Automatic plug tray feeding infiltration seeding device

A technology of automatic feeding and plug tray, applied in the fields of botanical equipment and methods, soilless culture, cultivation, etc., can solve the problems of low work efficiency, less automation equipment, manual operation, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

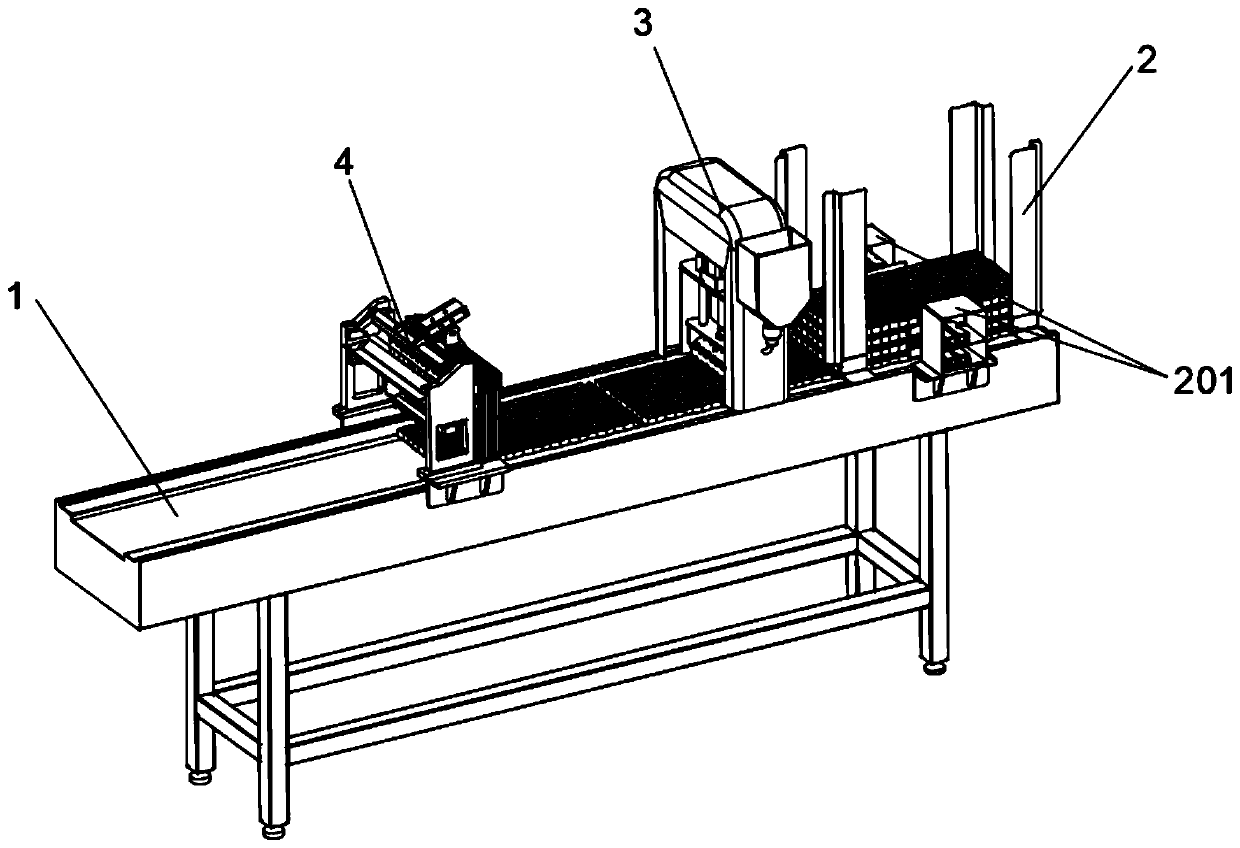

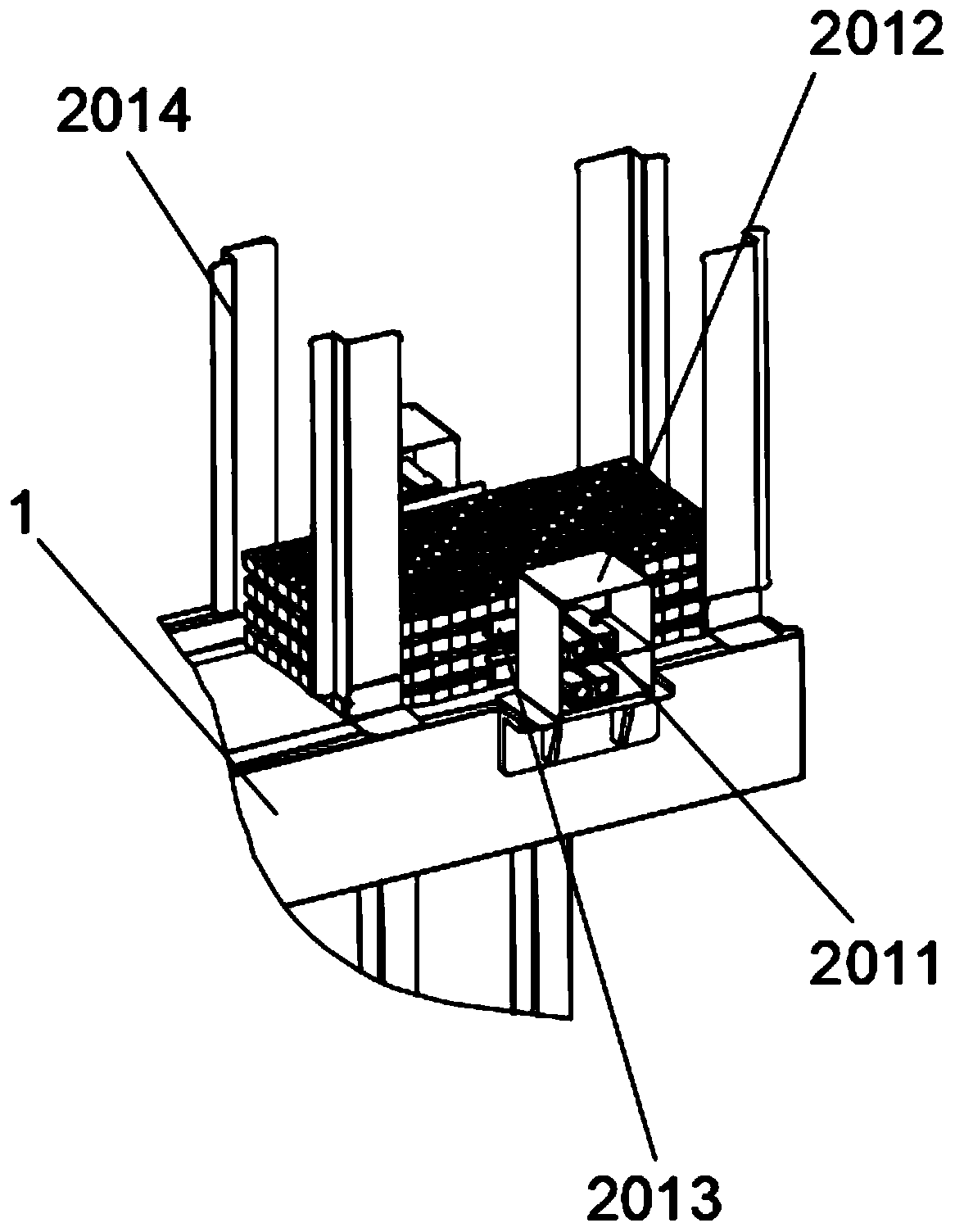

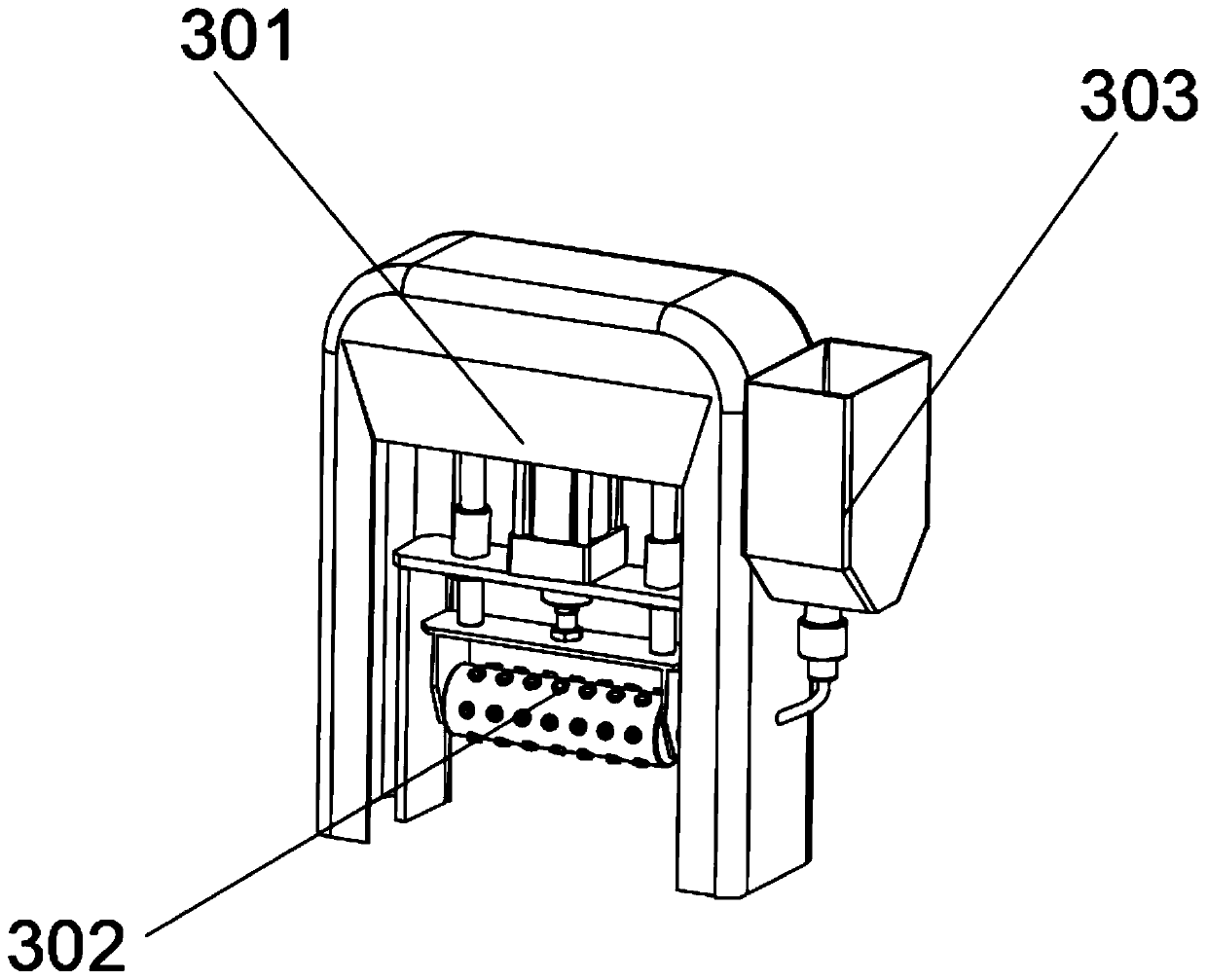

[0027] see Figure 1-Figure 7 , the present embodiment is a kind of automatic tray feeding infiltration sowing equipment, comprising a belt conveyor line 1, and the belt conveyor line 1 is sequentially provided with a guide wheel type for inserting its seeds on the sponge seedling tray along the opposite direction of transmission. The seed-suction and planting device 4, the sponge rolling water injection device 3 that soaks the sponge seedling tray and the sponge seedling tray automatic feeding device 2 that makes the stacked sponge seedling trays automatically and separately placed on the belt conveyor line 1. Specifically, the belt conveyor line 1 is composed of a movable support frame and a belt conveyor fixed on the movable suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com