Forest land weeding equipment for camellia oleifera planting

A kind of weeding equipment and woodland technology, which is applied in the field of woodland weeding equipment for camellia oleifera planting, can solve the problems of being buried under the ground, unable to effectively cut off the roots, and increase the workload of weeding, so as to improve the precision, achieve better and more thorough weeding effect, The effect of preventing regermination of new shoots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

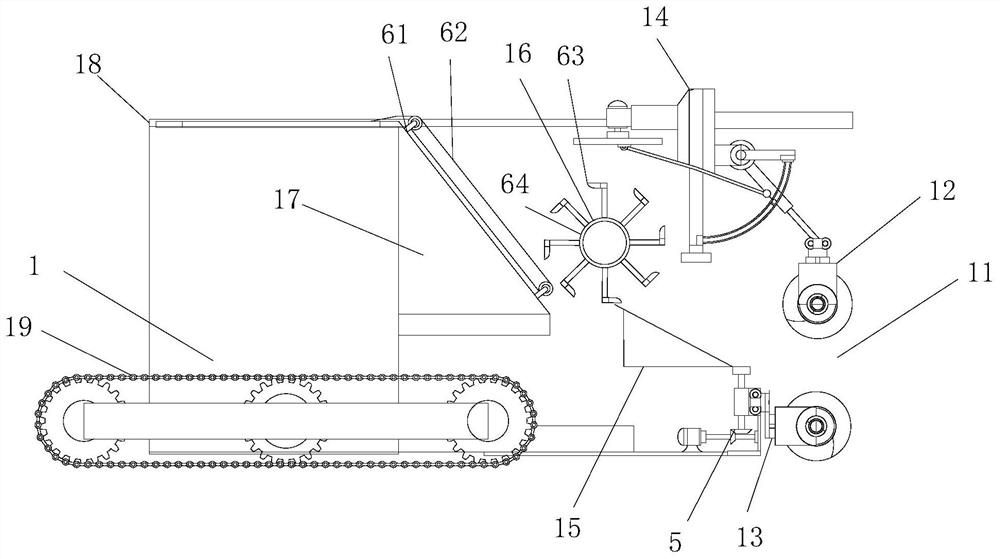

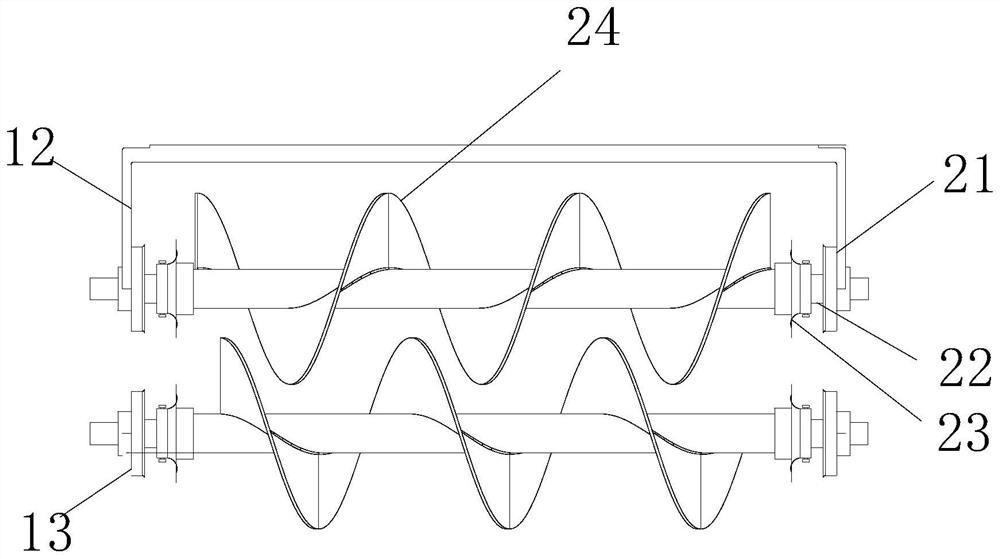

[0028] see Figure 1~3 , a woodland weeding equipment for Camellia oleifera planting, comprising a weeding machine 1, the front side of the weeding machine 1 is provided with a weeding port 11, and the upper and lower sides of the weeding port 11 are respectively provided with an upper weeding frame 12 and a lower weeding frame. Frame 13, the described upper weeding frame 12 is installed vertically, the described lower weeding frame 13 is installed horizontally, and the lower weeded frame 13 is installed horizontally, which can avoid the limitation of the support plate in the vertical direction, so that the lower weeding frame The weeding roller on the 13 can contact with ground.

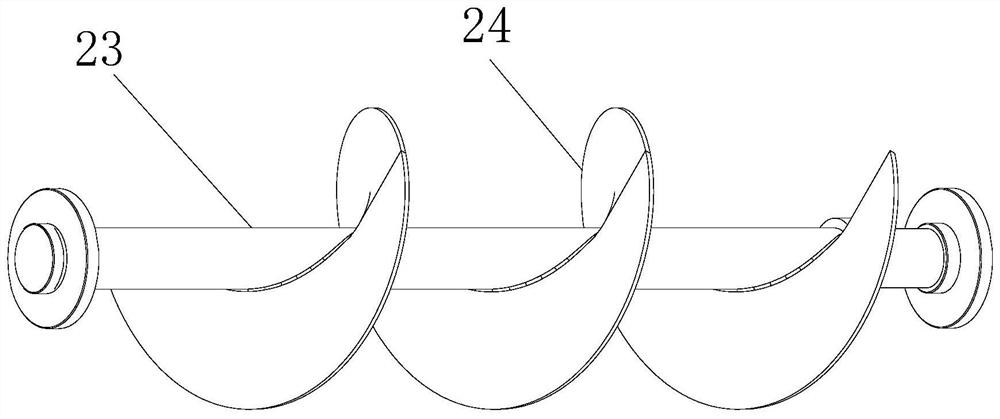

[0029] Both sides of the upper weeding frame 12 and the lower weeding frame 13 are equipped with a rotating shaft 22 through a bearing 21, a weeding roller 23 is installed on the rotating shaft 22, and a spiral cutting blade is installed on the weeding roller 23 24. The spiral cutting blades 24 on ...

Embodiment 2

[0034] see figure 1, this embodiment is a further optimization of Embodiment 1. On the basis of it, the rear side of the weeding opening 11 is provided with a first material guide slope 15, and the rear side of the first material guide slope 15 is equipped with a shovel rack 16. The main body of the shovel frame 16 is a turntable 64, and the outer edge of the turntable 64 is equipped with a plurality of feeding shovels 63 through straight rods at equal angles, and the rear side of the weeder 1 is provided with a material storage box 18, A second material guide slope 17 is arranged between the material storage box 18 and the shovel frame 16, and a conveyor belt 62 is installed on the second material guide slope 17 through a fixed frame 61, and the end of the conveyor belt 62 is located at the storage tank. The top opening of the feed box 18.

[0035] The present application can also collect forage after weeding. After the forage that is twisted in passes through the first mate...

Embodiment 3

[0038] see figure 1 with Figure 5 , this embodiment is a further optimization of Embodiment 1. On the basis of it, the lower weeding frame 13 is adjustable and installed on the weeder 1, and the top of the lower weeding frame 13 is installed with a positioning frame 51, The positioning frame 51 is movable up and down and installed on the housing of the weeding machine 1. The front end cavity of the weeding machine 1 is provided with an adjusting frame 52, and an adjusting screw 53 is installed on the adjusting frame 52. The positioning frame 5. The adjustment screw sleeve 54 is connected with the adjustment screw 53. An adjustment motor 55 is installed on the bottom of the weeder 1. An adjustment shaft 56 is installed on the driving end of the adjustment motor 55. A transmission ramp is installed on the adjustment shaft 56. Gear 57 , the power input end of the adjusting screw 53 is equipped with a driven helical gear 58 , and the driving helical gear 57 is meshed with the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com