CNC dual-main-shaft transmission device

A transmission device, dual-spindle technology, applied in feeding devices, large fixed members, metal processing machinery parts, etc., can solve the problems of difficult mechanism design, decreased processing accuracy, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Before the present invention is described in detail, it should be noted that in the following description, similar elements are represented by the same numbers.

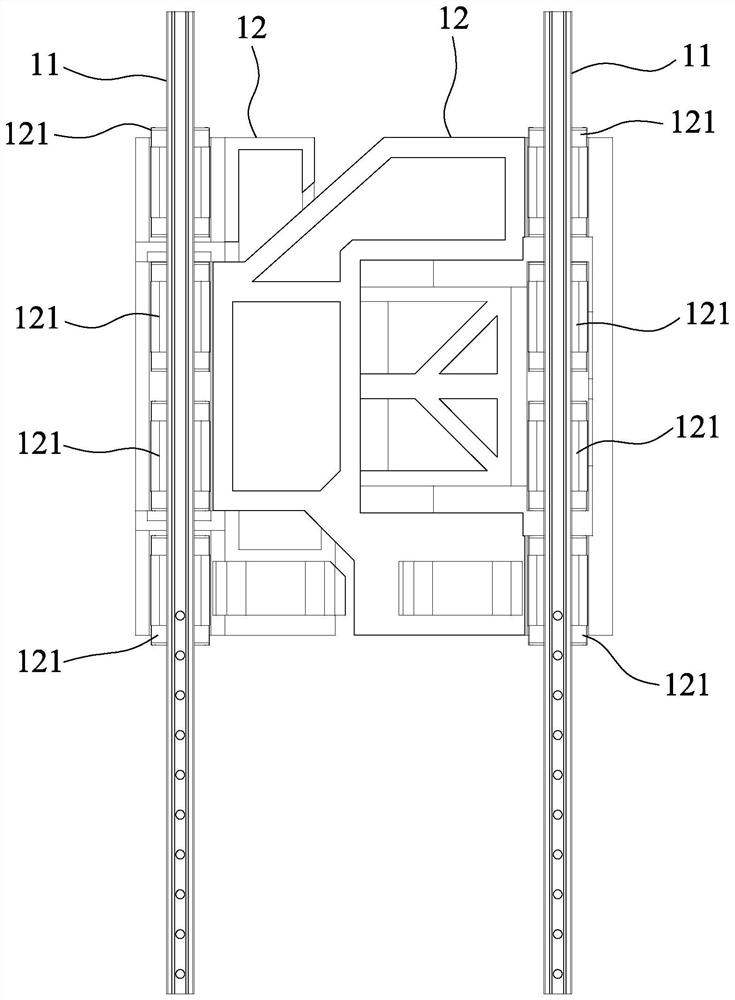

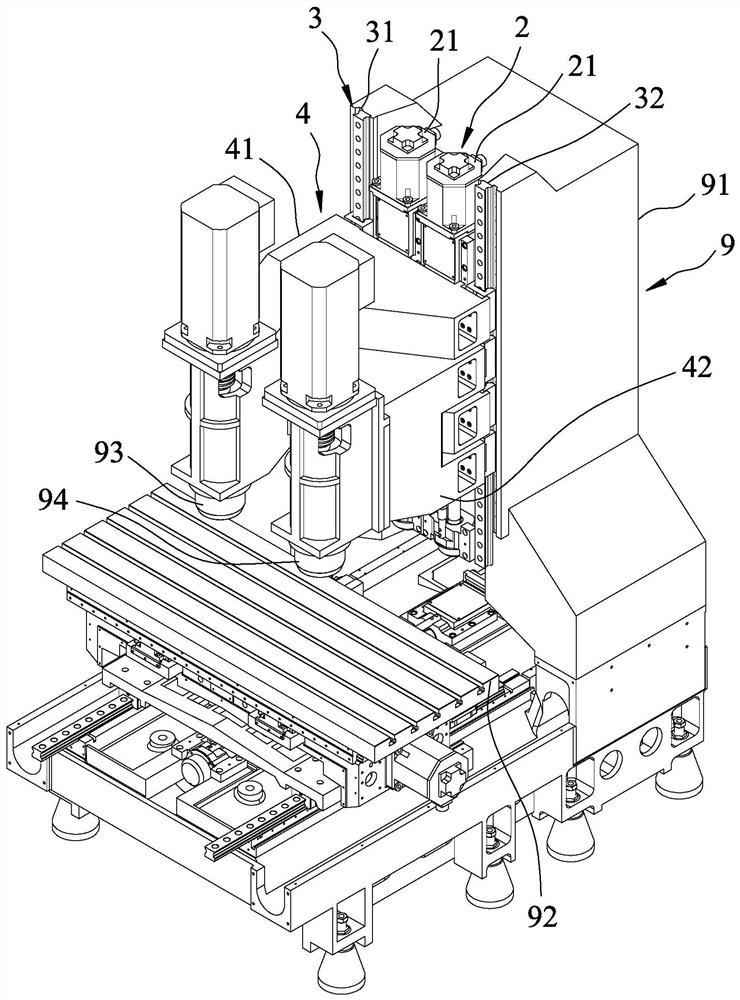

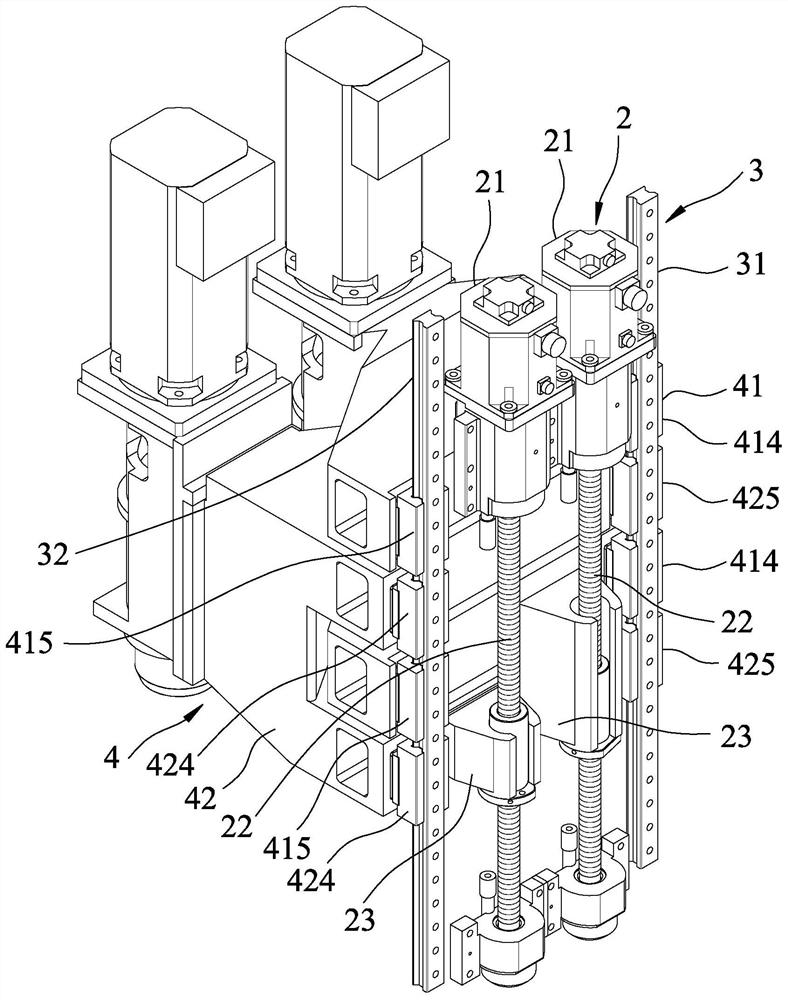

[0030] Refer to figure 2 versus image 3 , A first embodiment of the CNC dual-spindle transmission device of the present invention is suitable for use in a CNC dual-spindle machining machine 9 with a base 91, a work platform 92, a first spindle 93 and a second spindle 94, It includes a power unit 2, a linear rail unit 3, and a sliding seat unit 4.

[0031] The power unit 2 is arranged on the base 91, and includes two motors 21 arranged in the left-right direction, two screws 22 that are driven to rotate by the motors 21, and two respectively movable up and down. The nut seat 23 of the screw 22. Among them, the directional terms used in this case are all based on figure 2 and Image 6 The direction in is used as a reference.

[0032] The linear rail unit 3 includes two linear rails extending up and down and spaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com