Synchronous lifting mechanism and ultrasonic cleaning machine applying same

A technology of synchronous lifting and lifting frame, applied in the field of lifting machinery, can solve the problems such as affecting the translation and lifting of the translation mechanism, the inability of multiple lifting cylinders to maintain synchronization, and affecting the working efficiency of the ultrasonic cleaning machine, etc., to achieve the effect of ensuring the working efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

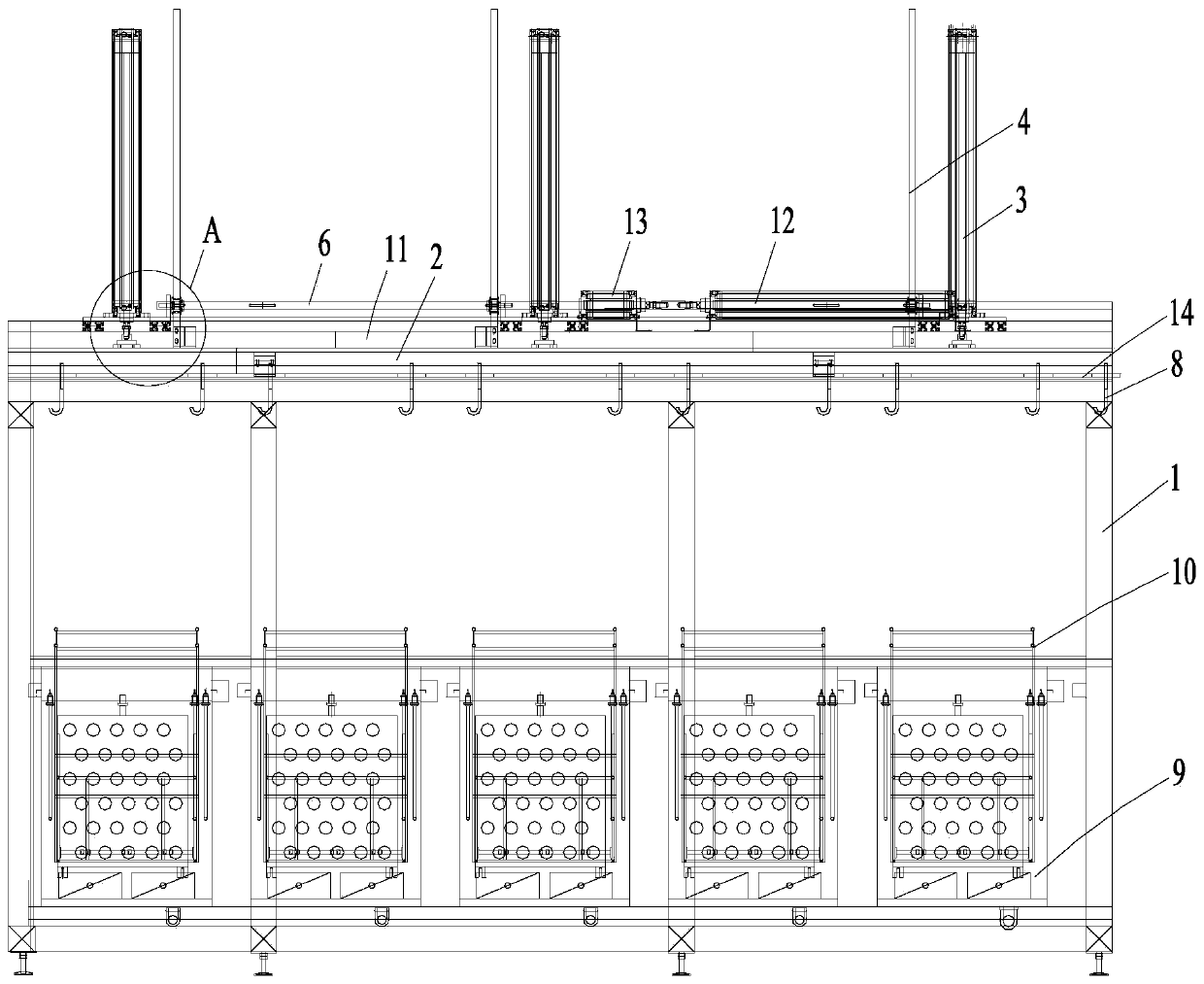

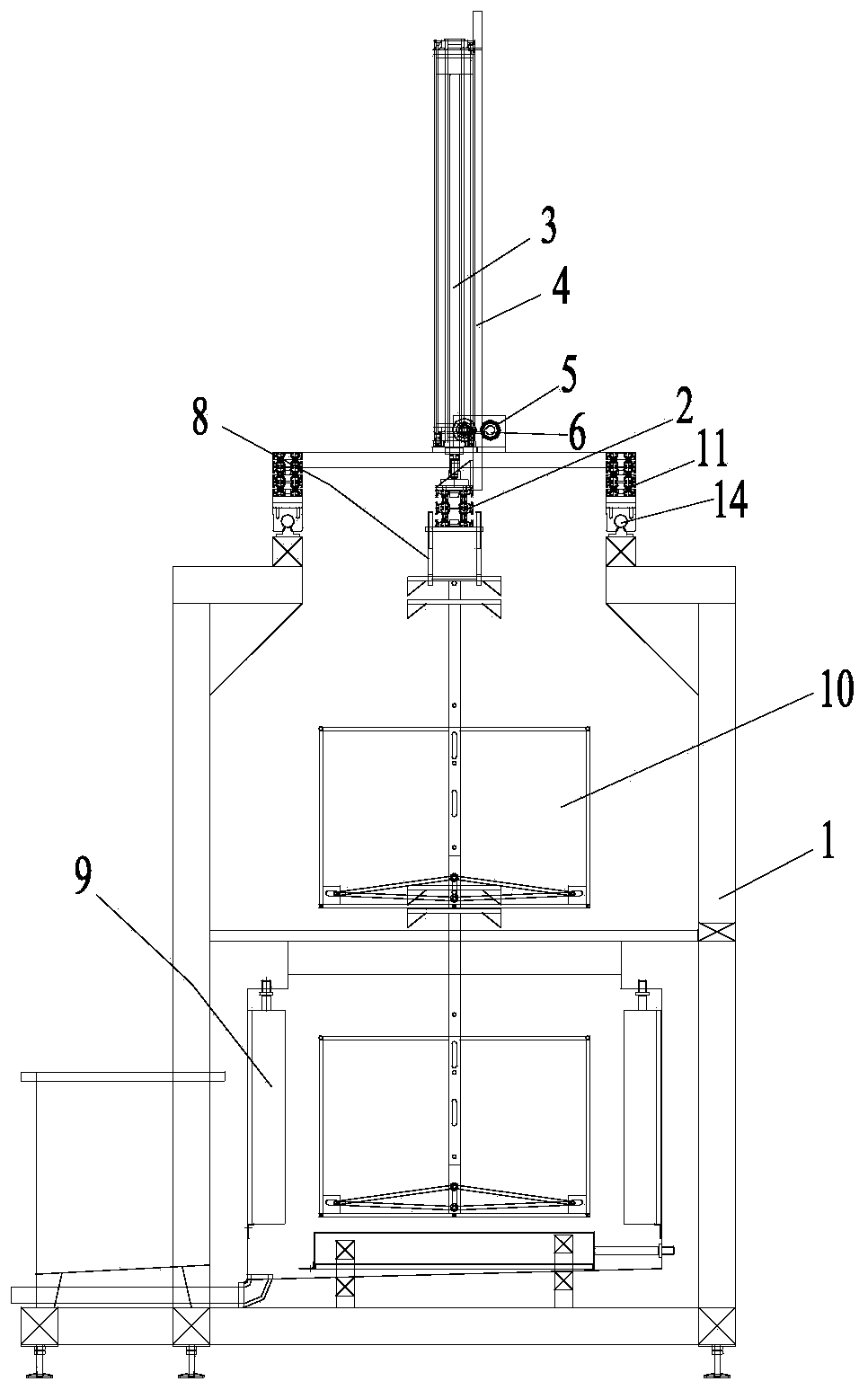

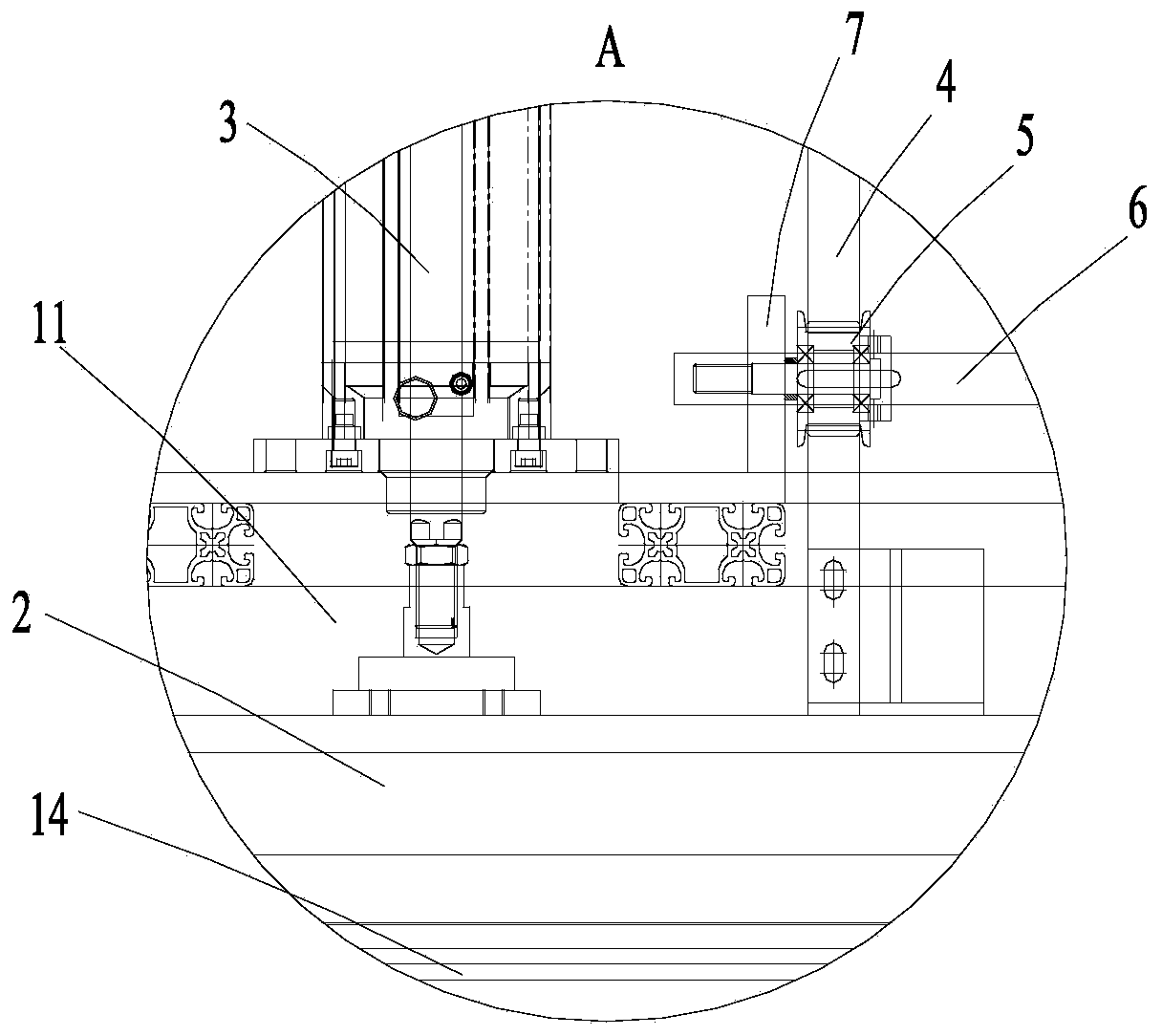

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] The invention relates to the improvement of the lifting mechanism of the ultrasonic cleaning machine to solve the problem that the current lifting mechanism cannot realize synchronous lifting. The improved lifting mechanism, through the cooperation of gears, racks and connecting rods, when the lifting frame is raised and lowered, multiple gears connected to the same connecting rod can ensure synchronous lifting between multiple racks meshing with it, and the gears The bar is connected with the lifting frame, so that it can ensure the synchronous lifting of each part of the lifting frame, and then realize the synchronous lifting of multiple cleaning frames mounted on the lifting frame, ensuring the working efficiency of the ultrasonic cleaning machine.

[0023] Such as Figure 1-3 As shown, an ultrasonic cleaning machine is shown, inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com