Electric floor mopping machine

A mopping machine, electric technology, applied in the direction of cleaning carpets, cleaning floors, machine parts, etc., can solve the problems of reducing labor intensity, reliability, durability, poor control performance, etc., to achieve high mopping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

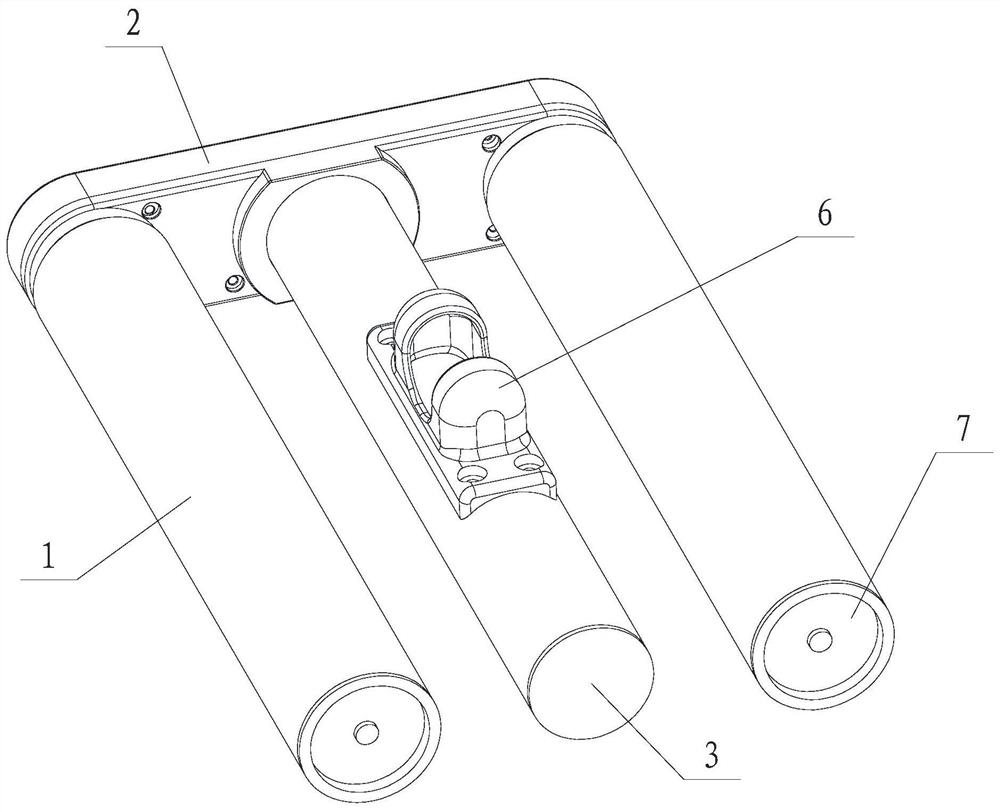

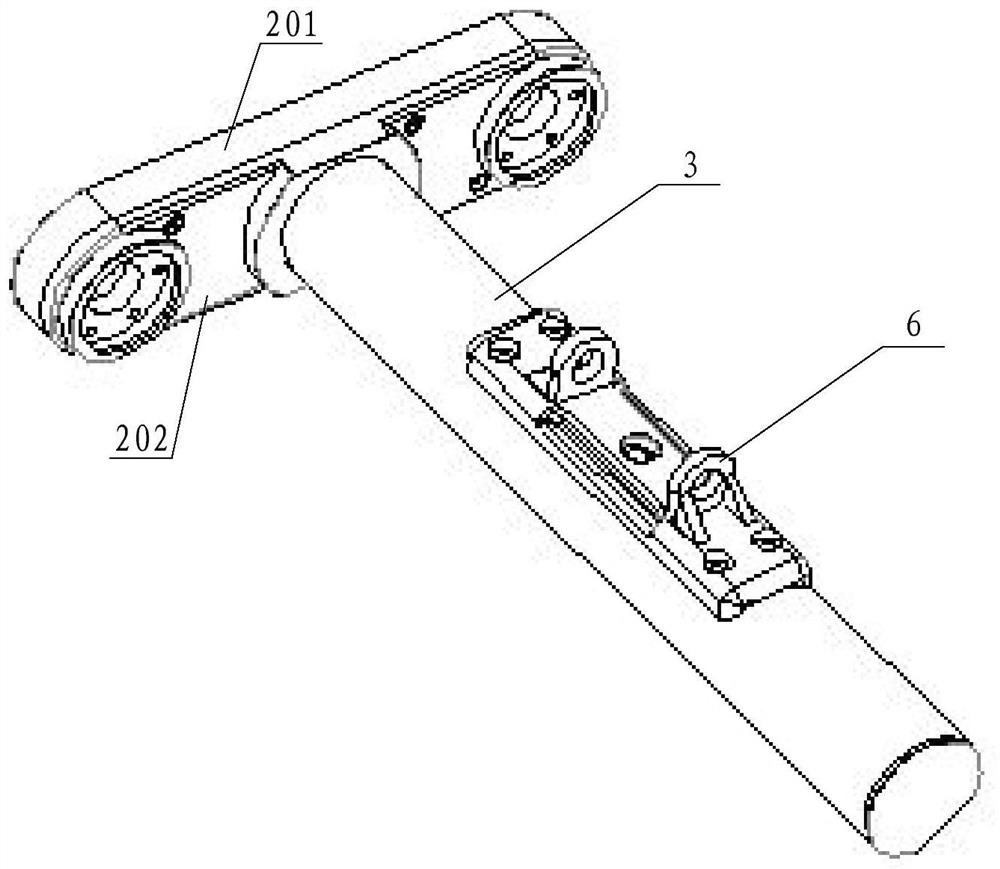

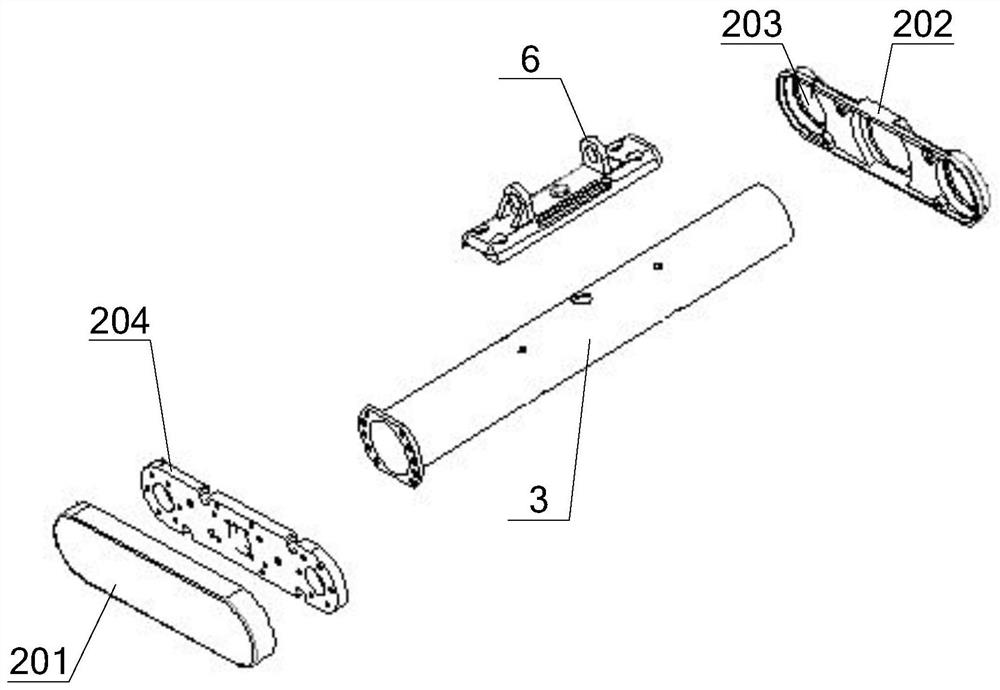

[0040] Such as Figure 1~4 and Figures 10-14 As shown, the fixed plate assembly 2 of the present embodiment includes a fixed plate 204 and an outer cover, the outer cover is divided into an outer cover plate 201 and an inner cover plate 202, and the inner and outer cover plates 202, 201 are connected to form a hollow structure outer cover, and the fixed plate 204 is fixed in the outer cover; three holes 203 are opened on the inner cover 202, the main bracket 3 passes through the hole 203 in the middle, and the other two holes 203 are used for the support components on both sides to pass through. The main bracket 3 and the supporting components on both sides are installed on the fixed plate 204, and the transmission mechanism is housed in the outer cover. A connecting piece 6 is installed on the main bracket 3, and the operating handle of the mopping machine is connected with the connecting piece 6 through a universal joint.

[0041] The transmission mechanism of this embodi...

Embodiment 2

[0047] Such as Figure 1~3 , Figure 5-6 , Figure 12 and Figures 14 to 15 As shown, the difference between this embodiment and Embodiment 1 is that the transmission member 110 of this embodiment is directly connected to the outer drum 102 for transmission, and one end of the inner drum 101 of this embodiment is conical, and the other end is cylindrical. The inside of the part is rotationally connected with the bearing seat 105 through the bearing C108, and the conical part facilitates the insertion of the outer cylinder 102. The difference between the locking member 109 of this embodiment and the first embodiment is that the locking member 109 is located outside the inner drum 101 . In this embodiment, the transmission member 110 is located outside the inner drum 101 and inside the outer drum 102 , and the end of the transmission member 110 away from the fixed plate assembly 2 is evenly distributed with engaging teeth 113 along the circumferential direction. An engaging ...

Embodiment 3

[0049] Such as Figure 1~3 , Figure 7-8 and Figures 10-14 As shown, the difference between this embodiment and Embodiment 1 is that the support assembly of this embodiment includes a bearing seat 105 and a support member 112, and the other end of the bearing seat 105 and the locking member 109 screwed to the end are located on the inner drum 101 Inside the end close to the fixed plate assembly 2 ; the support member 112 is sleeved on the main shaft 104 and keyed to the main shaft 104 , the support member 112 is located on the side of the locking member 109 away from the fixed plate assembly 2 . The inner drum 101 is sleeved on the support member 112 and supported by the support member 112 . The transmission member 110, the inner drum 101, the outer drum 102, the transmission between the transmission member 110 and the inner drum 101, and the transmission between the inner drum 101 and the outer drum 102 in this embodiment are all the same as in the first embodiment, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com