Fabricated wall with bottom junction box mounted on outdoor side and construction method of fabricated wall

A prefabricated, outdoor-side technology, used in building structures, walls, buildings, etc., can solve the problem that the location of the junction box cannot meet user requirements, and achieve the effect of reducing manufacturing difficulty, improving production efficiency, and facilitating later maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

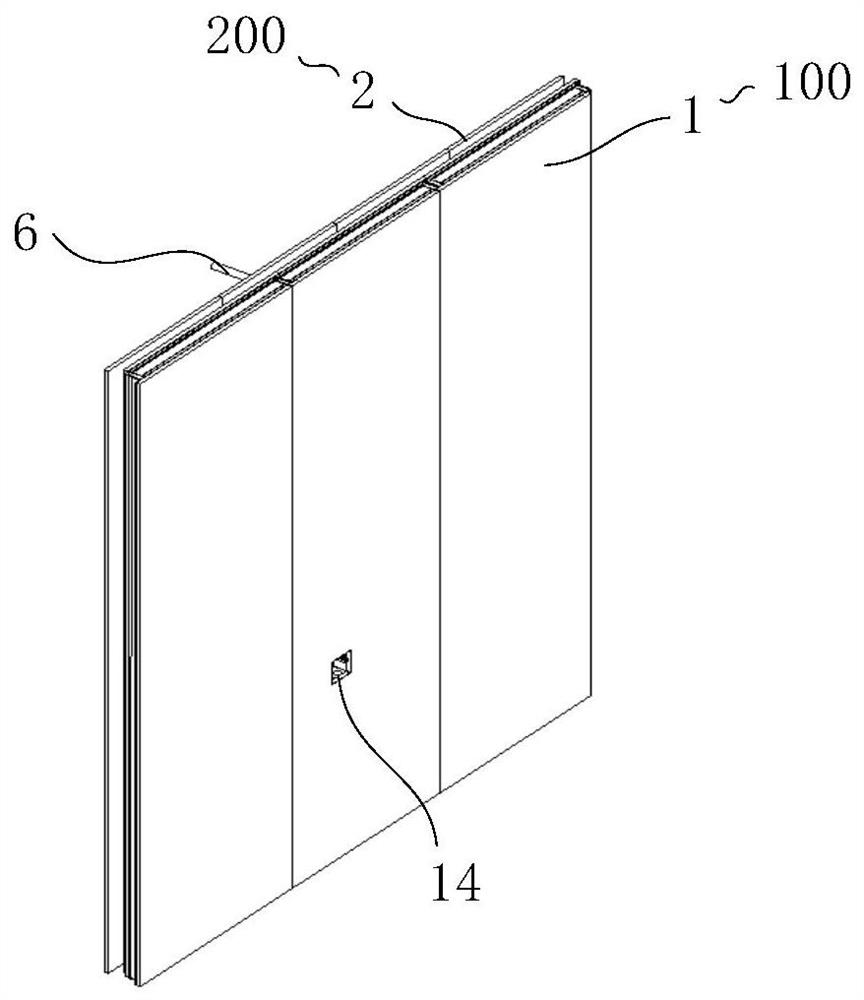

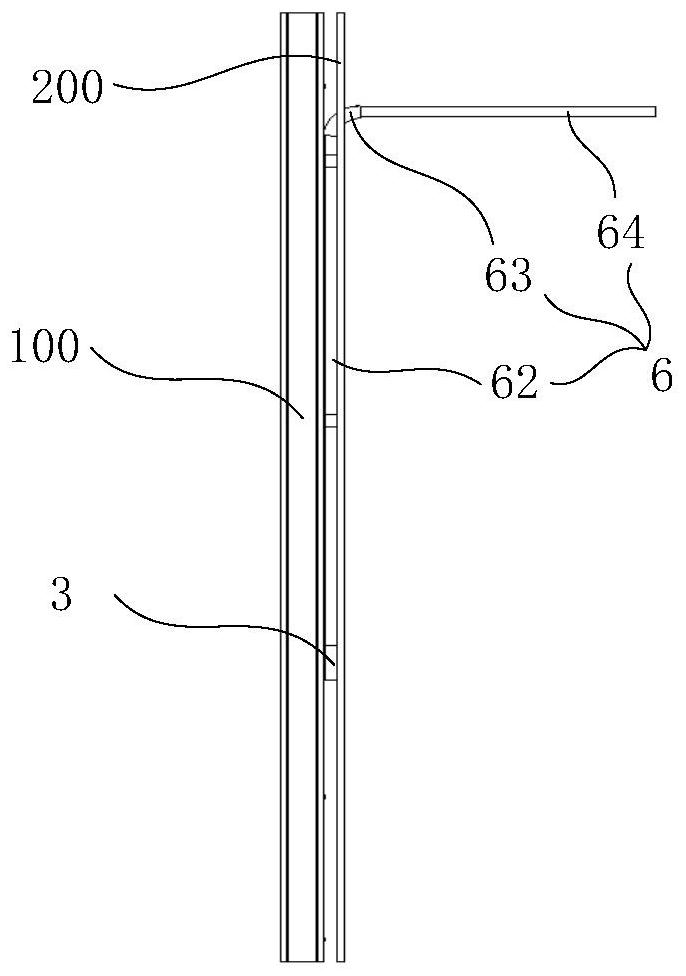

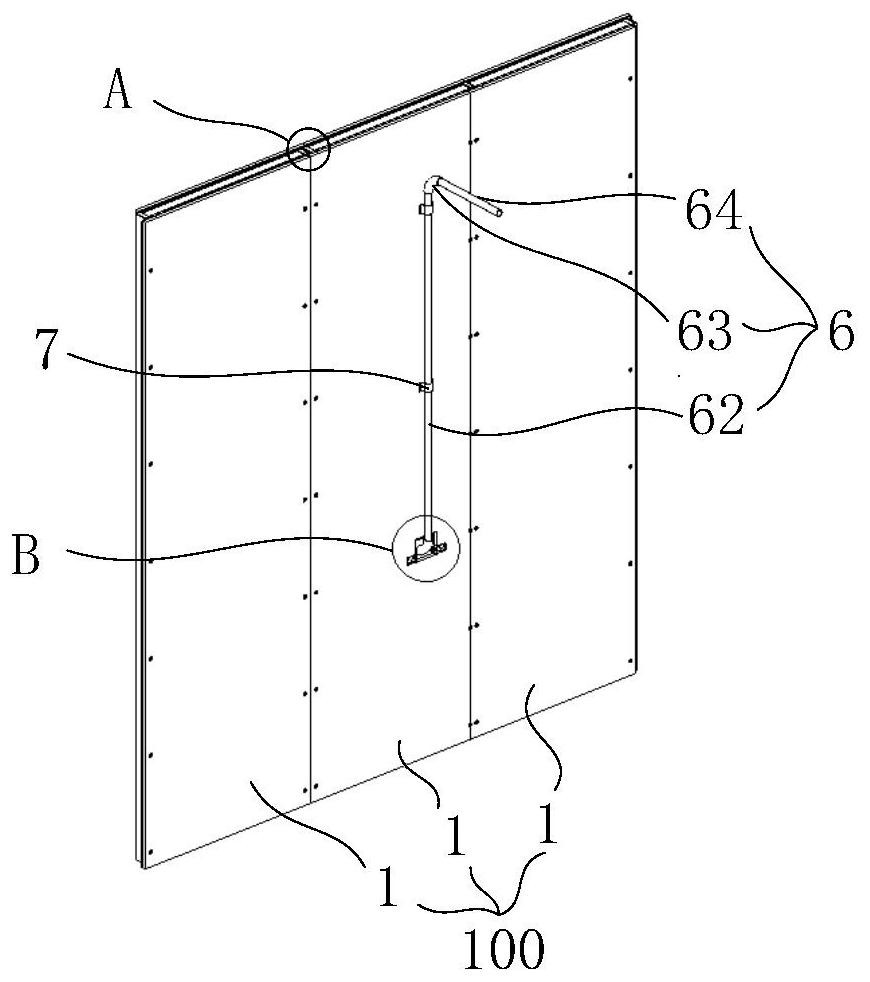

[0065] In some embodiments, refer to Figure 17 , in the prefabricated wall (between the main wall 100 and the wall decoration board 200 ), a large number of line pipes 6 or water pipes are usually arranged to meet the electricity and water requirements of the building itself.

[0066] In some embodiments, refer to Figure 18 , Figure 19 and Figure 20 , the side wall of the decorative wall panel 200 close to the main wall 100 is fixed with an elastic clip 8, the elastic clip 8 has a C-shaped slot 8a on the side close to the main wall 100, and the C-shaped slot 8a is locked with the wire tube 6 Then, the decorative wall panel 200 is fixed on the surface of the main wall 100 . Compared with the fixed structure that cooperates with each other between the decorative wall panel 200 and the main wall 100 , in this embodiment, through the cooperation of the elastic clip 8 and the wire tube 6 , it only needs to be close to the decorative panel 200 . One side of the main wall 100...

Embodiment 2

[0069] In some embodiments, there may be some areas in the prefabricated wall that are not provided with or only have a small number of conduits 6 . In this case, the distribution of conduits 6 is insufficient to provide attachment positions for the elastic clips 8 . At this time, the wire duct 6 only for fixing the decorative wall panel 200 may be installed on the surface of the main wall 100 . However, it will increase the usage of the line pipe 6 and increase the overall construction cost of the prefabricated wall.

[0070] For the above reasons, in some embodiments, refer to Figure 21 , a first clamping structure 9 is provided between the decorative wall panel 200 and the main wall 100, and the first clamping structure 9 includes a buckle 9a and a clamping head 9b. The buckle 9a has a circular groove, and the inner side of the opening of the groove is provided with a clamping flange 93; The outer side of the claw 95 is provided with a clamping protrusion 951 that cooper...

Embodiment 3

[0075] The first clamping structure 9 is fixed point-to-point. When the area of the sub-decorative board 2 is large and a plurality of first clamping structures 9 need to be arranged between the sub-decorative board 2 and the main wall 100, the first clamping structure The positional accuracy of the structure 9 is required to be relatively high, which affects the installation efficiency of the sub-decorative panel 2, which in turn affects the overall construction speed of the prefabricated wall.

[0076] Based on the above reasons, in this embodiment, a second clamping structure 20 is provided between the decorative wall panel 200 and the main wall 100 , and is fixedly connected by the second clamping structure 20 . refer to Figure 25 , the second clamping structure 20 includes a square tube 201, the square tube 201 includes a first tube wall and a second tube wall arranged oppositely, the first tube wall and the surface of the main wall 100 are attached and fixed, along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com