Porous emitter needle infiltration device and method

An infiltration device and a technology of launching needles, which are applied in the field of electric propulsion, can solve problems such as the infiltration of inapplicable porous launching needles, and achieve the effect of high-efficiency infiltration and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

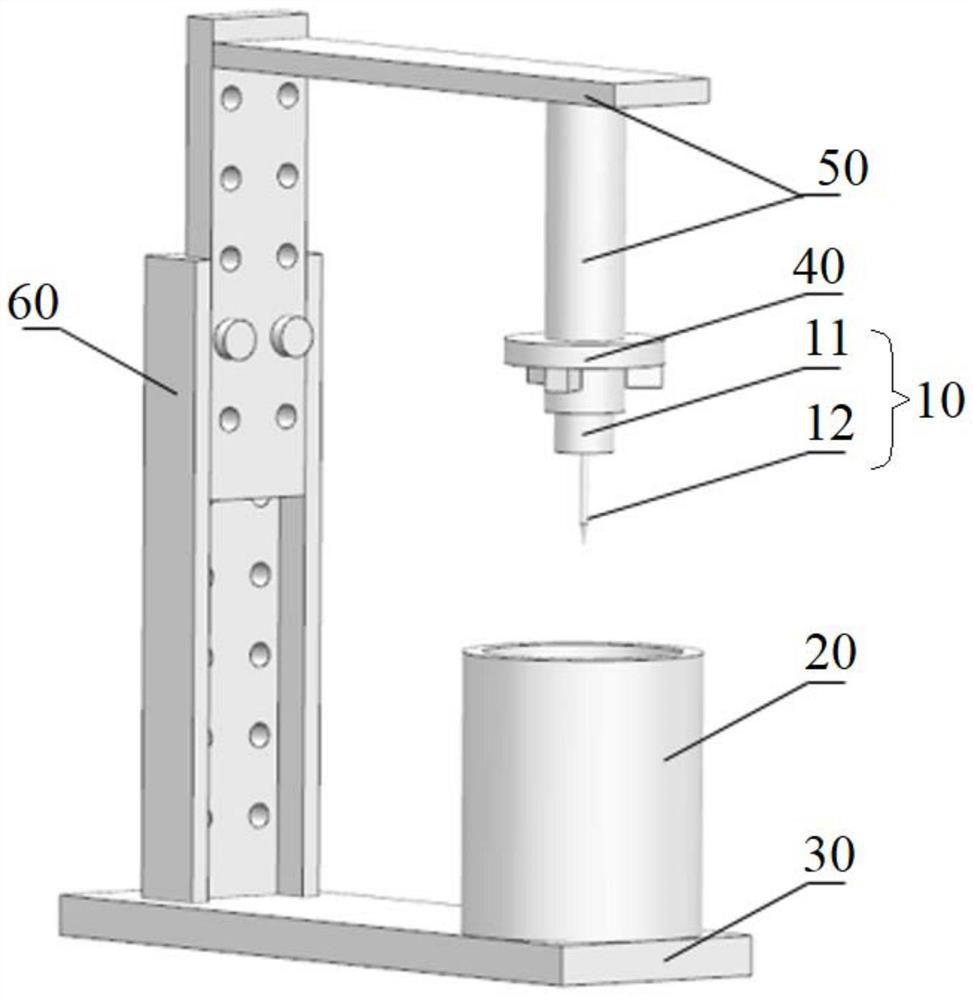

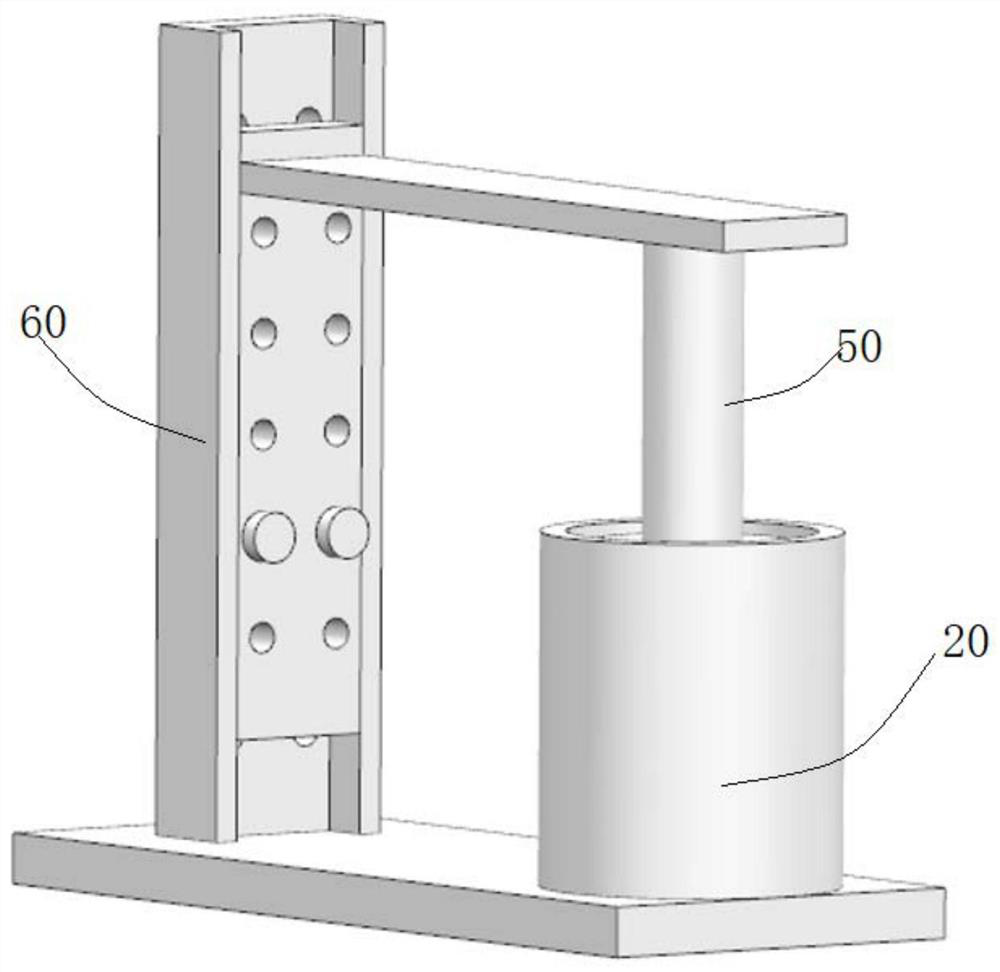

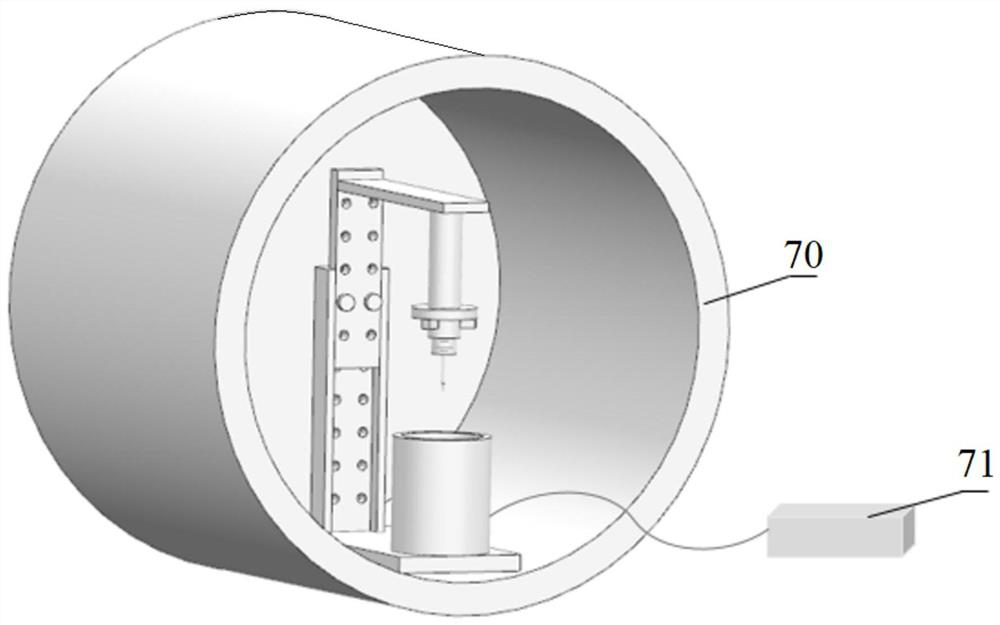

Embodiment 1

[0042]This embodiment provides a porous emission needle infiltration device, such as Figure 1~2 As shown, the porous emitting needle infiltration device includes an infiltration module 10 and a heating device 20 arranged vertically opposite to each other, wherein: the infiltration module 10 is configured to be able to move up and down relative to the heating device 20 to be in the first infiltration state, the second wetting state, or the third wetting state; the wetting module 10 includes a storage chamber 11 and a porous emission needle 12 that are coaxial and sequentially connected from top to bottom, and a solid state that is accommodated in the storage chamber 11 propellant; the first wetted state is as figure 1 As shown, it includes: the wetting module 10 is completely suspended above the heating device 20, and the pores of the porous emitting needles 12 are penetrated; the second wetting state is as follows figure 2 As shown, it includes: the infiltration module 10 i...

Embodiment 2

[0048] This embodiment provides an infiltration method for porous emission needles, the method includes: arranging the infiltration module 10 and the heating device 20 vertically opposite each other; the infiltration module 10 moves up and down relative to the heating device 20, To be in the first wetting state, the second wetting state or the third wetting state; the storage chamber 11 and the porous emission needle 12 of the wetting module 10 are connected coaxially and sequentially from top to bottom, and the solid propellant is placed in In the storage chamber 11; the first wetting state includes: the wetting module 10 is completely suspended above the heating device 20, and the pores of the porous emitting needles 12 penetrate; the second wetting state includes: the The wetting module 10 is completely submerged in the heating device 20, the heating device 20 is turned on, the propellant melts and flows into the pores of the porous emission needle 12 through gravity and cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com