A kind of solid warm mixing modified double-effect asphalt modifier and preparation method thereof

An asphalt modifier and warm mixing technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of inability to achieve asphalt mixture road performance, modified asphalt performance decay, increase production costs, etc., to achieve improvement The effects of high temperature shear resistance and impact resistance, improved fluidity, and improved low temperature flex resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

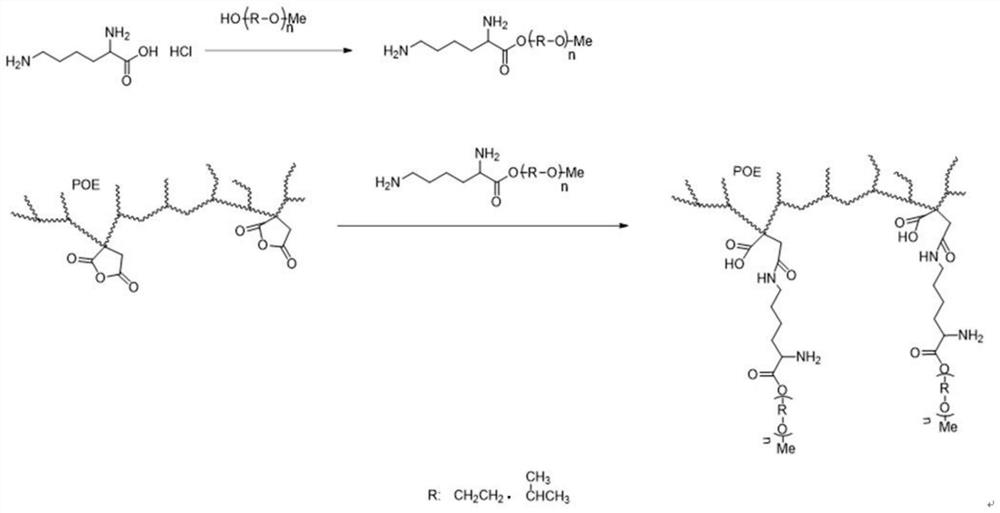

[0027] This embodiment provides a solid warm-mix modified double-effect asphalt modifier, which is mainly prepared from the following raw materials: MAH-g-POE, lysine hydrochloride and polyethylene glycol monomethyl ether.

[0028] The preparation method of a solid warm-mix modified double-effect asphalt modifier in this example is as follows:

[0029] Step 1, add 300mL anhydrous toluene solvent in 2L there-necked flask, add 219.2g lysine hydrochloride and 350g MPEG350 (being the polyethylene glycol monomethyl ether of molecular weight 350) and stir, esterification takes place, The reaction was refluxed until anhydrous was formed; then solid sodium bicarbonate was added to continue stirring the reaction until no gas was released, and then the reaction was stopped; the reaction liquid was filtered and washed twice with toluene solution; then vacuum was carried out under the experimental conditions of 80°C and 0.98MPa Drying obtains 507g polyethylene glycol monomethyl ether lysi...

Embodiment 2

[0033] This embodiment provides a solid warm-mix modified double-effect asphalt modifier, which is mainly prepared from the following raw materials: MAH-g-POE, lysine hydrochloride and polypropylene glycol monomethyl ether.

[0034] The preparation method of a solid warm-mix modified double-effect asphalt modifier in this example is as follows:

[0035] Step 1, add 300mL anhydrous toluene solvent in the three-necked flask of 2L, add 219.2g lysine hydrochloride and 400g MPPG400 (polypropylene glycol monomethyl ether that molecular weight is 400) and stir, esterification takes place, and reaction is refluxed to Anhydrous was formed; then solid sodium bicarbonate was added to continue stirring the reaction until no gas was released and the reaction was stopped; the reaction solution was filtered and washed twice with toluene solution; then vacuum-dried under the experimental conditions of 80°C and 0.98MPa to obtain 557g Polypropylene glycol monomethyl ether lysine ester;

[0036...

Embodiment 3

[0039] This example provides a solid warm-mix modified double-effect asphalt modifier, which is mainly prepared from the following raw materials: MAH-g-POE, lysine hydrochloride, polyethylene glycol monomethyl ether and polypropylene glycol A mixture of monomethyl ethers.

[0040] The preparation method of a solid warm-mix modified double-effect asphalt modifier in this example is as follows:

[0041] Step 1, in the there-necked flask of 2L, add 300mL solvent anhydrous toluene, add 274.0g lysine hydrochloride and 200g MPEG400 (being the polyethylene glycol monomethyl ether that molecular weight is 400), 300g MPPG600 (being that molecular weight is 600 Polypropylene glycol monomethyl ether) is stirred, and esterification reaction takes place, and reaction is refluxed to anhydrous generation; Then add sodium bicarbonate solid and continue to stir reaction until no gas is released, then stop reaction; Reaction solution is filtered, washed with toluene solution for 2 Then carry o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com