Fastener press assembling mistake proofing device and method

An error-proofing and press-fitting technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of visual confusion and wrong press-fitting of finished products, and achieve the effect of eliminating mixed loading and improving the effect of anti-mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

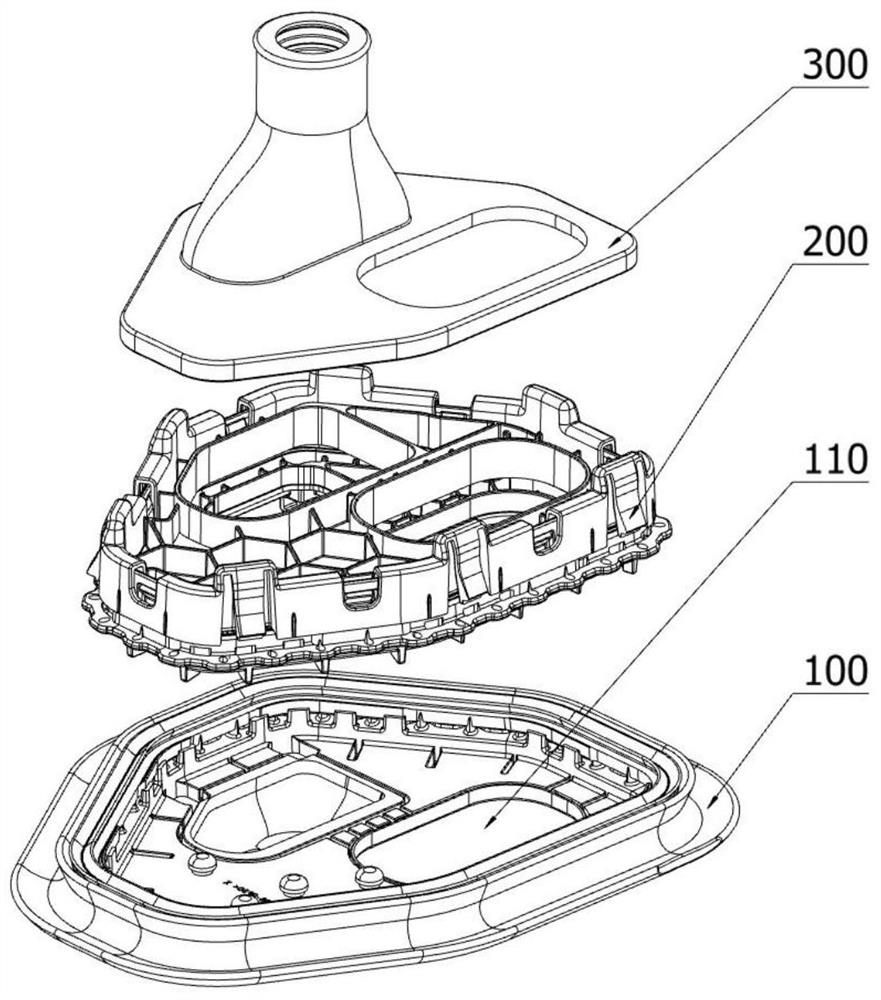

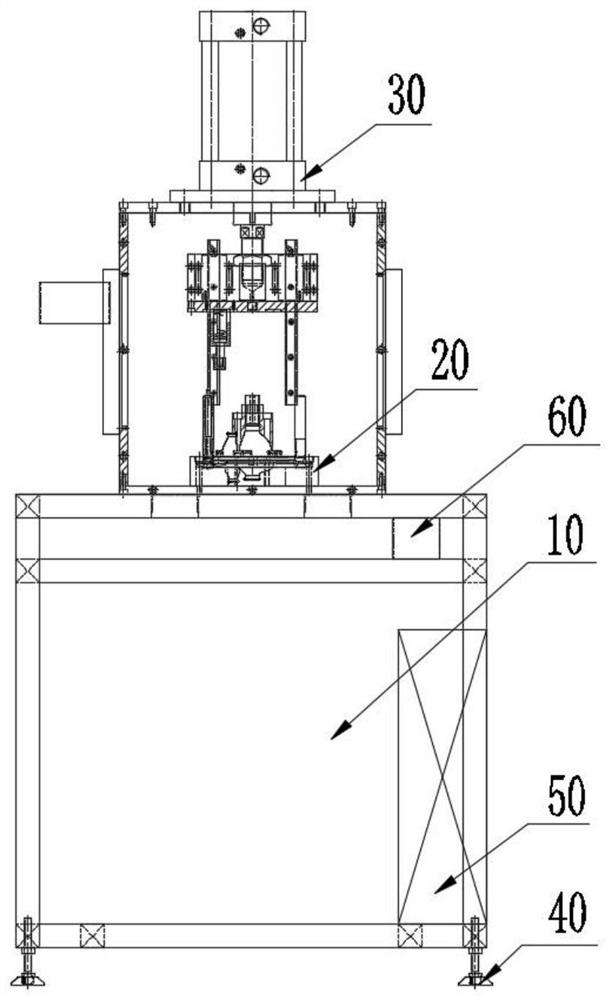

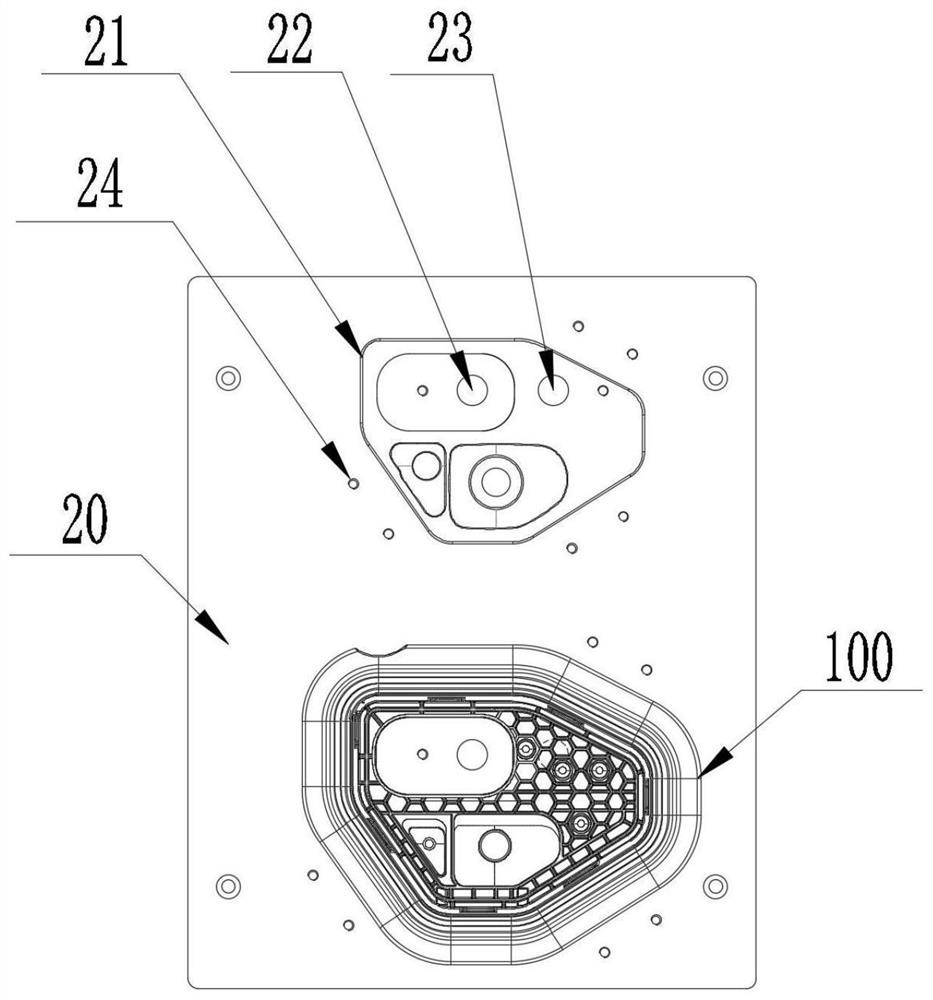

[0041] A fastener press-fit error prevention device, wherein, such as figure 2 , 3 As shown, it includes: a mounting seat 10 and an error-proof mounting platform 20 .

[0042] The error-proof mounting table 20 is fixed or rotatably mounted on the mounting base 10 , and the error-proof mounting table 20 has: a placement part 21 , a first sensor 22 , and a second sensor 23 .

[0043] The placing part 21 is used for placing the rubber lagging part 100 . The first sensor 22 is disposed on the placement part 21 , and the first sensor 22 corresponds to the recessed part 110 of the rubber lagging part 100 . The second sensor 23 is located at the left end of the first sensor 22 , and the second sensor 23 is arranged on the placing part 21 , and corresponds to the other non-hole parts of the rubber lagging part 100 .

[0044]The first sensor 22 and the second sensor 23 move up and down through the telescopic structure, so as to adjust the relative distance between the first sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com