Data enhancement method and system for PCB image defect detection

A PCB board and defect detection technology, which is applied in the field of image recognition, can solve the problems of data enhancement of small-sized missing image samples, inaccurate PCB board image defects, etc., and achieve the effect of enhancing generalization ability, easy detection, and enhancing training data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

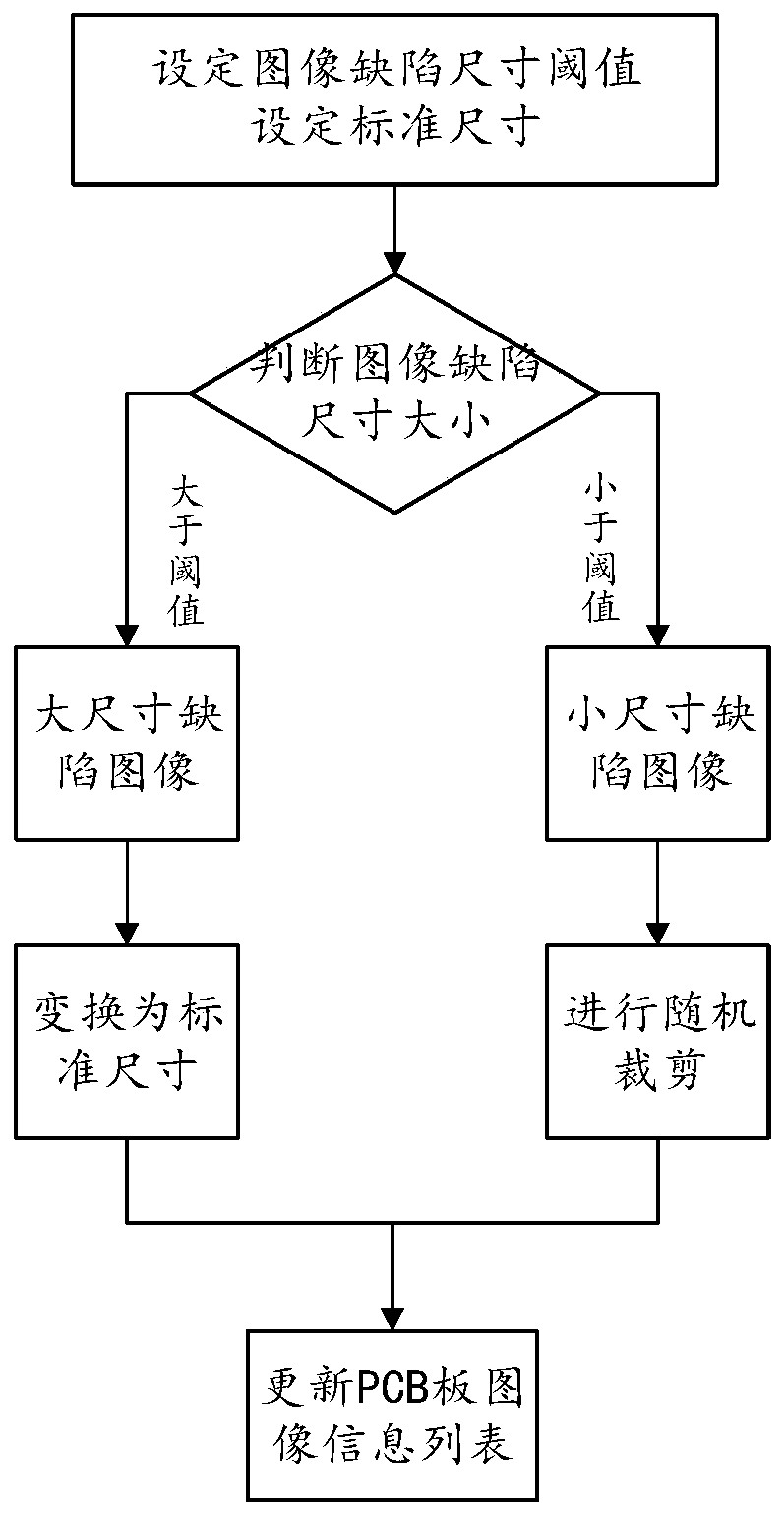

[0045] This embodiment proposes a method for randomly cropping crops for PCB board image defects. This method is applied in the deep learning model training process to enhance data and make it easier to detect small defects in the image. Such as figure 1 shown.

[0046] The steps that this embodiment realizes are as follows:

[0047] Step 1: Set the threshold threshold of the defect size, and judge whether the defect in the image is a large-size defect according to the defect bbox information in the list results of the image information stored on the PCB board. If it is larger than the threshold, it is a large-size defect, otherwise, it is a small-size defect;

[0048] Step 2: If the defect is determined to be a large-size defect in step 1, directly resize the image to crop_size, and update the image matrix, image size, defect bbox and other information in the results list at the same time;

[0049] Step 3: If it is judged in step 1 that the defect is a small-sized defect, c...

Embodiment 2

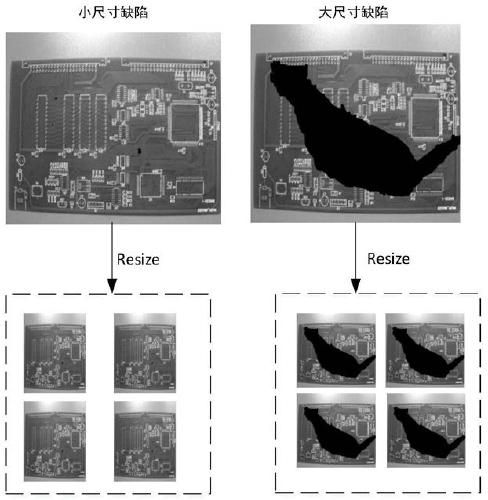

[0064] The applicable scenario of this implementation is defect detection in the PCB panel industry. In order to find the position of the foreign matter in the PCB picture, and classify whether it is a foreign matter or other defect types. The commonly used methods are resize (image scaling) and crop (cropping). The following explains the specific operations of resize and crop and compares the test results:

[0065] 1. The resize method

[0066] Due to the requirements of hardware equipment and computing speed, we generally have to scale the actual picture. Such as figure 2 As shown, no matter what the zoom ratio is, for large-sized defects, zooming has little effect on its detection; for small defects, as the zoom ratio increases, the detection of small defects in the picture becomes more and more difficult, so for the images that exist In the case of small defects, it cannot be resized, and the crop method needs to be adopted.

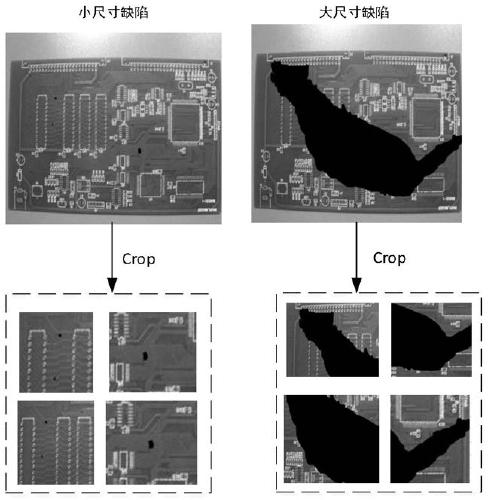

[0067] 2. crop method

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com