Dental prosthesis veneering porcelain molding process

A technology for dental restoration and molding technology, applied in the direction of dentures, etc., can solve the problems of lack of porcelain at the bottom of the bridge, reduce the quality of the restoration, and the inability of the slurry to enter effectively, and achieve the effect of ensuring the quality of the molding, speeding up the efficiency, and eliminating the lack of porcelain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the manufacturing process of dental restorations, the treatment of surface veneer is particularly important. How to process the undercut surface and how to solve the problems that the bottom of the restoration cannot be covered by veneer is particularly important to ensure the quality of veneer and improve manufacturing efficiency. The purpose of the present invention is to propose a porcelain veneer molding process for dental restorations, which can greatly improve the processing efficiency of the entire veneer porcelain and the quality of sintered molding.

[0040] The present invention will be further described in detail below with reference to the examples and figures, but the embodiments of the present invention are not limited thereto.

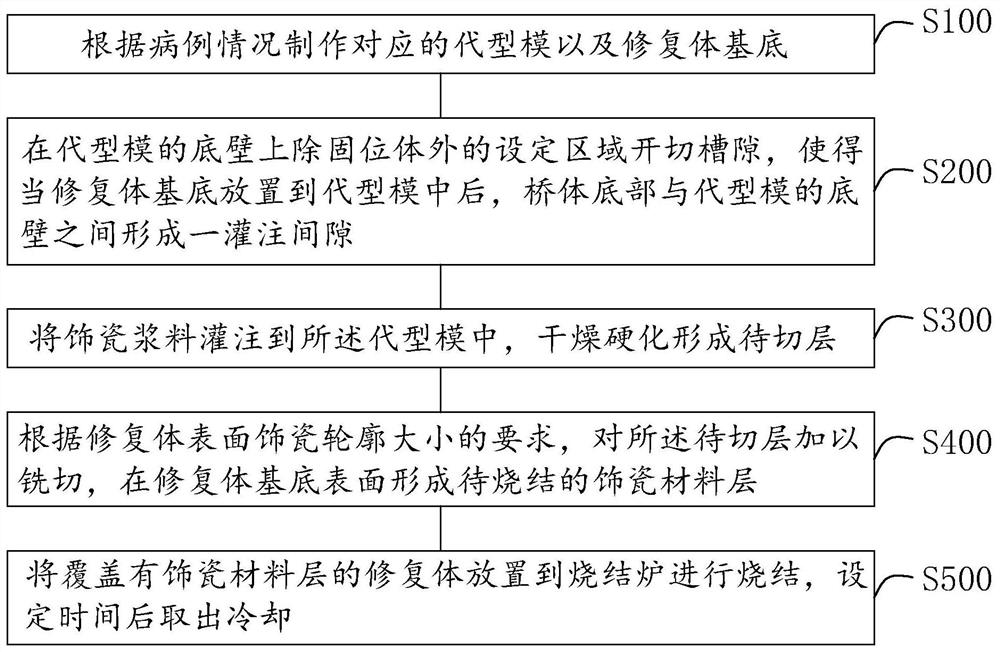

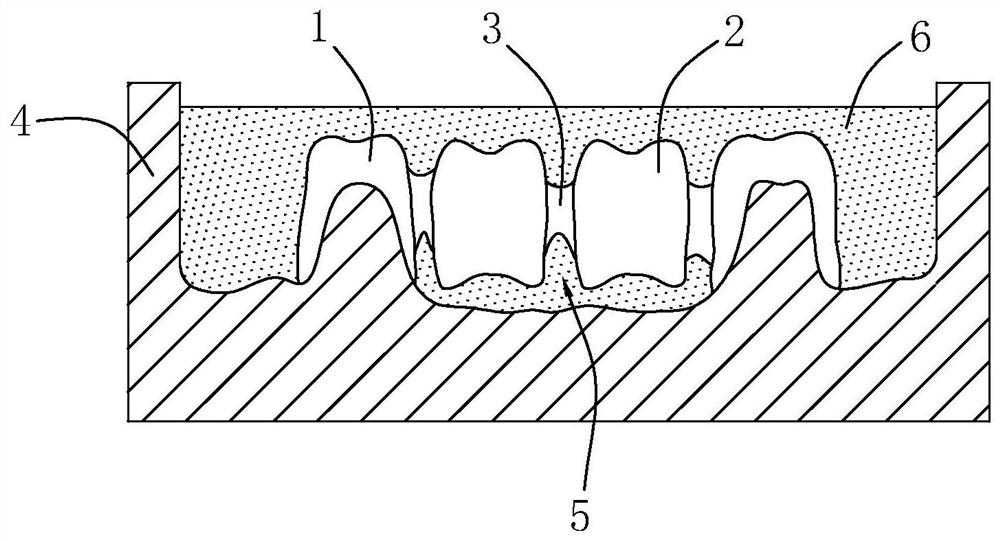

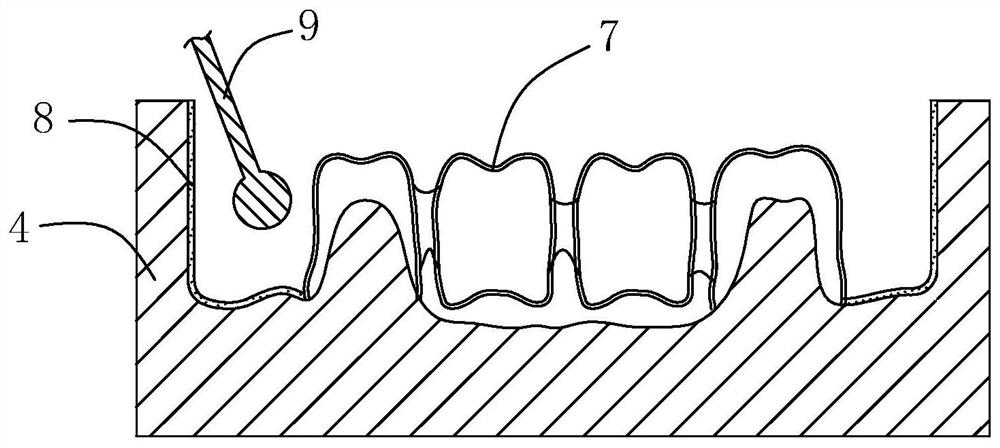

[0041] Such as figure 1 with figure 2 Shown, a kind of dental prosthesis veneer molding process, comprises the following steps:

[0042] S100, making the corresponding dummy model 4 and the restoration base according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com