Microwave plasma vapor phase epitaxy deposition equipment with lifting device

A microwave plasma and vapor phase epitaxy technology, applied in electrical components, gaseous chemical plating, coatings, etc., can solve the problems of microwave difficulties, limited cavity operation space, inconvenient maintenance of substrate equipment, etc., to reduce the probability of errors, Simple operation and improved operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

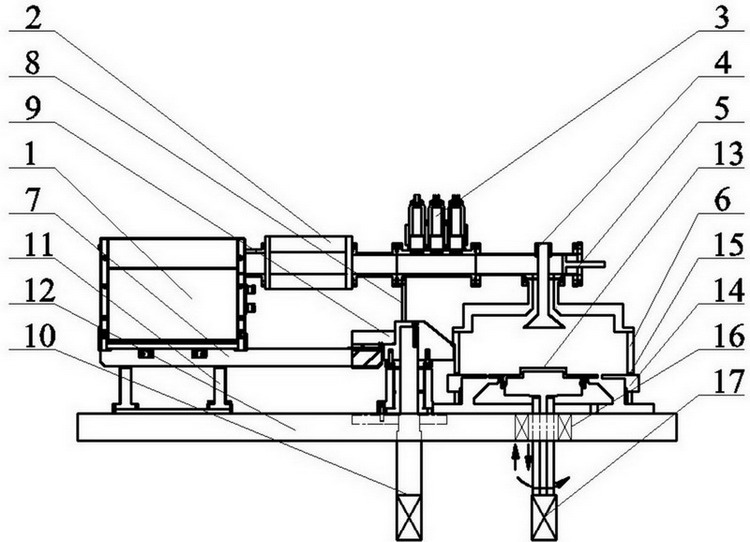

[0010] Embodiment 1: refer to figure 1 , a microwave plasma vapor phase epitaxy deposition equipment with a lifting device provided by the present invention is mainly composed of a microwave transmission system, an upper cavity 6, a transmission system support table connector 9, a lifting push rod and a motor 10, and a working platform 12. The lower cavity 14 and the substrate stage 13 are composed, wherein the microwave transmission system is composed of a microwave source 1, a coupler 2, a three-axis matcher 3, a mode converter 4 and a short circuit 5, which are sequentially fixedly connected, wherein the microwave is transmitted through the microwave The system is coupled from the top of the upper chamber 6 into the working chamber composed of the upper chamber 6 and the lower chamber 14. The microwave transmission system is fixedly connected to the upper chamber 6 through the mode converter 4. The transmission system under the three-axis matcher 3 The support platform conn...

Embodiment 2

[0011] Embodiment 2: refer to figure 1 , on the basis of Embodiment 1, the microwave source support table 7 and the working platform 12 are connected by a gas spring 11 to play a balancing role in motion buffering. The gas spring 11 can also be a cylinder or an electric screw rod or other active driving mechanism , to balance the difference in the left and right lever forces of the movement.

Embodiment 3

[0012] Embodiment 3: refer to figure 1 , on the basis of Embodiment 1, the upper chamber 6 and the lower chamber 14 are provided with a sealing ring 15, when the upper chamber falls, the lifting push rod and the motor 10 apply the contact pressure between the upper and lower chambers through the reverse rotation of the motor , to achieve enhanced sealing performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com