Intelligent water pumping experiment system

A pumping test, intelligent technology, applied in control/regulation systems, material inspection products, non-electric variable control, etc., can solve problems such as failure to successfully complete the pumping test, weak performance of the pump screen and pump, affecting the service life of the pump, etc. Achieve rich and accurate hydrogeological parameters, reduce the difficulty of pump lifting, and achieve the effects of precise automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

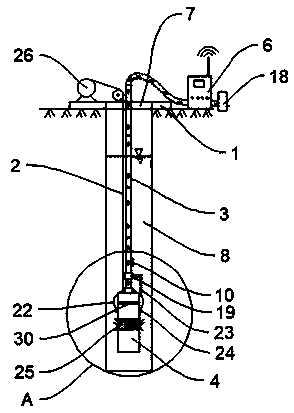

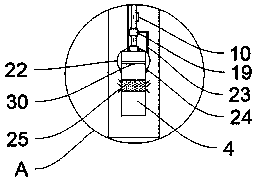

[0030] Such as Figure 1-Figure 5 As shown, the present embodiment provides an intelligent water pumping experiment system, including an installation substrate 1, a steel wire rope 2, a water pipe 3, a water pump 4, a liquid level gauge, a water pump cable 5, a liquid level gauge cable, and a control box 6. There are through holes 7, and the through holes 7 are facing the wellhead of the drilling well 8. The installation base plate 1 is provided with a lifting mechanism capable of controlling the synchronous lifting of the steel wire rope 2, water pipe 3, water pump cable 5 and liquid level gauge cable; the steel wire rope 2, water pipe 3 and water pump cable 5. One end extending into the well 8 through the through hole 7 is connected to the water pump 4 in the well 8, and the end of the liquid level gauge cable extending into the well 8 through the through hole 7 is connected to the liquid level gauge in the well 8. , the other end of the steel wire rope 2 is fixedly connecte...

Embodiment 2

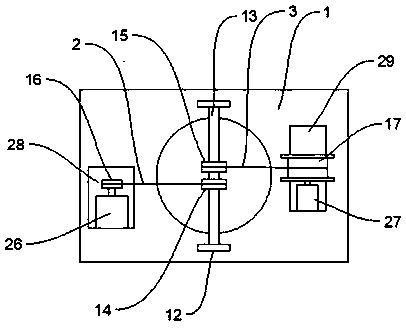

[0034] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

[0035] Lifting mechanism comprises installation frame 12, steel wire rope rewinding device and water pipe rewinding device, and installation frame 12 is provided with connecting shaft 13, is connected with pulley one 14 and pulley two 15 in rotation on connecting shaft 13, and pulley one 14 and pulley two 15 are equal to each other. Located above the through hole 7, the wire rope winding device includes a wire rope winch 16 arranged on the installation base plate 1 for winding the wire rope 2. One end of the wire rope is fixedly connected to the wire rope winch, and the other end goes around the pulley 14 and is located in the drilling well 8. The water pump 4 is connected, and the water pipe winding device includes a water pipe winch 17 installed on the installation base plate 1 for winding the water pipe 3, the water pump cable 5 and the water level gauge cable 11. When the wat...

Embodiment 3

[0038] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 2.

[0039] In order to facilitate the synchronous lifting operation of the water pump cable 5, the water level gauge cable 11 and the water pipe 3, the water pump cable 5 and the water level gauge cable 11 are all fixed on the outside of the water pipe 3 by binding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com