A double top feeding and discharging device and its control method

A material feeding and discharging, top-type technology, applied in metal processing and other directions, can solve the problems of scrapped parts, easily damaged workpieces by manipulators, etc., and achieve the effect of improving stable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

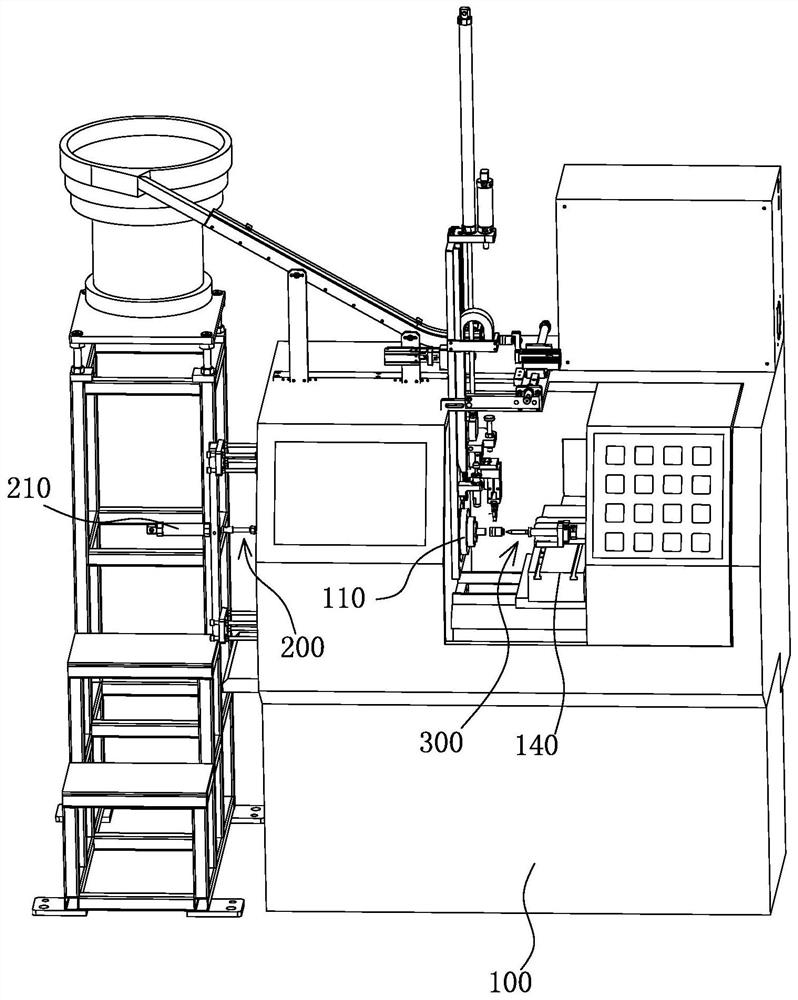

[0034] Such as figure 1 — figure 2 and Figure 5 As shown, a double-top feeding and discharging device of the present invention includes a casing 100 , a clamping platform 110 , a workbench 140 , a left feeding mechanism 200 and a right feeding mechanism 300 .

[0035] A clamping platform 110 is provided in the casing 100, and a left feeding mechanism 200 is installed in the casing 100, and the left feeding mechanism 200 moves through the clamping platform 110; the right feeding mechanism 300 is installed in the casing, and the right feeding mechanism 300 The mechanism can move relative to the casing. The central axis of the left feeding mechanism 200 coincides with the central axis of the right feeding mechanism 300. When the workpiece is between the left feeding mechanism 200 and the right feeding mechanism 300, the left feeding mechanism 200 and the right feeding mechanism 300 transfers the workpiece to the clamping table 110, and further, a workbench for installing the ...

Embodiment 2

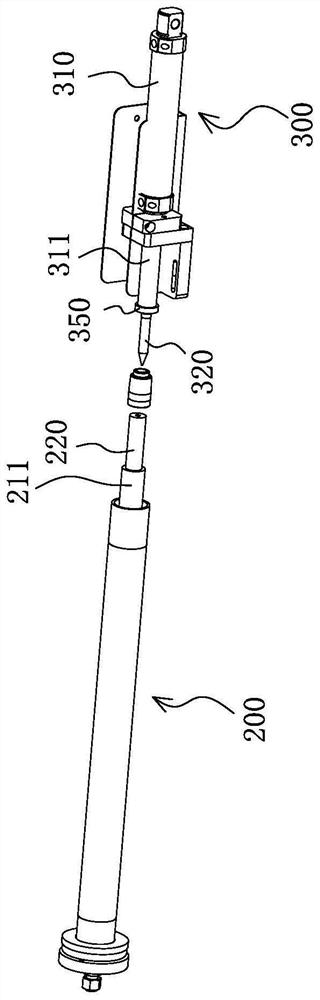

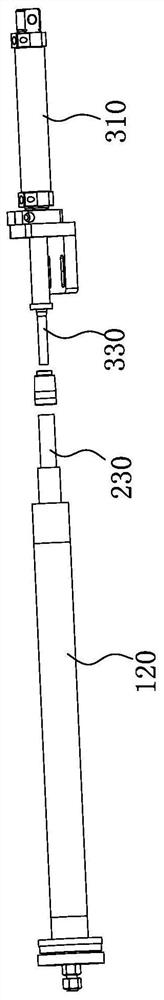

[0041] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment changes part of the structures of the left feeding mechanism 200 and the right feeding mechanism 300 .

[0042] In this embodiment, the workpiece is a solid cylindrical workpiece.

[0043] Specifically, one end of the fourth moving rod 211 is provided with a left push column 230, and one end of the fifth moving rod 311 is provided with a right pushing post 330. When the workpiece is located between the fourth moving rod 211 and the fifth moving rod 311, the first The five-cylinder 310 pushes the fifth moving rod 311 and the right prop 330 to move until the right prop 330 touches an end face of the workpiece. At the same time, the fourth moving rod 211 drives the left prop 230 to move until the left prop 230 touches Hold the other end surface of the workpiece, that is, make the left top column 230 and the right top column 330 clamp the workpiece between the two, so...

Embodiment 3

[0045] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment changes part of the structures of the left feeding mechanism 200 and the right feeding mechanism 300 .

[0046] In this embodiment, the workpiece is a solid cylindrical workpiece or the workpiece is a tubular workpiece.

[0047] Specifically, one end of the fourth moving rod 211 is provided with a plurality of claws 240 in a circular array along its central axis, one end of the fifth moving rod 311 is provided with a moving block 340, and the moving block 340 is provided with a pair of long rods 341 and a For the short rods 342, two long rods 341 are symmetrical to the center of the moving block 340, two short rods 342 are symmetrical to the center of the moving block 340, and the circumferential angle between the long rods 341 and the adjacent short rods 342 is a right angle.

[0048] When the workpiece is located between the fourth moving rod 211 and the fifth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com