the speed sensor 3 and the roller 2 are integrated on a sensing shaft, and the three are connected to form a guide wheel sensor , while the sensing shaft is fixed on the support 5 in the form of a cantilever beam.

[0019] The guide wheel sensor can measure the tension of the thread on the roller to determine whether the thread is disconnected. The detection and judgment method includes the following steps:

[0020] Step A, the roller 2 is wound with a silk thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com