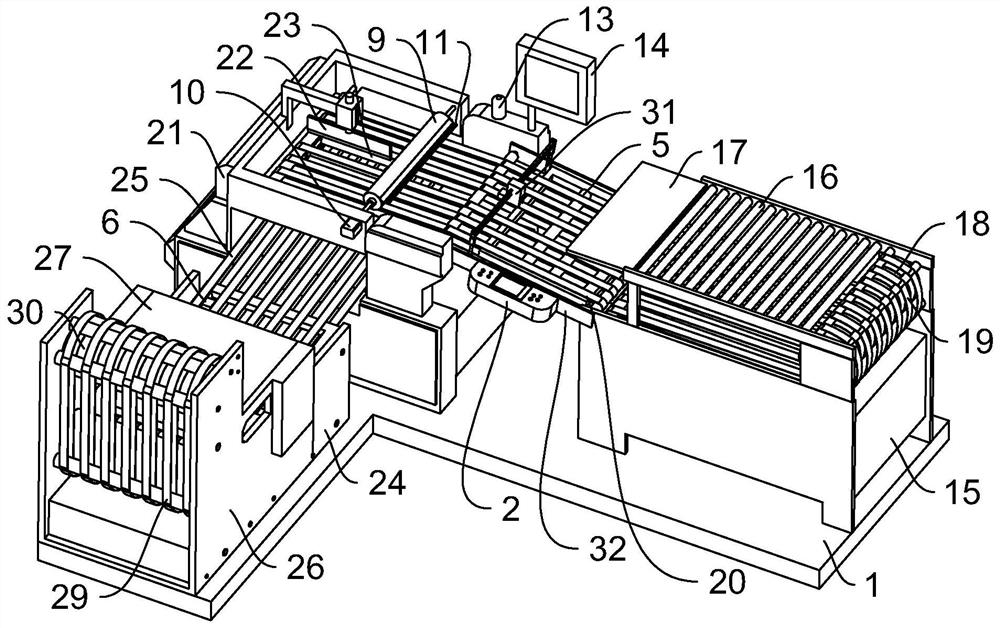

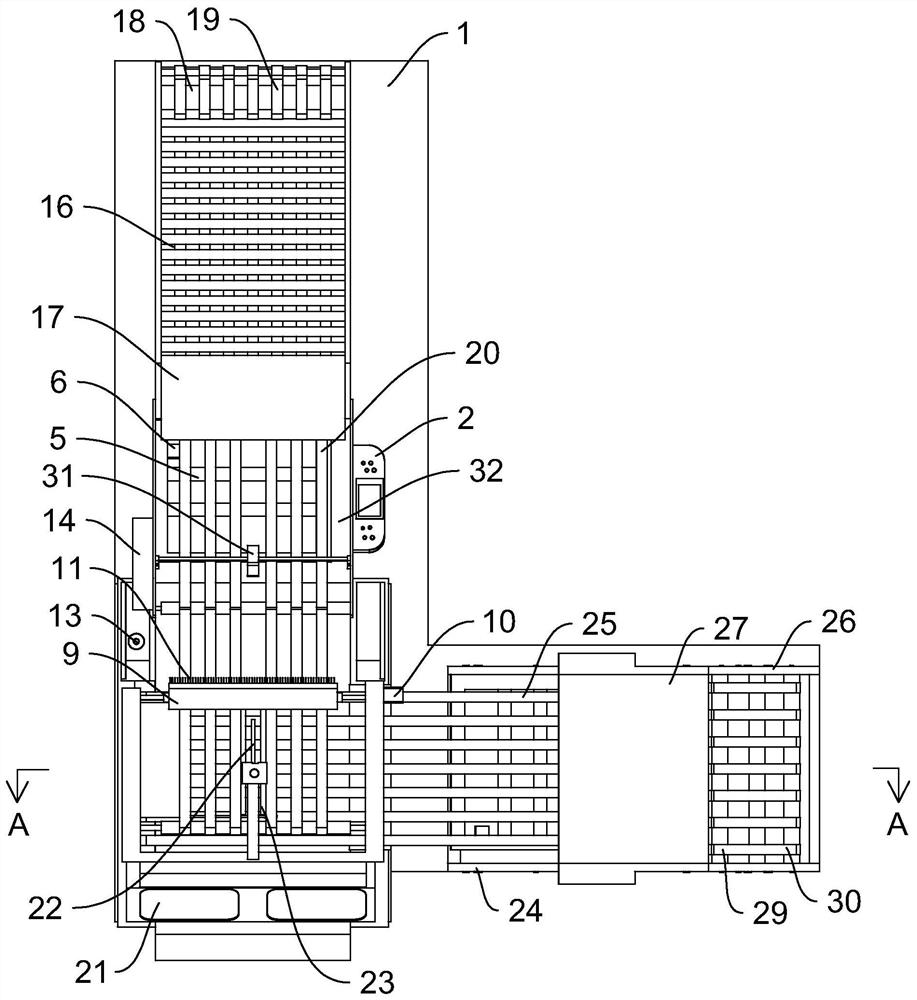

A folding machine defect automatic detection and automatic kick-out system

An automatic detection and folding machine technology, applied in the field of folding machines, can solve the problems of slow paper transportation or paper accumulation, affecting the service life of the folding machine, affecting the aesthetics of the paper, etc., so as to reduce the folding angle of the paper and reduce the existence of defects. , Guarantee the effect of smooth transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0064] The difference between this embodiment and Embodiment 1 is:

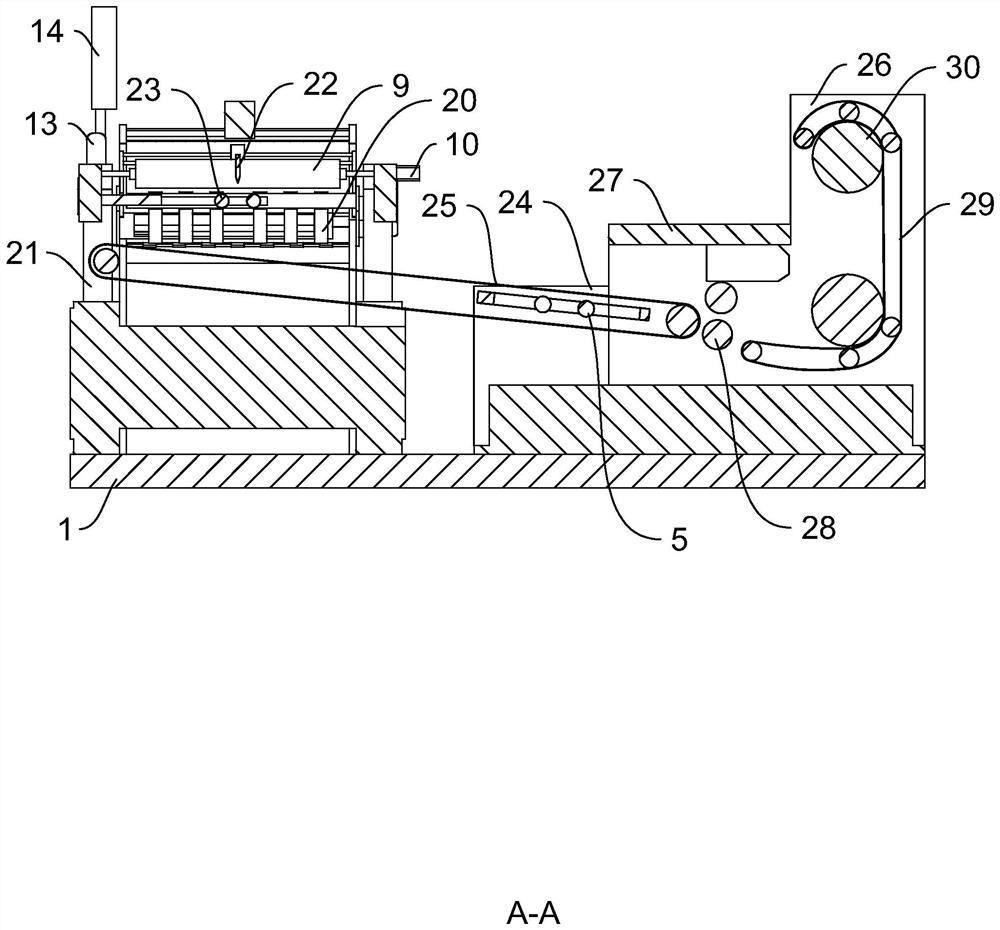

[0065] Paper transportation abnormal detection mechanism is paper weight detection mechanism, refer to Figure 5 and Image 6 The paper weight detection mechanism includes a weighing device 7 and a weighing sensor 8. The weighing device 7 is fixed inside the body 1. The weighing device 7 adopts a suspension weighing frame. On the first conveying platform 32 and the second conveying platform 24 Both are installed with suspended weighing frames through bolts, the beams and load cells of the two suspended weighing frames are respectively arranged inside the first conveyor belt 20 and the second conveyor belt 25, and the beams of the two suspended weighing frames are respectively attached to the On the conveying surfaces of the first conveying belt 20 and the second conveying belt 25 , the load cell 8 is used to sense the weight of the paper on the weighing device 7 , acquire and transmit the current paper weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com